Low-bounce ice-cold breathable sponge and preparing process thereof

A low-rebound, cold technology, applied in the field of sponge processing and preparation, can solve problems such as temperature rise, affecting human comfort, and sponges are easy to absorb heat, etc., to achieve good low resilience, facilitate large-scale production, and simple and efficient preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

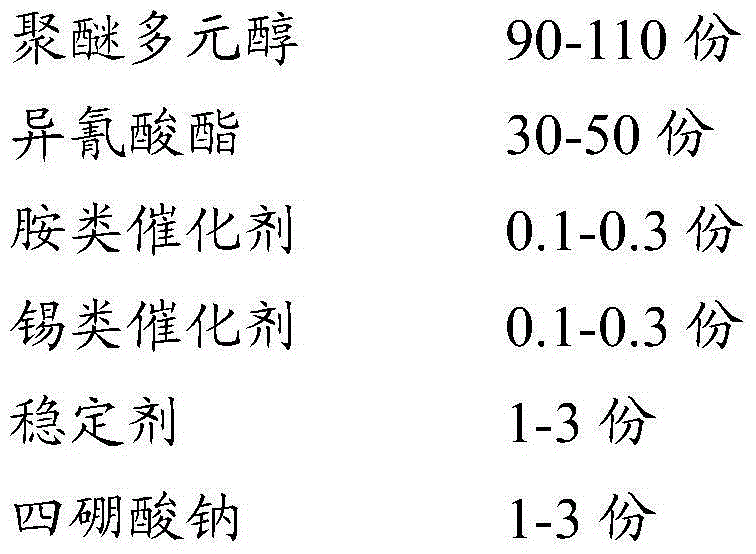

[0030] Take the following components by weight, and use raw material tanks for batching: 90 parts of polyether polyol with a hydroxyl value of 230-306, 50 parts of isocyanate TDI80, 0.1 part of amine catalyst A33, and 0.3 parts of tin catalyst T9 1 part of silicone oil, 3 parts of sodium tetraborate, and 1 part of zinc oxide powder. The above-mentioned components are prepared in a raw material tank and then sent to the reaction kettle for mixing. The stirring speed is 3000r / min and the temperature is 21°C. Then the stirred mixture is sent to the foaming box for aging and film removal. 100s, process and cut the sponge obtained after aging and stripping into finished products.

Embodiment 2

[0032] Take the following components by weight, and use raw material tanks for batching: 110 parts of polyether polyols with a hydroxyl value of 230-306, 30 parts of isocyanate TDI80, 0.3 parts of amine catalyst A33, and 0.1 parts of tin catalyst T9 3 parts of silicone oil, 1 part of sodium tetraborate, and 3 parts of zinc oxide powder. The above-mentioned components are prepared in a raw material tank and then sent to the reaction kettle for mixing. The stirring speed is 5000r / min and the temperature is 23°C. Then the stirred mixture is sent to the foaming box for aging and stripping. The aging time is 150s, process and cut the sponge obtained after aging and stripping into finished products.

Embodiment 3

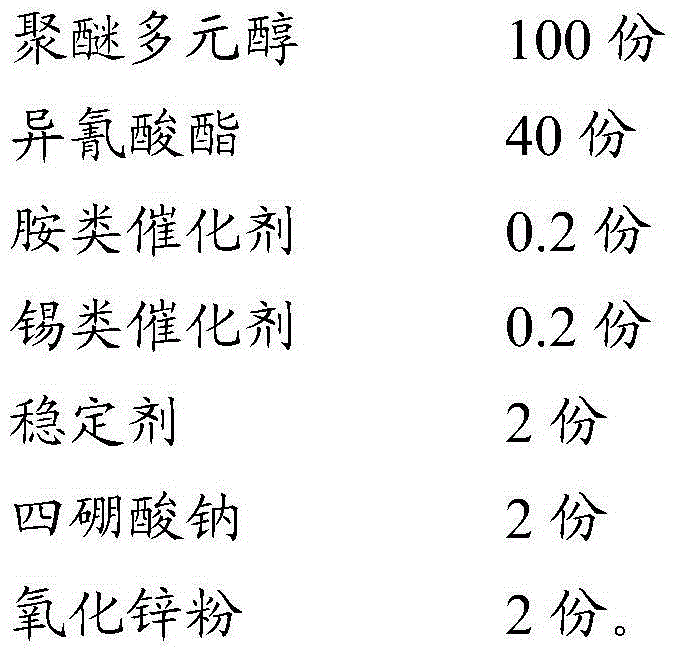

[0034] Take the following components by weight, and use raw material tanks for batching: 100 parts of polyether polyol with a hydroxyl value of 230-306, 40 parts of isocyanate TDI80, 0.2 parts of amine catalyst A33, and 0.2 parts of tin catalyst T9 2 parts, silicone oil 2 parts, sodium tetraborate 2 parts, zinc oxide powder 2 parts. The above-mentioned components are prepared in a raw material tank and then sent to the reactor for mixing. The stirring speed is 4000r / min and the temperature is 22°C. Then the stirred mixture is sent to the foaming box for aging and stripping. The aging time is 120s, process and cut the sponge obtained after aging and stripping into finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com