Caisson composite foundation provided with suction type apron shells and semi-rigid connection piles

A composite foundation, semi-rigid technology, used in caisson, foundation structure engineering, construction and other directions, can solve the problems of limited vertical bearing capacity and large vertical deformation of foundation, improve anti-slip and anti-overturning ability, avoid easy Destruction, smooth sinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

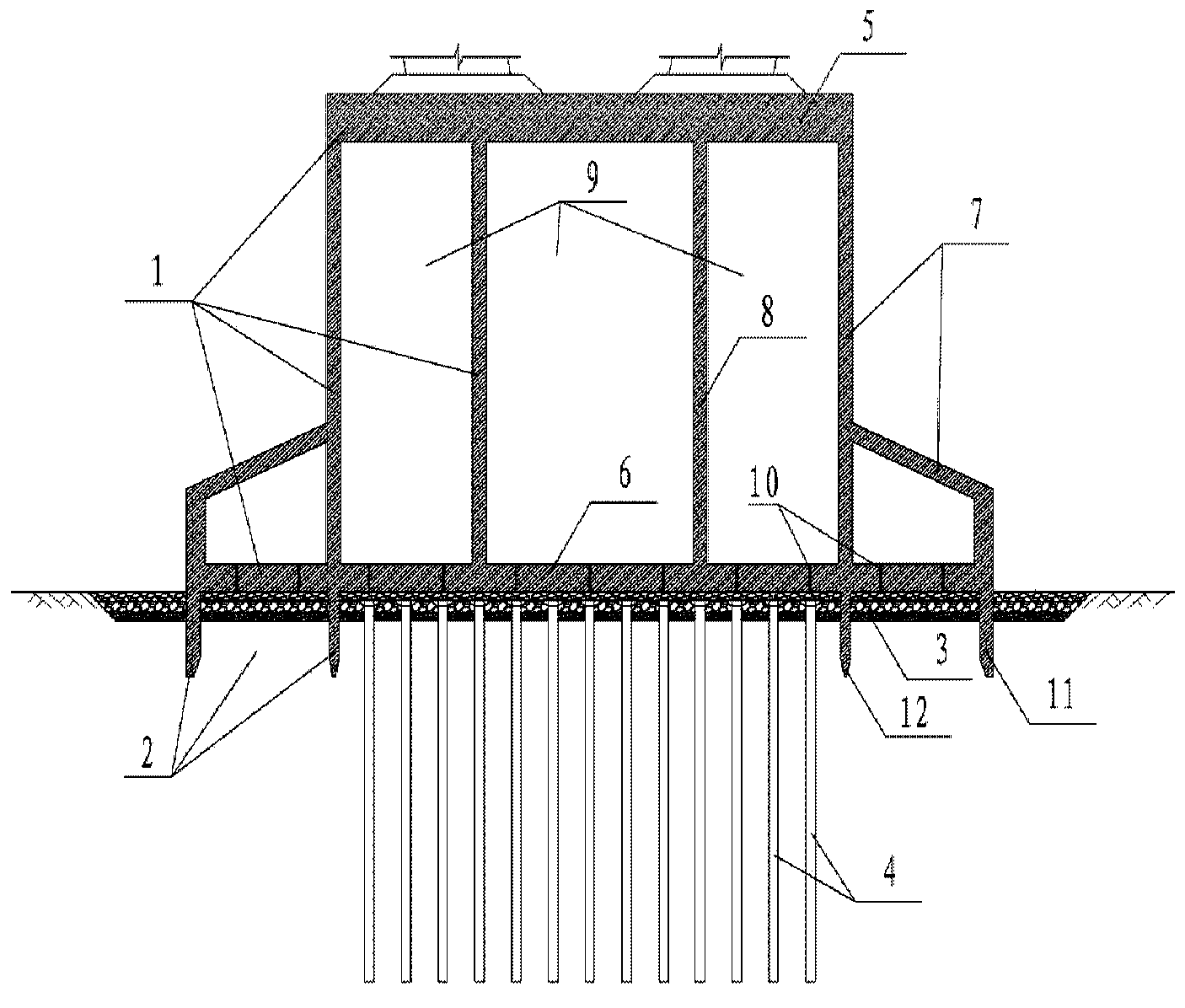

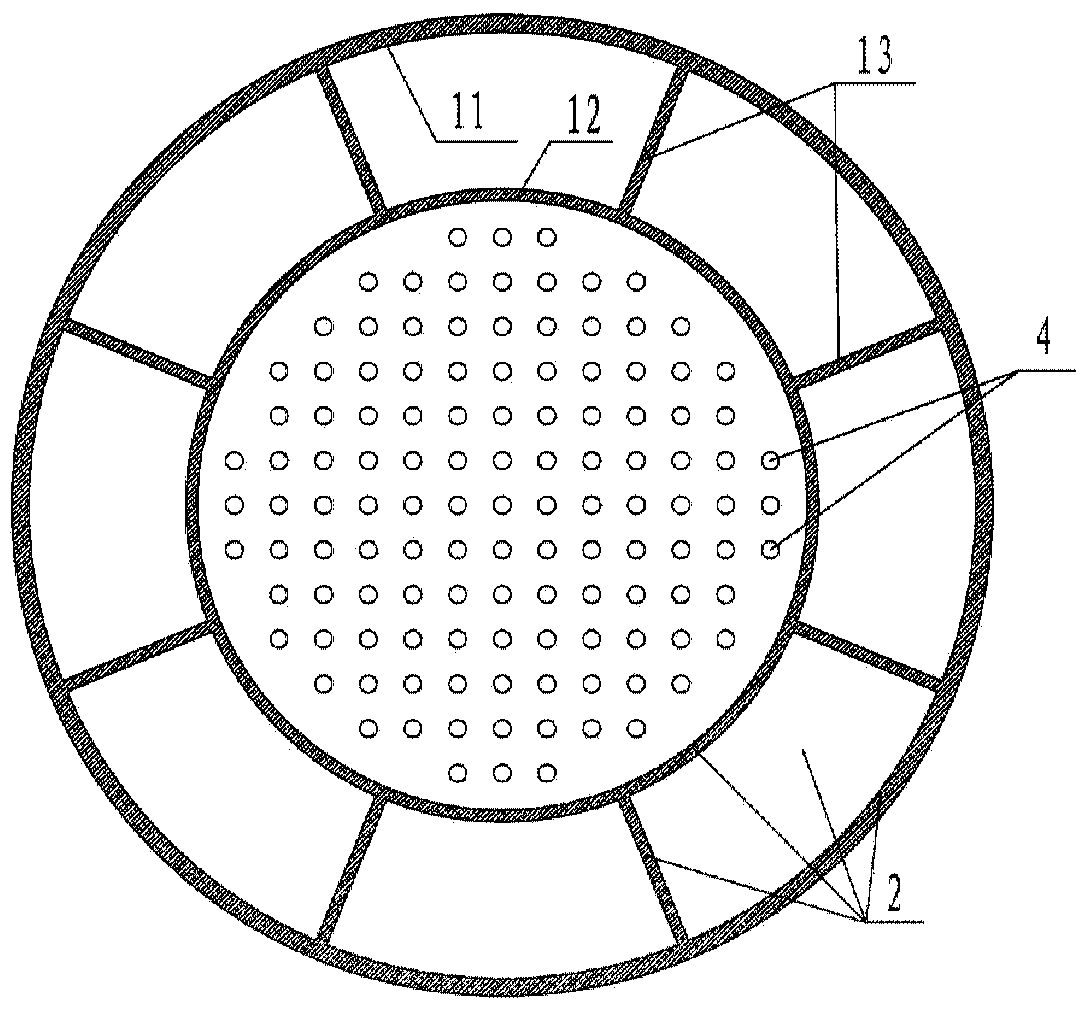

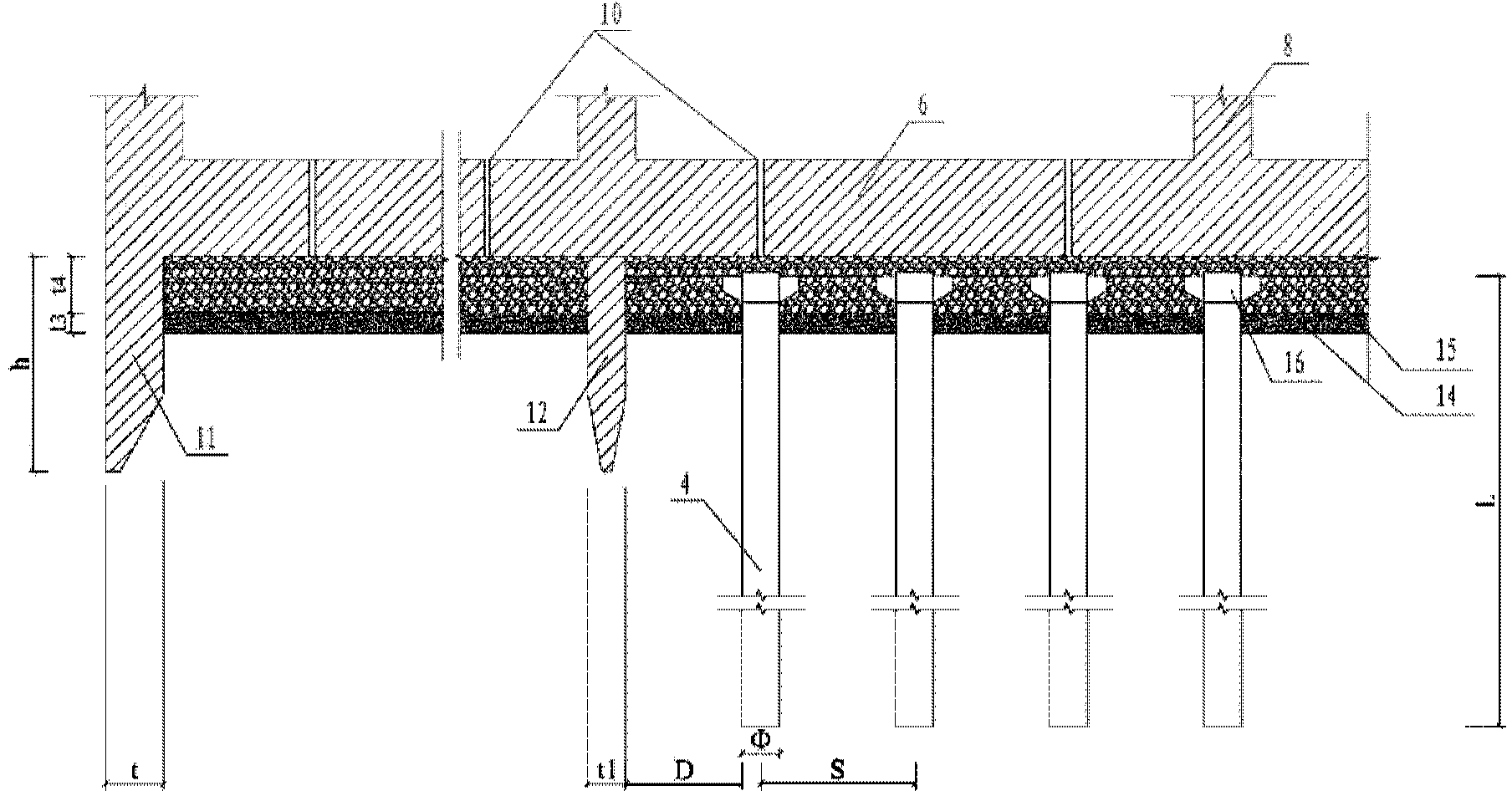

[0032] Such as figure 1 , figure 2 As shown, the present invention provides a caisson composite foundation with a suction skirt and semi-rigid connecting piles used in deep water and thick overburden foundations. The caisson composite foundation includes: a caisson 1, a suction skirt 2, a semi-rigid Rigid cushion 3 and prefabricated pile 4; among them, there are multiple suction skirts 2, the top of which is fixed to the bottom circumference of caisson 1; semi-rigid cushion 3 is formed under caisson 1 and directly contacts with the bottom of caisson 1 to become Integral; there are multiple prefabricated piles 4, the top of which is affixed to the inside of the semi-rigid cushion 3 and integrated with the semi-rigid cush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com