Rear-arranged main silencer

A technology of main muffler and rear end cover, which is applied in the direction of mufflers, machines/engines, engine components, etc. It can solve the problems that the exhaust pipe occupies the muffler volume and needs to be strengthened, so as to eliminate standing waves, reduce second-order noise, Effect of reducing low frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

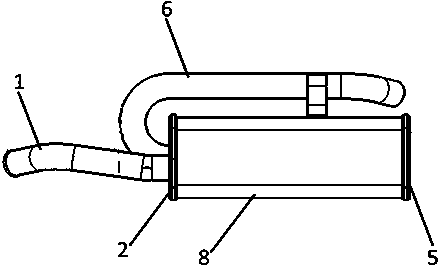

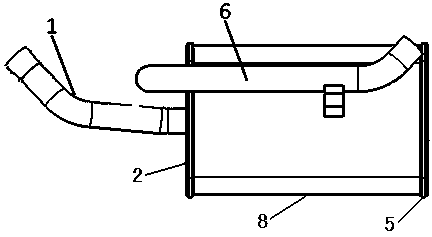

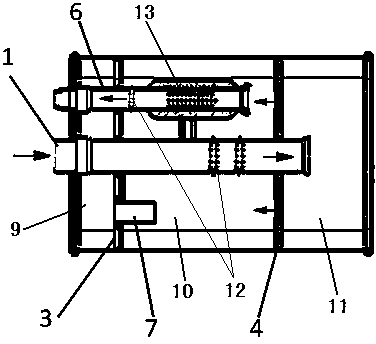

[0014] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] see Figure 1 to Figure 3 As shown, the rear main muffler includes a cylinder body 8 , an air inlet pipe 1 and an air outlet pipe 6 , and the two ends of the cylinder body 8 are sealed by the front end cover 2 and the rear end cover 5 . A first partition 3 and a second partition 4 are sequentially arranged inside the cylinder 8 along the longitudinal direction of the cylinder, dividing the cylinder into a first chamber 9 , a second chamber 10 and a third chamber 11 in sequence. The outlet end of the air inlet pipe 1 stretches into the third chamber 11 from the front end cover 2 of the cylinder body 8 , the first partition 3 , and the second partition 4 in turn, and the inlet pipe 1 located in the second chamber 10 There are two circles of ventilation holes 12 on the top. A plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com