Reciprocating type shaft seal sealing performance testing method and device

A technology of sealing performance and testing method, which can be used in liquid/vacuum measurement for liquid tightness, by measuring the acceleration and deceleration rate of the fluid, and by detecting the appearance of the fluid at the leak point, etc., which can solve the detection hysteresis and pertinence. Not strong and other problems, to achieve the effect of accurate results, simple and convenient operation, accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

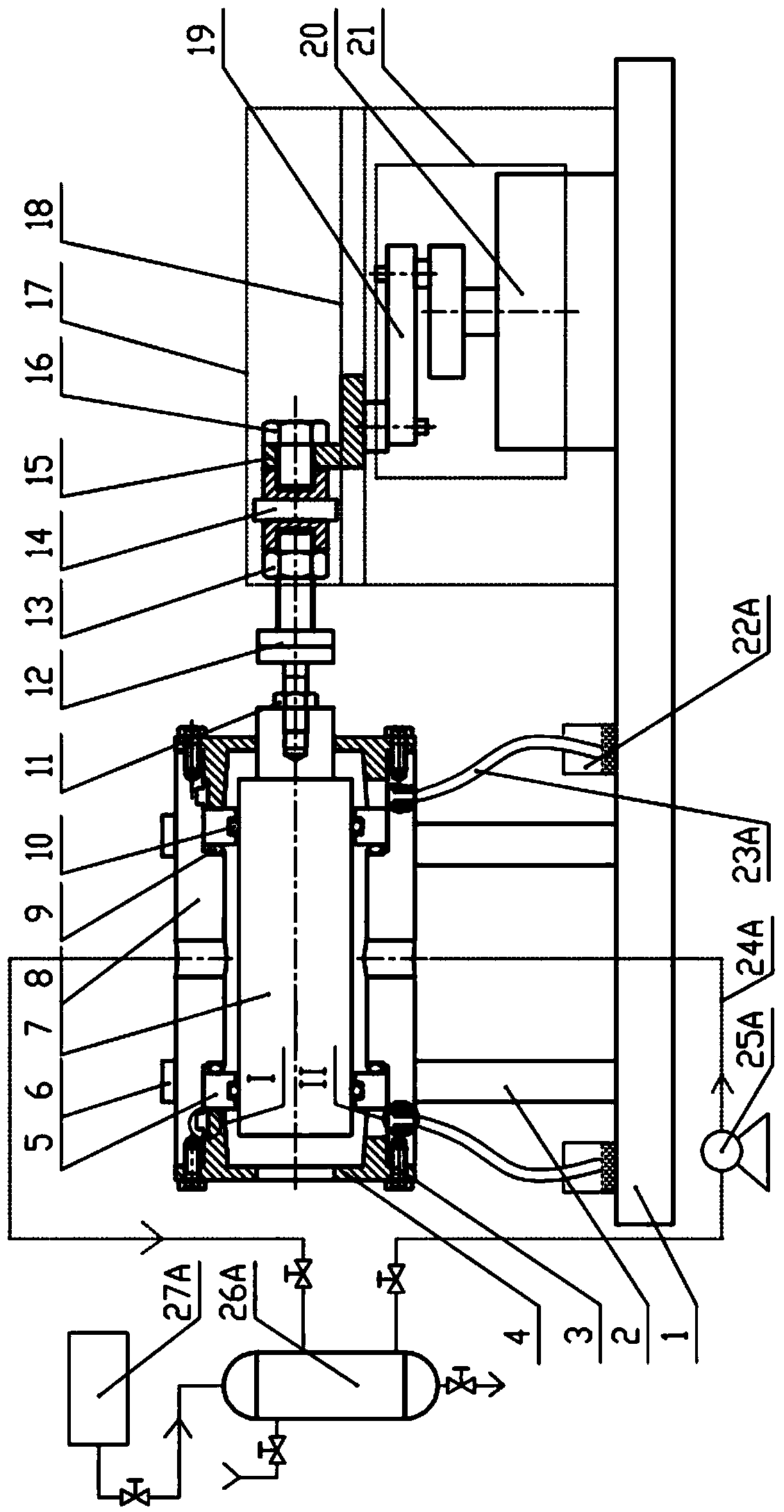

[0037] refer to Figure 1a , 1b , 1c, Figure 3a ~ Figure 3d , Figure 5a to Figure 6 , a test method for the sealing performance of a reciprocating shaft seal, said test method comprising the steps of:

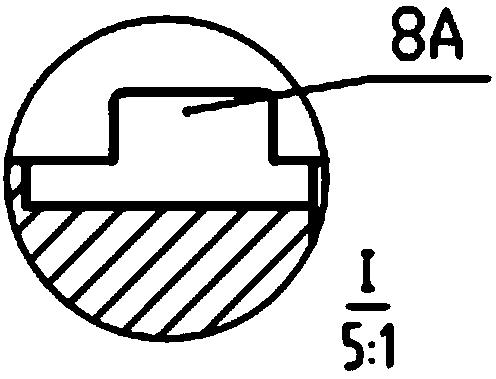

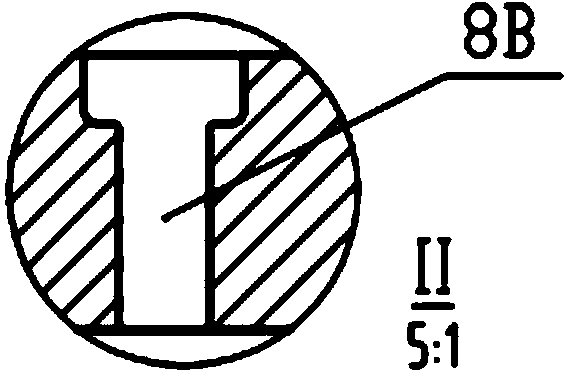

[0038]a. Install the sealing ring 9 on the sealing ring installation ring 5 with a groove, the sealing ring installation ring 5 is installed in the outer cylinder 8 and compressed by the end caps 4 at both ends of the outer cylinder 8; install the sealing ring in the outer cylinder 8 The main shaft 7 connects the sealed main shaft 7 with the tension and pressure sensor 14 through the coupling 12, and the tension and pressure sensor 14 is connected with the support block 15; the support block 15 moves along the slide rail 18 on the support block bracket 17, and the power is reciprocated horizontally The device 21 provides;

[0039] b. The data acquisition and control system controls the auxiliary device and the reciprocating horizontal motion device 21, so that the space be...

Embodiment 2

[0050] refer to figure 2 , Figure 4a ~ Figure 4d , Figure 5a to Figure 6 The difference between this embodiment and Embodiment 1 is that this embodiment is aimed at the pneumatic sealing test, and the detection device includes a suction gun 26B, an air guide tube 23B and a helium mass spectrometer leak detector 22B, and the air guide tube 23B One end is connected to the helium mass spectrometer leak detector 22B, and the other end communicates with the first opening on the outer cylinder 8; the auxiliary device includes a gas conduit 24B, a pressure regulator 25B and a helium cylinder 27B, and the suction The gun 26B is arranged on the open end of the helium cylinder 27B, one end of the gas conduit 24B communicates with the second opening on the outer cylinder, and the other end is connected to the pressure regulator 25B, the pressure regulator The device 25B is connected to the suction gun 26B; the second opening on the outer cylinder opposite to the other end of the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com