Flexible capacitive acceleration sensor and manufacturing method thereof

An acceleration sensor, flexible capacitor technology, applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, manufacturing microstructure devices, etc., can solve the problems of complex processing technology and structure, high manufacturing cost, and achieve low cost, simple process and structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

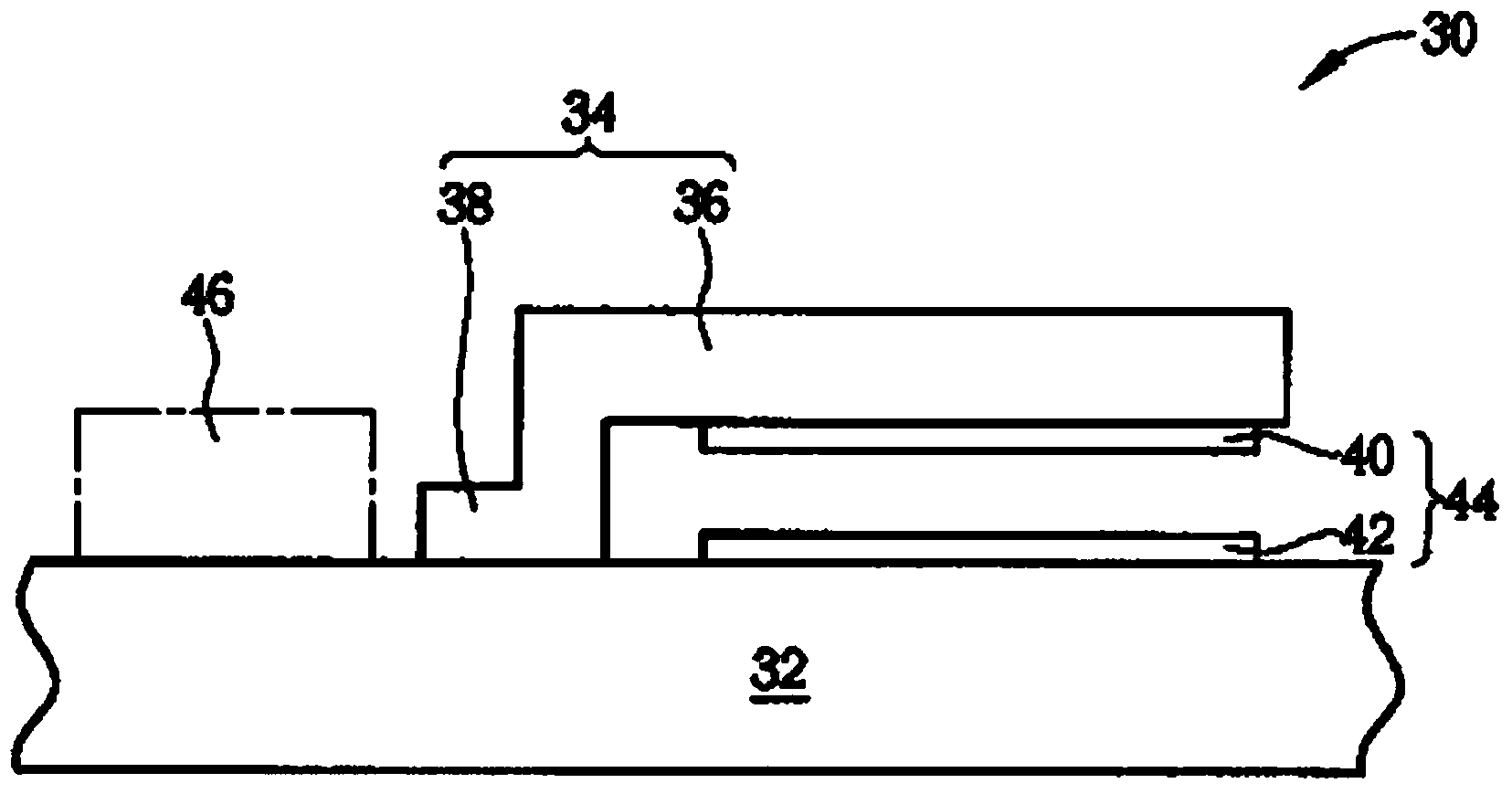

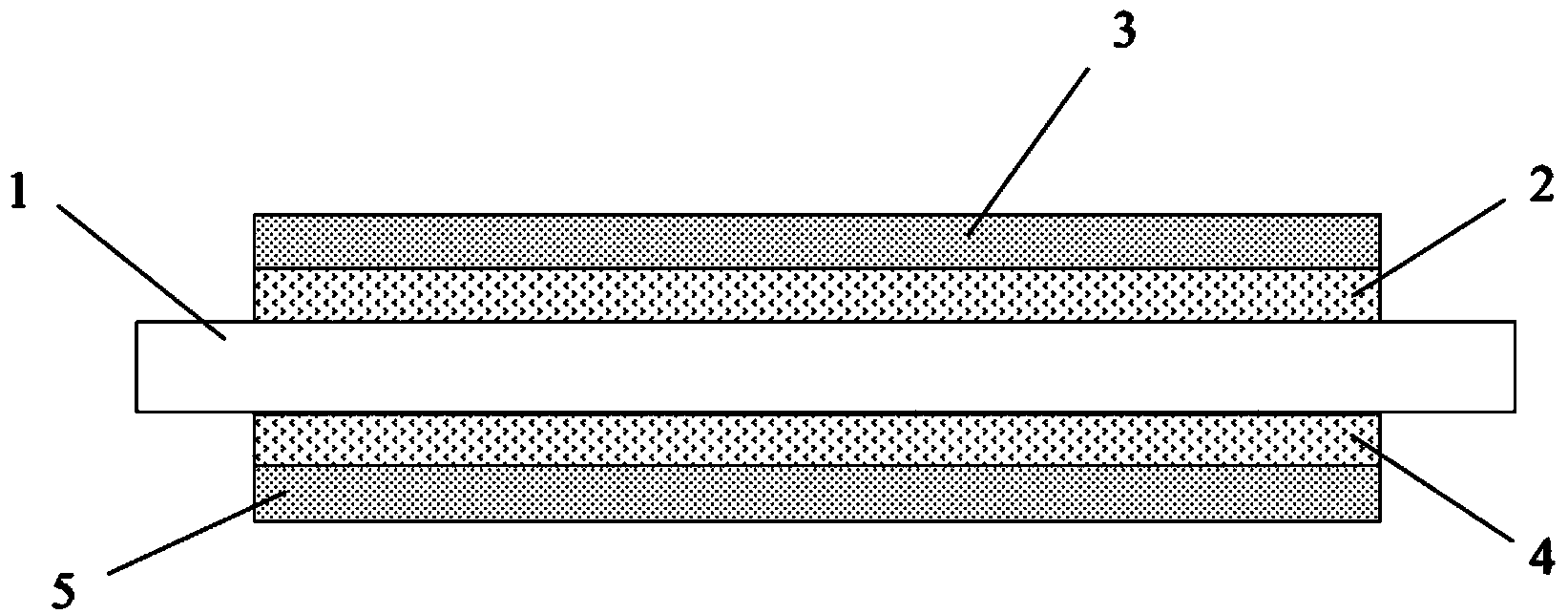

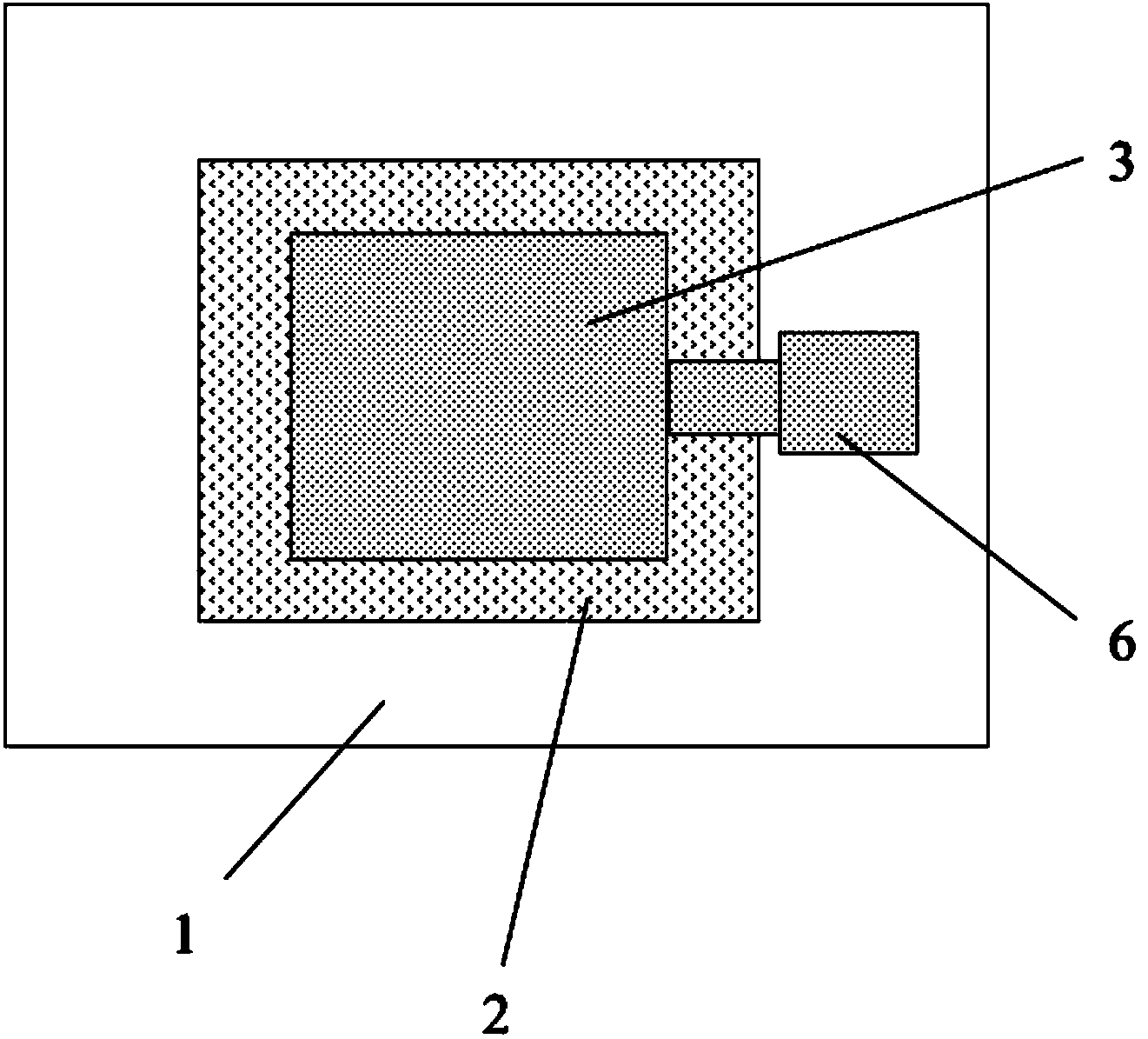

[0027] Please refer to figure 2 and image 3 , figure 2 It is a schematic cross-sectional view of the flexible capacitive acceleration sensor of the present invention, such as figure 2 As shown, the flexible substrate 1, the flexible substrate 1 is polyethylene terephthalate (PET, polyethylene terephthalate); the upper electrode 3, the upper electrode 3 is gold (Au) or copper (Cu) metal film, Set on the upper surface of the flexible substrate 1; the lower electrode 5, the lower electrode 5 is Au or Cu metal film, set on the lower surface of the flexible substrate 1; the connection layer, the connection layer is chromium (Cr) Or a titanium (Ti) metal thin film, which includes an upper connection layer 2 and a lower connection layer 4, the upper connection layer 2 is arranged between the flexible substrate 1 and the upper electrode 3 and connects the flexible substrate 1 and the upper electrode 3 , the lower connection layer 4 is disposed between the flexible substrate 1 a...

Embodiment 2

[0038] Please refer to figure 2 and image 3 , figure 2 It is a schematic cross-sectional view of the flexible capacitive acceleration sensor of the present invention, such as figure 2 As shown, the flexible substrate 1, the flexible substrate 1 is polyimide (PI, polyimide); the upper electrode 3, the upper electrode 3 is an Au or Cu metal film, and is arranged on the upper surface of the flexible substrate 1; The lower electrode 5, the lower electrode 5 is an Au or Cu metal film, which is located on the lower surface of the flexible substrate 1; the connection layer, the connection layer is a Cr or Ti metal film, which includes an upper connection layer 2 and a lower connection layer. layer 4, the upper connection layer 2 is arranged between the flexible substrate 1 and the upper electrode 3 and connects the flexible substrate 1 and the upper electrode 3, and the lower connection layer 4 is arranged between the flexible substrate 1 and the lower electrode 5 and connect ...

Embodiment 3

[0049] Please refer to figure 2 and image 3 , figure 2 It is a schematic cross-sectional view of the flexible capacitive acceleration sensor of the present invention, such as figure 2 Shown, flexible substrate 1, described flexible substrate 1 is polydimethylsiloxane (PDMS); Upper electrode 3, described upper electrode 3 is Au or Cu metal thin film, is arranged on the upper surface of described flexible substrate 1 ; the lower electrode 5, the lower electrode 5 is Au or Cu metal film, located on the lower surface of the flexible substrate 1; the connection layer, the connection layer is Cr or Ti metal film, which includes the upper connection layer 2 and the lower A connection layer 4, the upper connection layer 2 is arranged between the flexible substrate 1 and the upper electrode 3 and connects the flexible substrate 1 and the upper electrode 3, and the lower connection layer 4 is arranged between the flexible substrate 1 and the lower electrode 3. The flexible substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com