Terahertz wave detector and manufacturing method thereof

A detector and terahertz technology, applied in the field of metamaterials and terahertz detection, can solve the problem of low absorption rate of terahertz waves, and achieve the effect of enhancing the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

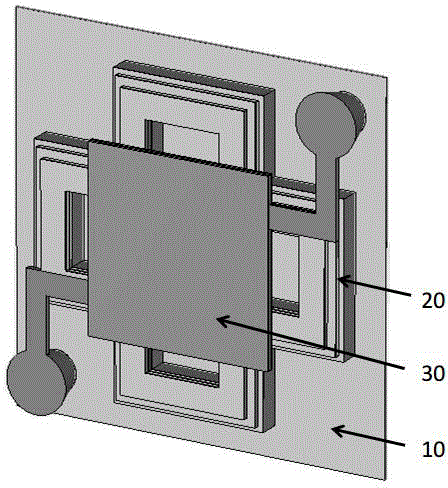

[0044] The embodiments of the present invention solve the technical problem of the low absorption rate of terahertz waves by the terahertz wave detector in the prior art by providing a terahertz wave detector and a preparation method thereof, thereby achieving the ability to detect terahertz waves in a specific terahertz range. High absorption can be achieved and the absorption can be converted into electrical signals, providing the basis for terahertz imaging detection.

[0045] In order to solve the above-mentioned technical problem of low absorption rate of terahertz waves by existing terahertz detectors, the general idea is as follows:

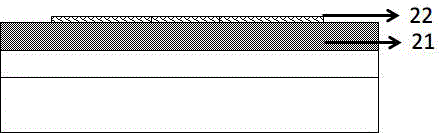

[0046] The terahertz wave detector used includes a top sensitive layer and a metamaterial metal hollow cross absorption layer located under the top sensitive layer. Since the absorption layer adopts the metal hollow cross structure of metamaterials, it is a center-symmetric structure, which can eliminate the device interference. The anisot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com