Shockproof thermoplastic helmet liner and manufacturing method thereof

A production method and thermoplastic technology, applied to helmets, chemical instruments and methods, helmet caps, etc., can solve the problems of difficult helmet padding, high hardness, poor stability, etc., and achieve stable and comfortable wearing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

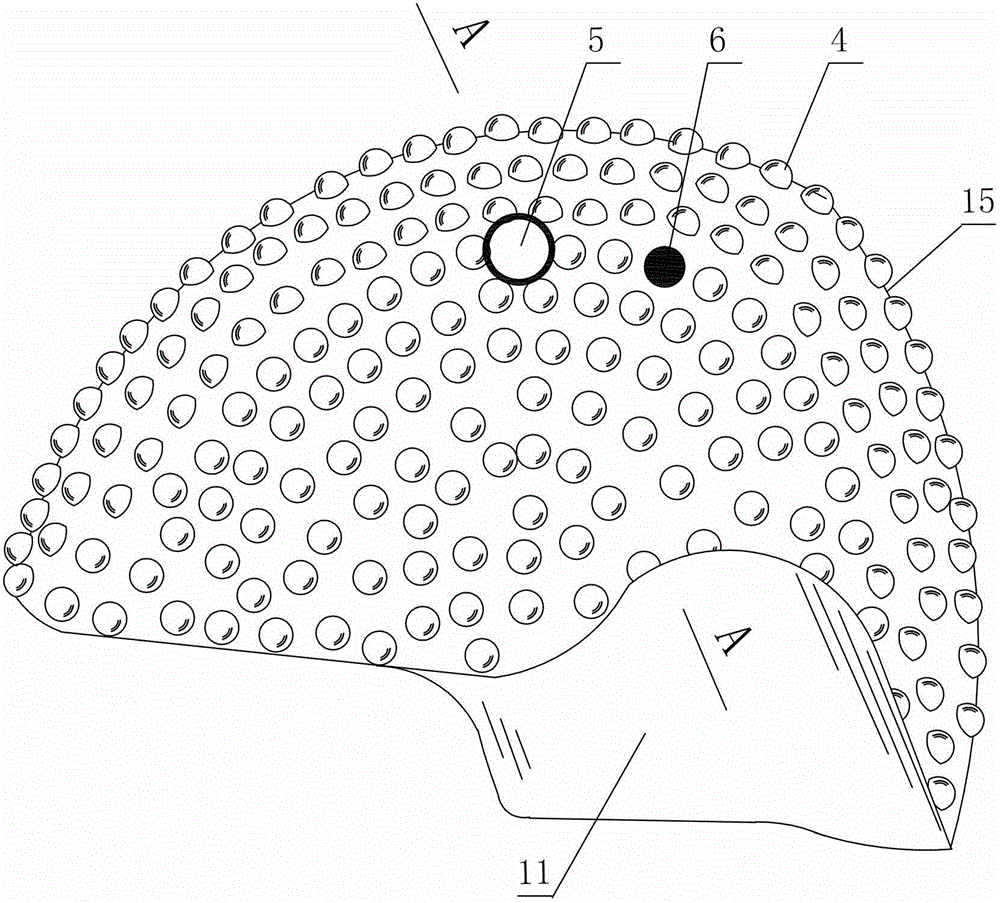

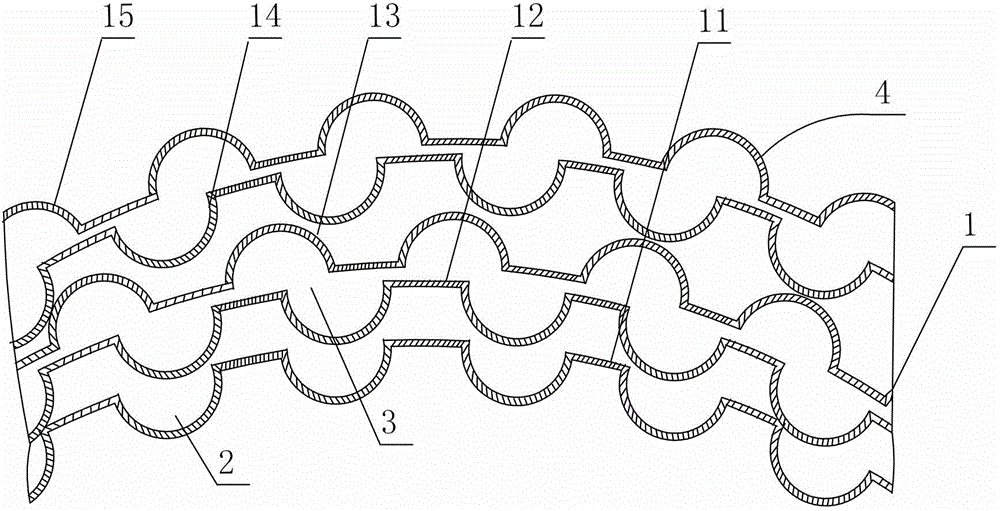

[0034] A kind like figure 1 , figure 2 The helmet shockproof thermoplastic liner (TPL liner) of the present invention is shown. The helmet shockproof thermoplastic liner is formed by superimposing five layers of sheets 1 processed into the shape of the head. Each layer of sheet 1 is provided with an array of rows. The hemispherical cavity 2 of the cloth (from the other side is the hemispherical hollow protrusion 4), the hemispherical cavity 2 is an open (open) cavity, and the hemispherical cavity 2 of the adjacent two layers of sheets 1 is pressed They are nested, butted or interlocked in substantially the same direction; the middle of the helmet shock-proof thermoplastic liner contains array-like spherical hollow bodies 3, which are composed of two adjacent hemispheres of sheets 1 The cavities 2 are formed by butting each other. The top of the shockproof thermoplastic liner of the helmet is provided with an exhaust hole 5.

[0035] For specific structure, see figure 2 In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com