An adsorption double-tower drying device

A drying device and adsorption technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of hidden dangers in the use and maintenance of connecting pipelines, safety guarantees, inability to complete replacement independently, and unfavorable structural compactness. To achieve the effect of compact structure, ingenious structure and easy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

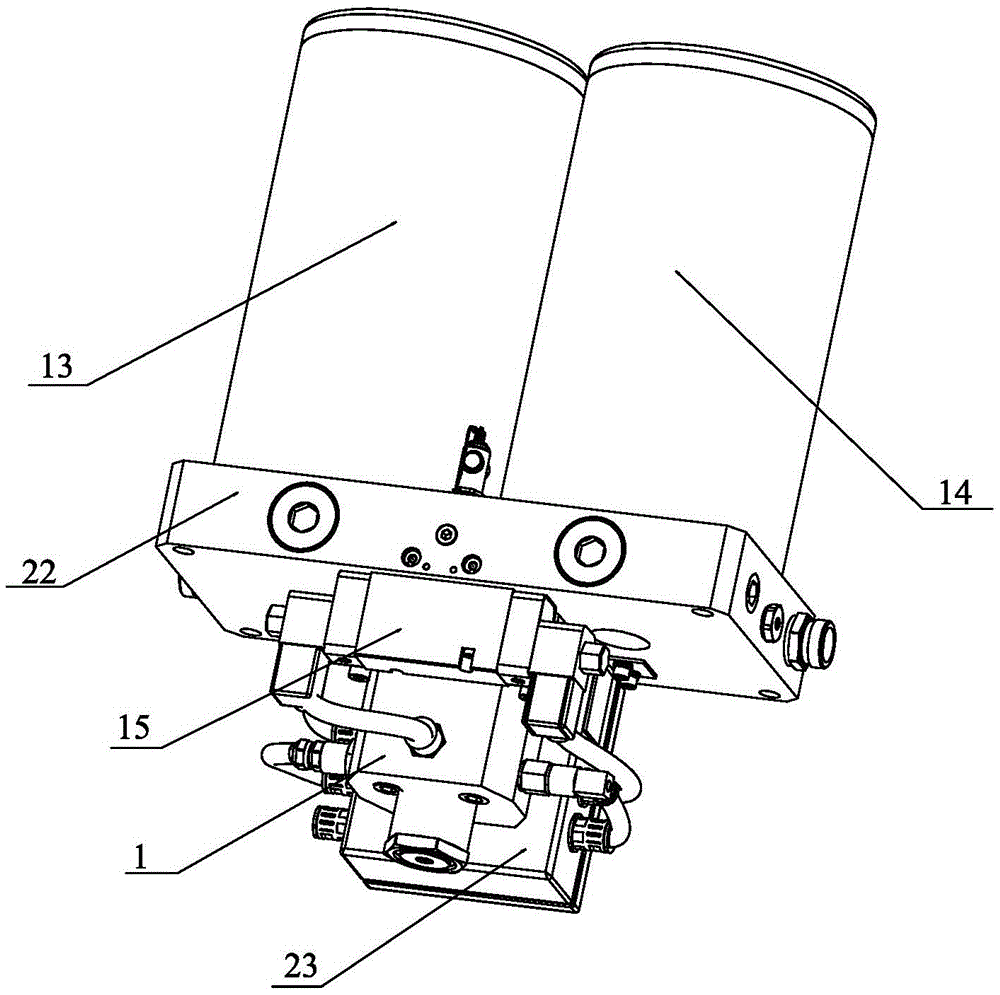

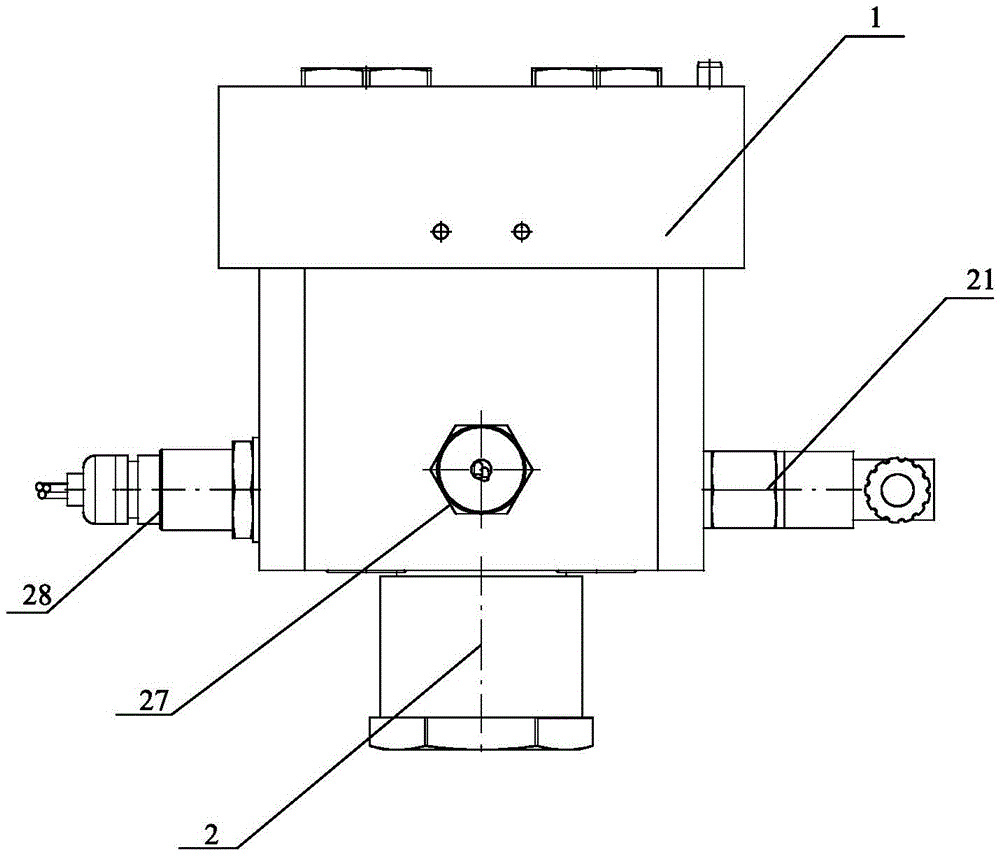

[0030] Such as figure 1 , The adsorption double-tower drying device consists of: the first drying tower 13, the second drying tower 14, the solenoid valve 15, the reversing valve 1, the integrated gas circuit board 22, and the electric controller 23.

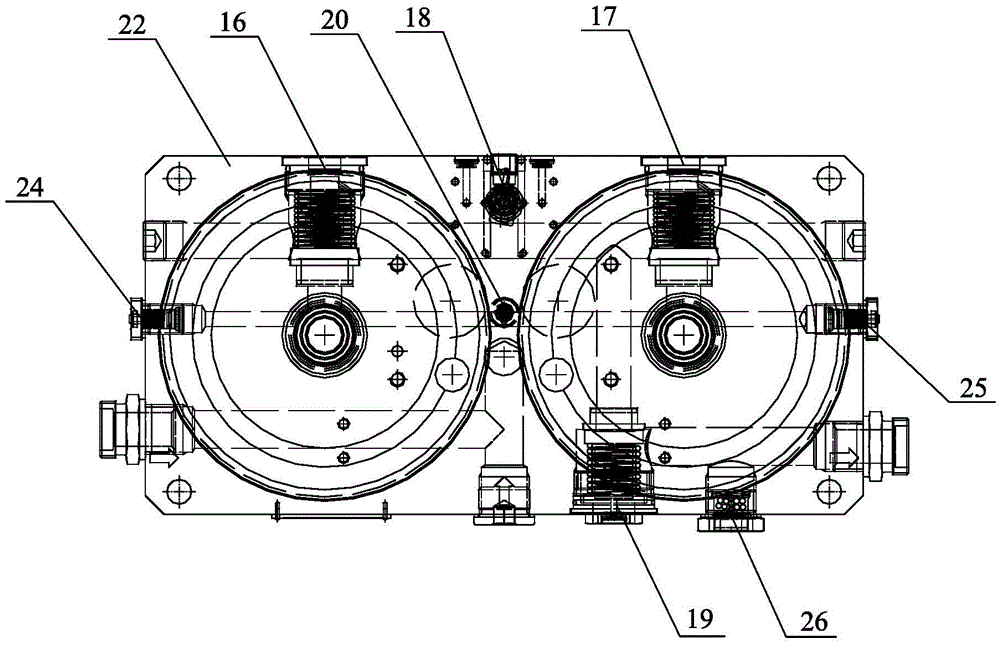

[0031] Such as figure 1 , figure 2 As shown, the integrated air circuit board is fixed with the first drying tower 13, the second drying tower 14, the solenoid valve 15, the reversing valve 1, the electric controller 23, the first one-way valve 16, 17-the second one-way valve 17. Throttle valve 20, minimum pressure valve 19, test joint 18, first pressure indicator 24, second pressure indicator 25, humidity in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com