A high-precision robot grinding system and its control method

A robot and high-precision technology, which is applied in the direction of automatic grinding control devices, program-controlled manipulators, manipulators, etc., can solve problems such as low degree of automation, shortage of skilled operators, and no solutions, so as to improve debugging time and enhance operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

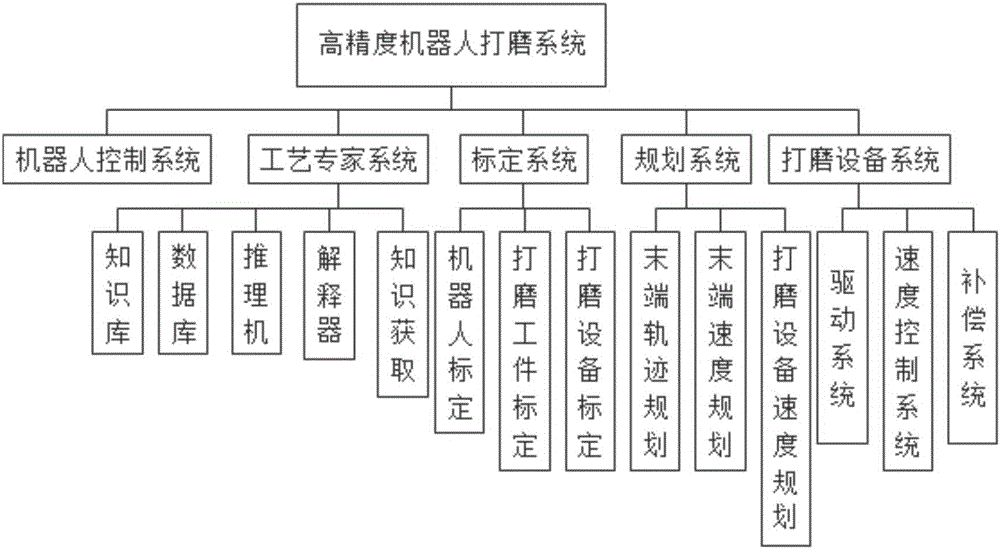

[0040] Figure 1 It is a composition diagram of the high-precision robot grinding system. The system manages the various process parameters involved in the grinding process in the database by introducing an expert system, and can input and explain the user input through the human-computer interaction interface, and then perform data reasoning to obtain effective data output. For different types of workpieces, reliable and high-quality acquisition of grinding process parameters, and then sent to the calibration and planning system. The calibration system is composed of robot calibration system, workpiece calibration system and grinding equipment calibration system. Among them, the robot calibration system completes the calibration of robot kinematics parameters and robot dynamics parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com