Group joint debugging method of large-scale dry process cement decentralized control system

A decentralized control system and joint debugging technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of low work efficiency, increased debugging workload, surge in manpower and time costs, and improve work efficiency. , The effect of reducing workload and shortening debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

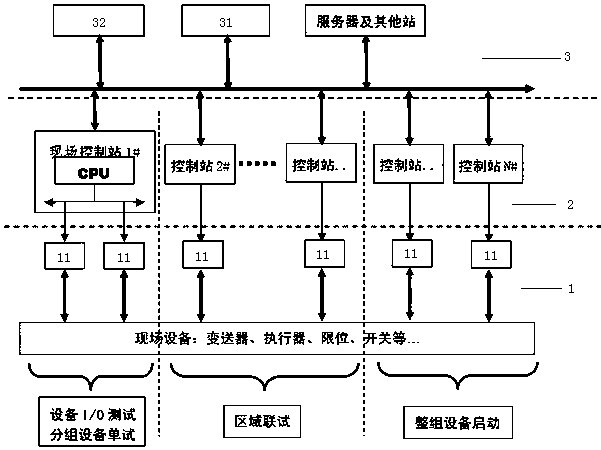

[0047] Such as figure 1 Shown: a large-scale dry cement decentralized control system group joint debugging method, characterized in that it includes the following steps:

[0048] Step 1: Partitioning and grouping

[0049] According to the cement production process and the regional distribution of equipment, the main control stations such as raw material allocation, raw meal mill, coal pulverization, firing kiln, cement mill, slag mill, cement allocation, finished product warehouse, and cement packaging will generally be arranged on site. Overall, it can be divided into three areas:

[0050] 1) Limestone storage yard, raw material allocation, and raw meal mill are one area, and its raw meal homogenization warehouse is a buffer zone for process connection;

[0051] 2) Coal powder mill, firing kiln, cement mill, and slag mill are one area, and its cement clinker warehouse is a buffer zone for process connection;

[0052] 3) Cement blending, finished product warehouse, and ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com