Method for improving non-sugar solid content of fruity yellow wine

A technology of non-sugar solids and rice wine, which is applied in the field of increasing the content of non-sugar solids in fruity rice wine, which can solve the problem of insufficient color, aroma and overall coordination of wine quality, low content of non-sugar solids in raw wine, and low content of dry extracts in raw wine and other problems, to achieve the effect of solving product homogeneity, improving taste, and ensuring thorough fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

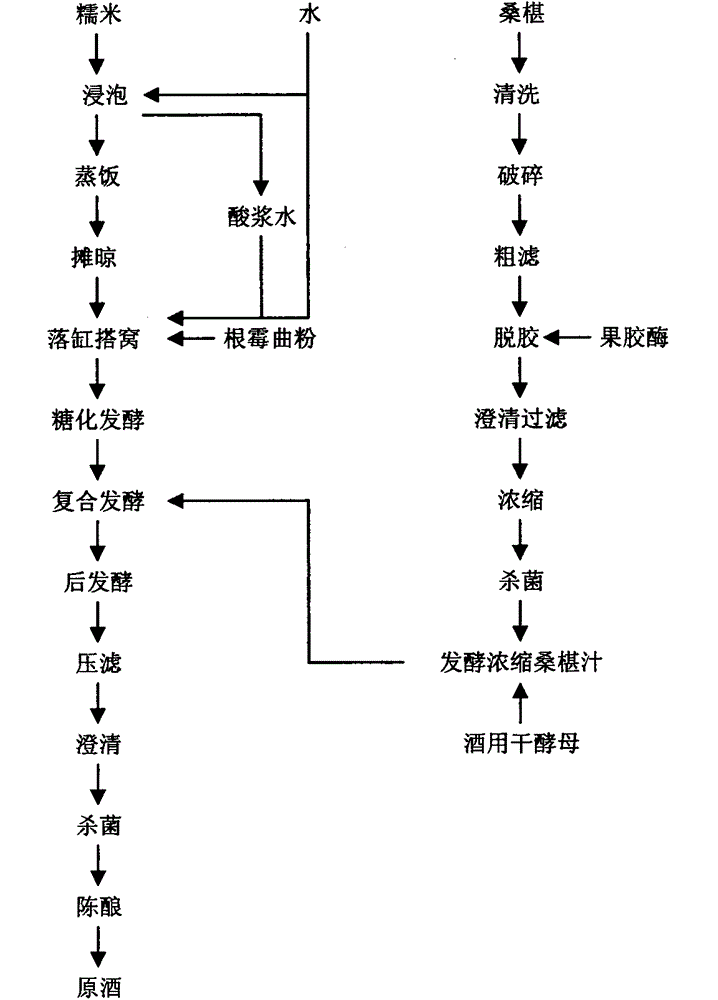

[0016] Implementation case 1: (mulberry glutinous rice wine)

[0017] (1) Raw material formula: 100kg of glutinous rice, 600kg of mulberries, 500g of pure rhizopus koji powder, 300g of dry yeast for wine, 600g of pectinase.

[0018] (2) Process flow (see figure 1 : Example -- mulberry glutinous rice wine production process flow chart)

[0019] (3) Production method

[0020] 1. Wash 100kg of glutinous rice that has been whitened and stacked naturally for a week, soak the rice for 24-48 hours, take it out, drain the water and cook it. The output of 100kg of glutinous rice is about 180kg. After fermentation, it becomes Physalis water with an acidity of 0.39-0.5%. After sterilization, it is used to adjust the acidity of the mash during the saccharification and fermentation of glutinous rice. The steamed rice is spread out and cooled to 32-35°C, poured into a fermenter, and 24kg of Physalis Mix rice with water and 16kg of clear water, spread 500g of pure Rhizopus koji powder, bu...

Embodiment example 2

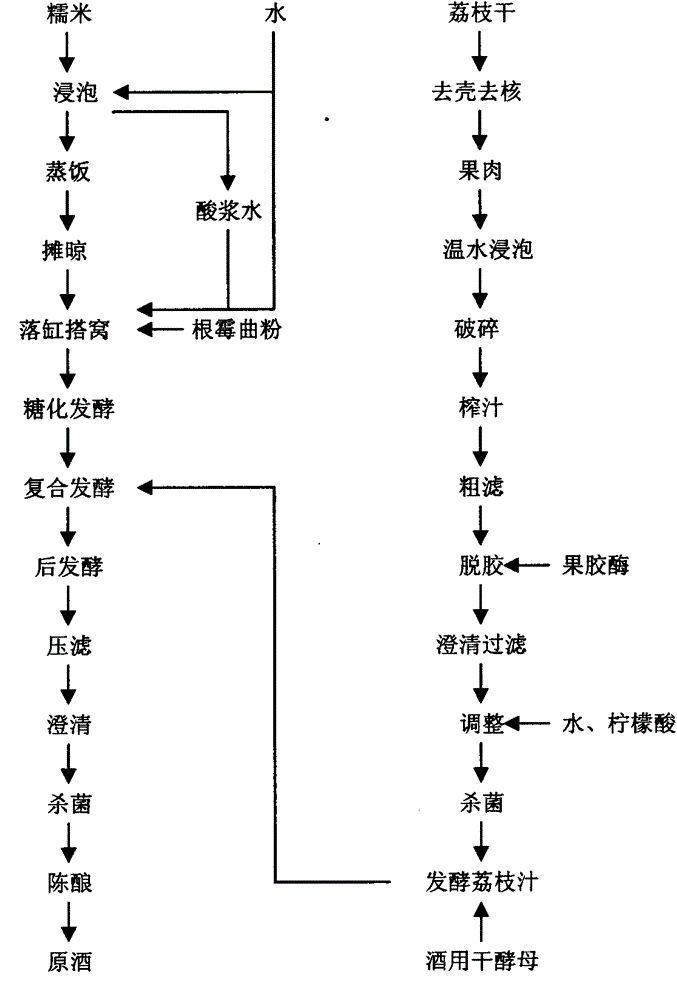

[0023] Implementation case 2: (lychee glutinous rice wine)

[0024] (1) Raw material formula: 150kg of glutinous rice, 170kg of dried litchi, 750g of pure rhizopus koji powder, 250g of dry yeast for wine, 300g of pectinase, and an appropriate amount of citric acid.

[0025] (2) Process flow (see figure 2 : Example -- production process flow chart of lychee glutinous rice wine)

[0026] (3) Production method

[0027]1. Wash 150kg glutinous rice that has been whitened and stacked naturally for a week, soak the rice for 24-48 hours, take it out, drain the water and cook it. The output of 150kg glutinous rice is about 270kg. After fermentation, it becomes Physalis water with an acidity of 0.39-0.5%. After sterilization, it is used to adjust the acidity of the mash during the saccharification and fermentation of glutinous rice. The steamed rice is spread out and cooled to 32-35°C, poured into a fermenter, and mixed with 36kg of Physalis Mix rice with water and 24kg of clear wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com