Method for recycling nitric acid deplating waste liquid of clamp for copper line electroplating in PCB plant and complete equipment

A technology for stripping waste liquid and electroplating copper, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of difficult cost control, complicated operation and high cost, and achieve the effects of simple structure, high economic value and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe in detail the structural features, technical means, and achieved goals and effects of the present invention, the following will be described in detail in conjunction with the implementation and accompanying drawings.

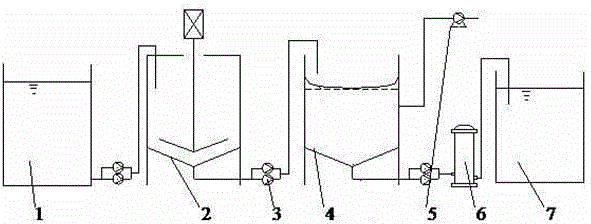

[0014] Such as figure 1 As shown, a complete set of regeneration equipment for nitric acid deplating waste liquid includes a waste liquid collection tank 1, a reaction kettle 2, a suction filtration tank 4, a precision filter 6, a regeneration liquid storage tank 7, a pump 3 and a vacuum pump group 5, It is characterized in that the waste liquid collection tank 1 is connected to the reactor 2 through the pump 3 and the pipeline, the reactor 2 is connected to the suction filtration tank 4 through the pump 3 and the pipeline, and the bottom of the suction filtration tank 4 is connected to the precision filter through the pump 3 and the pipeline 6. The liquid outlet of the precision filter 6 is connected to the regeneration liquid storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com