Control method and control system for water feed pump turbine

A technology for feeding water pump steam turbines and control methods, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., and can solve problems such as rising exhaust pressure of small steam turbines and failure of output of small steam turbines to meet requirements, so as to achieve simple operation process and easy solution The effect of increasing the back pressure of the condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only for demonstration and explanation, and does not limit the present invention in any form.

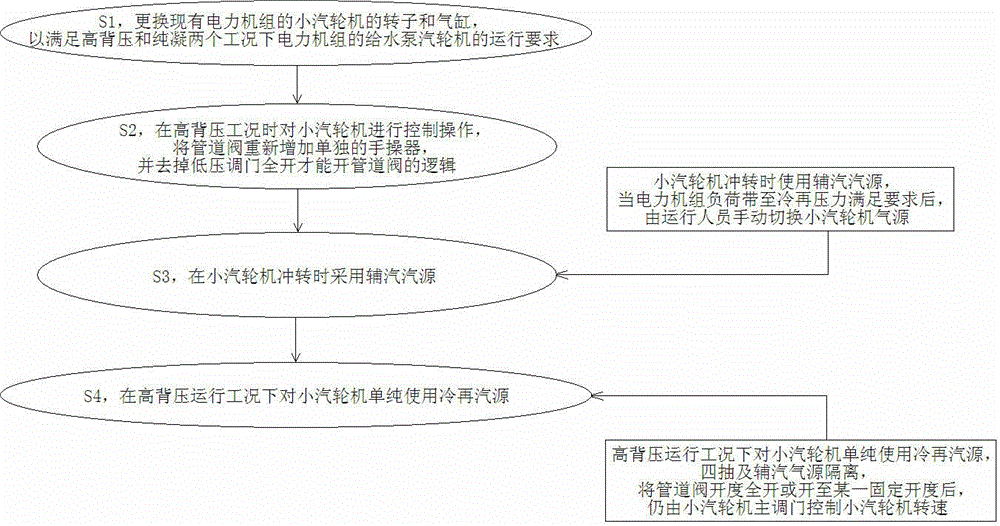

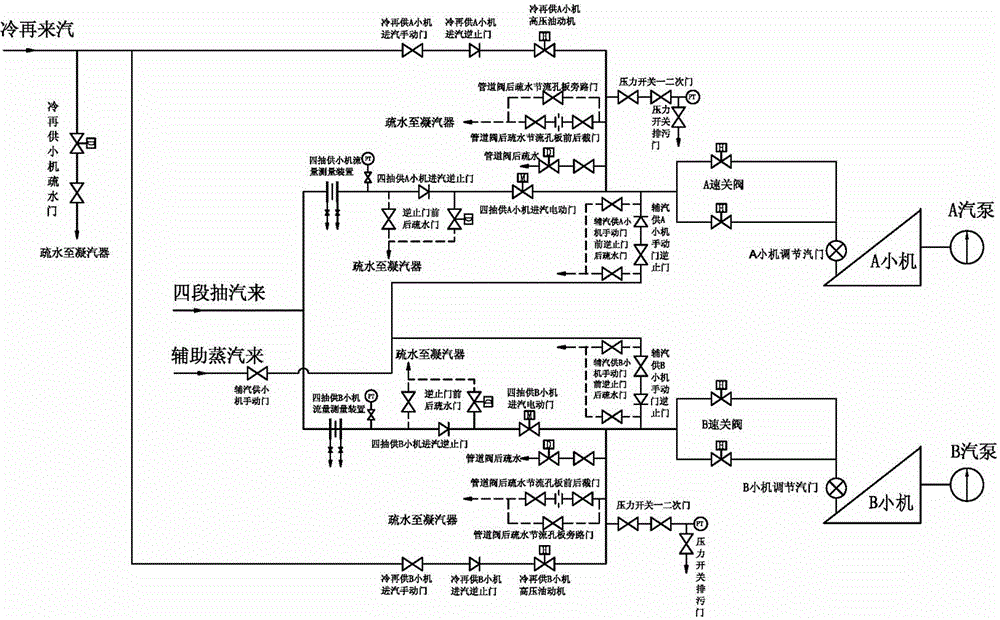

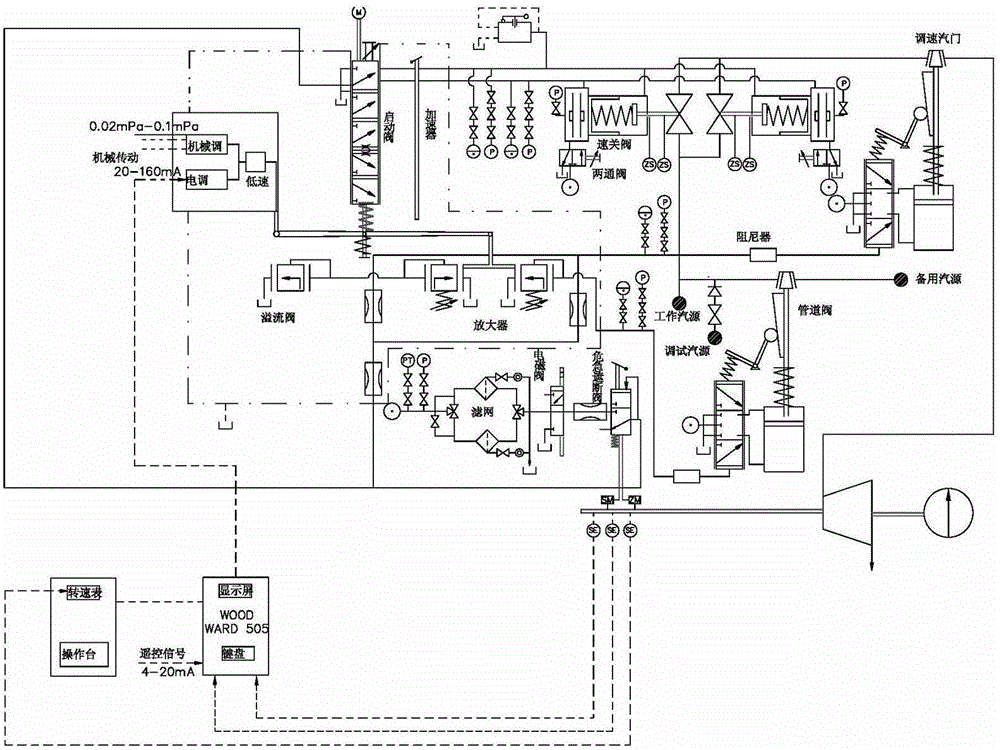

[0031] In order to realize the safety and economy of feedwater pump steam turbine operation under the premise of thermal process in heating period and non-heating period, the cold recovery is used as the steam source of small machine in the heating period (that is, high back pressure condition), and the non-heating period (i.e. pure condensing condition) use four pumps as the steam source of the small machine, such as figure 1 As shown, the operation method of the feedwater pump steam turbine suitable for heating and pure condensing dual mode includes the following steps: S1, replace the rotor and cylinder of the small steam turbine of the existing power unit to meet the two requirements of high back pressure and pure cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com