Direct type backlight module with light bars located on back side of backboard

A backlight module, direct-type technology, applied in the field of direct-type backlight modules, can solve the problems that the reflective sheet and the back plate cannot be well fitted, the assembly process of the backlight module is very demanding, and the reflective sheet is warped, etc. Achieve the effect of improving after-sales maintenance efficiency, reducing R&D costs, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

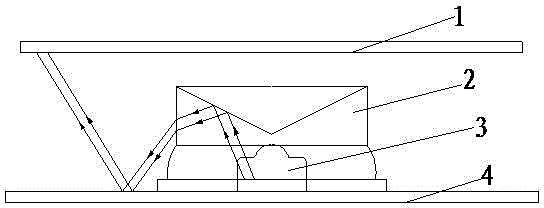

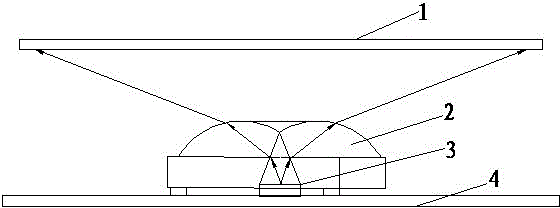

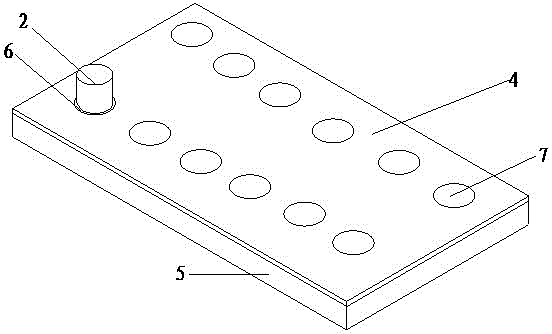

[0030] Direct-lit backlight modules include reflective and refractive backlight modules, such as figure 1 As shown, the main working principle of the reflective lens is that the light is emitted from the LED 3 , passes through the lens 2 and hits the reflective sheet 4 below, and then reflects to the diffuser plate 1 above; figure 2 As shown, the working principle of the refracting lens is that the light emitted from the LED 3 is refracted by the lens 2 and directly hits the diffuser plate 1 above. Therefore, it can be seen that the backlight module has high requirements on the flatness of the reflection sheet 4. If the assembly of the reflection sheet 4 is not flat enough, it will seriously affect the direction of light irradiation, making the brightness of the backlight module uneven, and some places are too bright and some places are too bright. dark situation. Moreover, a small change in the local position of the reflective sheet 4 will change the direction of light irra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com