Built-in self-pre-tightening hanging piece of heat exchange tube

A heat exchange tube and built-in technology, which is applied in the field of heat exchange tube built-in self-pretensioning pendants, can solve the problems of pendants easy to fall off and fall down, and insufficient pretightening force, so as to increase working stability and service life, and prevent falling out and lodging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

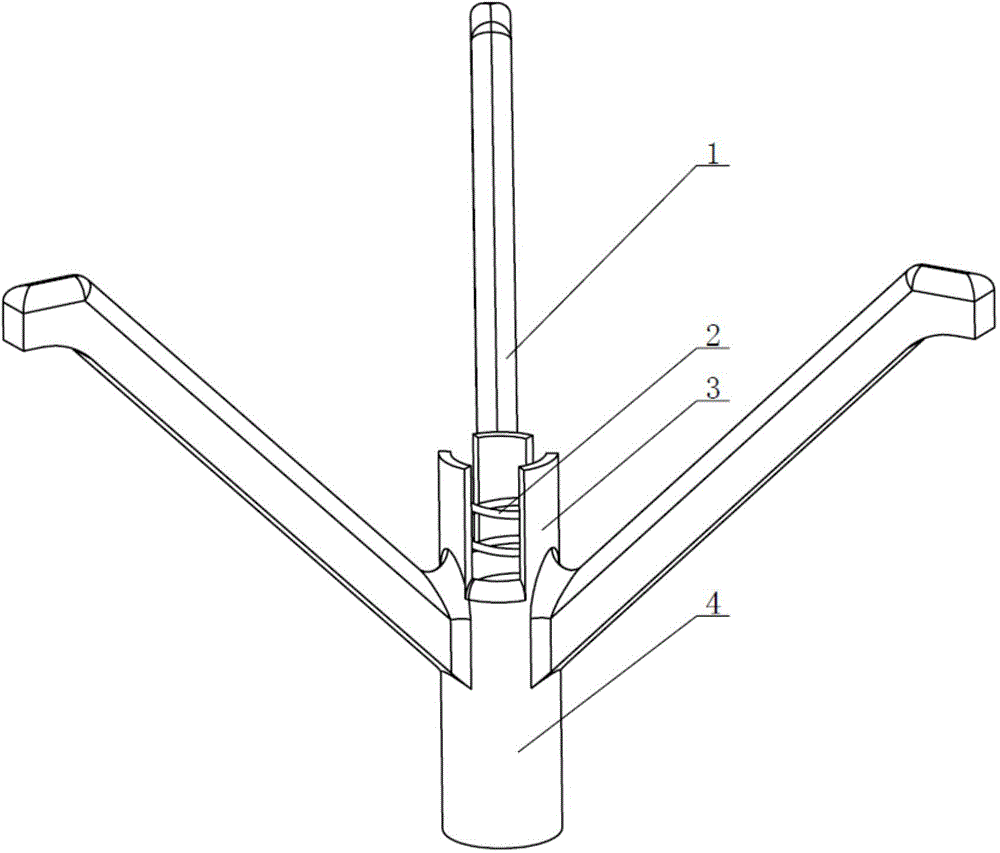

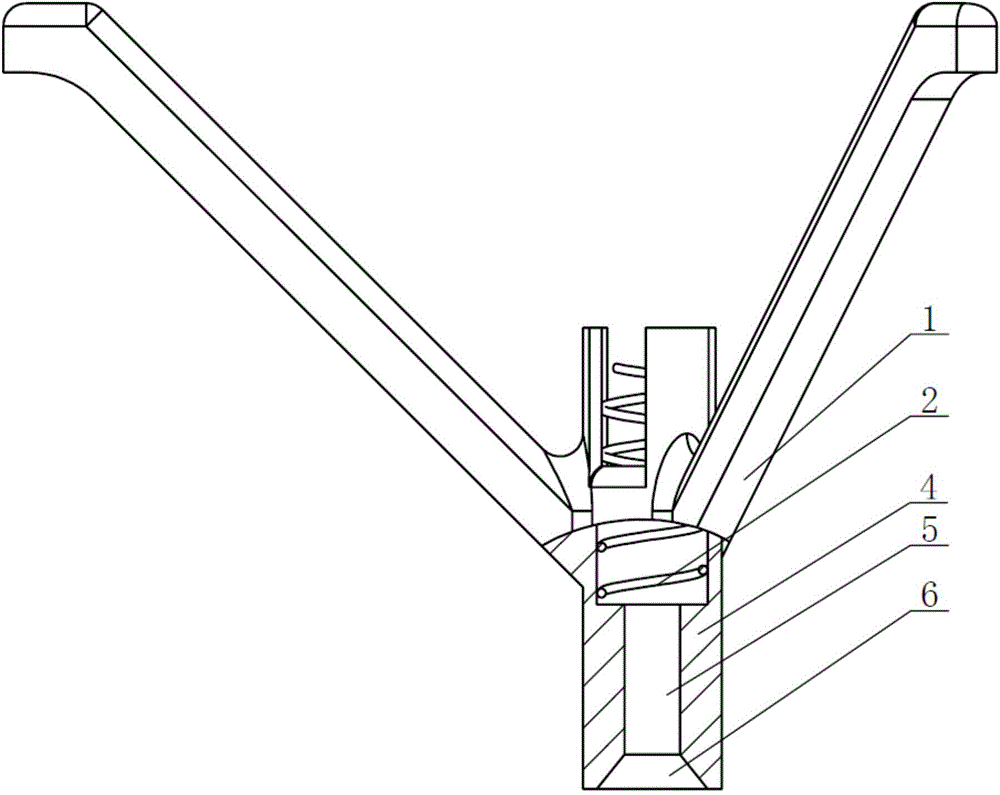

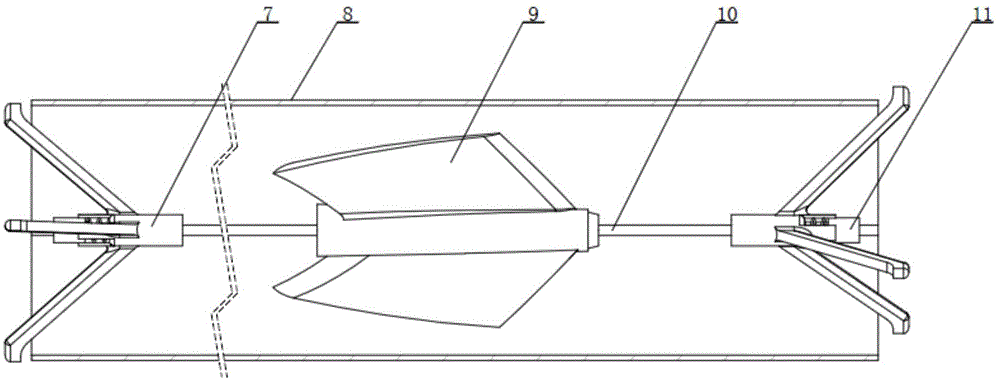

[0014] Such as image 3 Shown is a specific embodiment of the self-locking pendant that can be assembled: the whole set mainly includes the heat exchange tube 8, the flexible shaft 10, the rotor 9 and the heat exchange tube built-in self-tightening pendant 7 of the present invention. When installing the device, give the pre-tightening spring 2 an axial pressure to compress it under force. Tighten the flexible shaft 10 and install the limiter 11. After the installation is completed, remove the pressure of the pre-tension spring 2, and the pre-tension spring 2 will stretch to give the limiter 11 an axial force, thereby increasing the flexible shaft 10 of the device. The pre-tightening force prevents the wear of the rotor 9 on the flexible shaft 10 to the heat exchange tube 8 due to the too small pre-tightening force of the flexible shaft 10, and the reduction of the enhanced heat transfer effect of the device due to the increase in the rotation resistance of the rotor 9. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com