Method and system for dynamic measurement of liquid surface morphology and dosage of liquid propellant in storage tank

A technology for liquid and dynamic measurement of storage tanks, applied in the direction of measuring devices, instruments, etc., to achieve the effects of improving measurement accuracy and sensitivity, reducing equipment, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

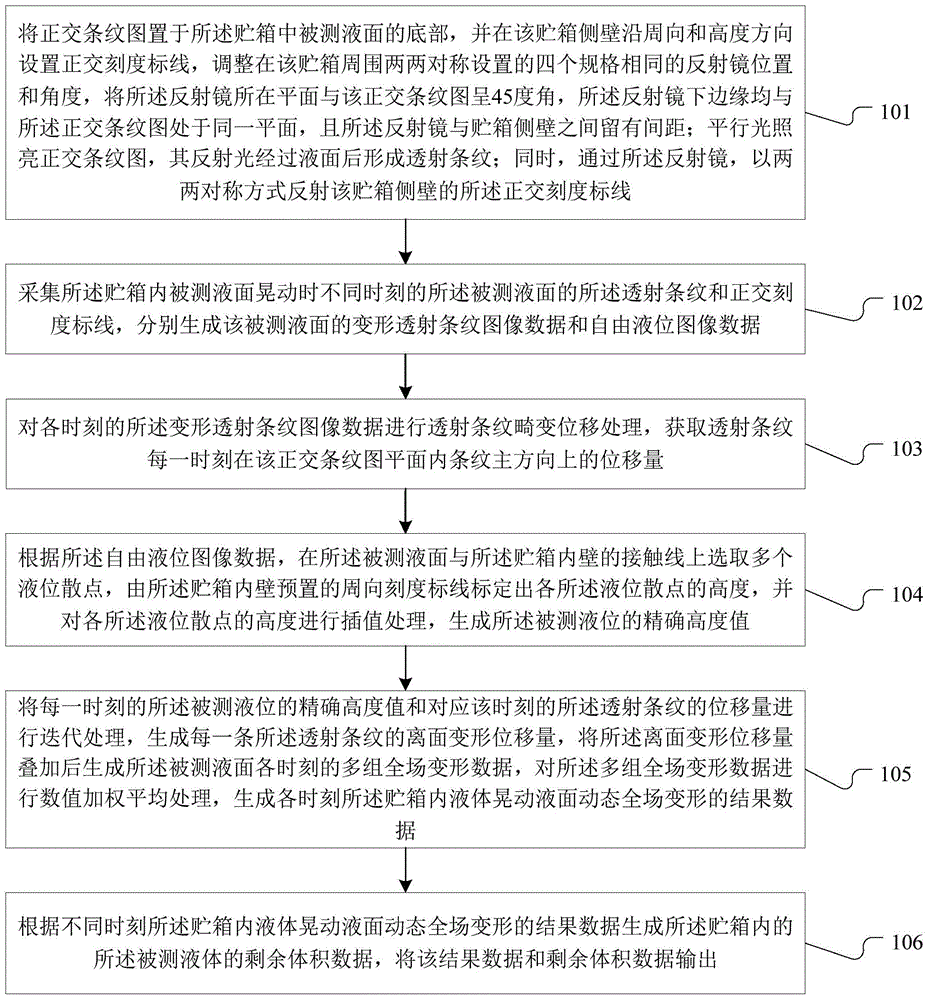

[0047] Such as figure 1 As shown, it is a process flow of a liquid propellant liquid surface profile and dosage dynamic measurement method for a storage tank described in Embodiment 1 of the present application.

[0048] Step 101, place the orthogonal fringe pattern at the bottom of the measured liquid level in the storage tank, and set orthogonal scale markings on the side wall of the storage tank along the circumferential and height directions, and arrange four specifications symmetrically around the storage tank. For the same reflector, adjust the position and angle of the reflector, the plane where the reflector is located is at an angle of 45 degrees to the orthogonal fringe pattern, the lower edge of the reflector is on the same plane as the orthogonal fringe pattern, and the There is a distance between the reflector and the side wall of the storage tank; the parallel light illuminates the orthogonal fringe pattern, and the reflected light forms transmission stripes afte...

Embodiment 2

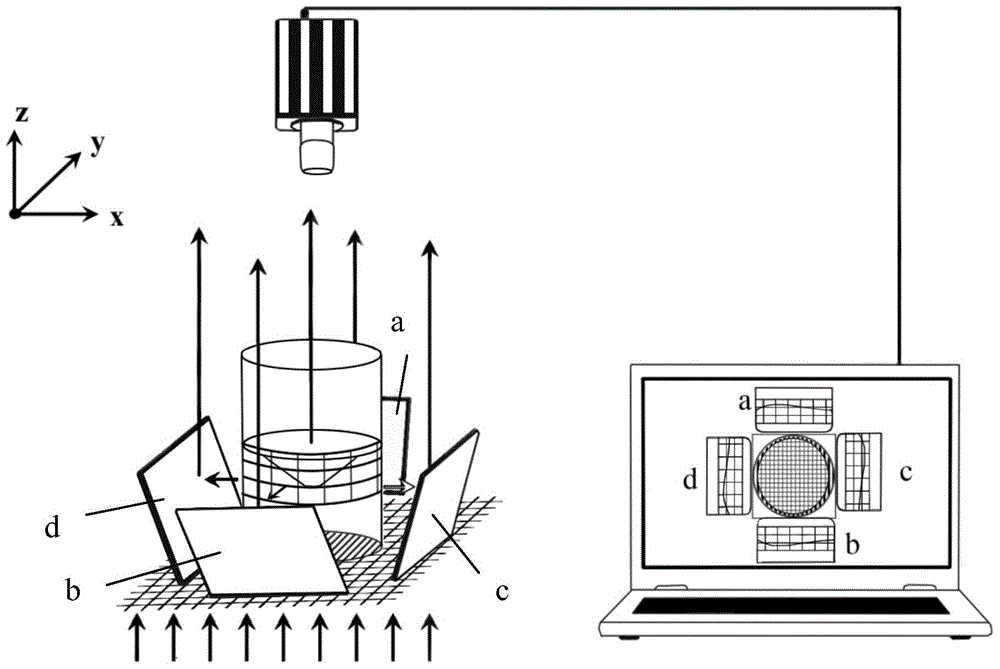

[0061] For the tank liquid propellant liquid surface morphology and dosage dynamic measurement method described in the first embodiment, it is necessary to set up a corresponding experimental system, such as figure 2 As shown, among them,

[0062] Precisely printed or drawn orthogonal scale markings with a certain interval along the circumferential and height directions on the side wall of the storage tank are used as position coordinate scales and height scales, and the storage tank contains translucent liquid to be measured. The orthogonal fringe pattern is printed or adhered (or placed) on the bottom of the tank, and the orthogonal fringe pattern can be set as a translucent fringe pattern with a specific frequency and size according to the needs of practical applications. A reflector group composed of four reflectors with the same specifications is arranged symmetrically around the storage tank, including: reflectors a, b, c, and d, wherein reflectors a and b are arranged ...

Embodiment 3

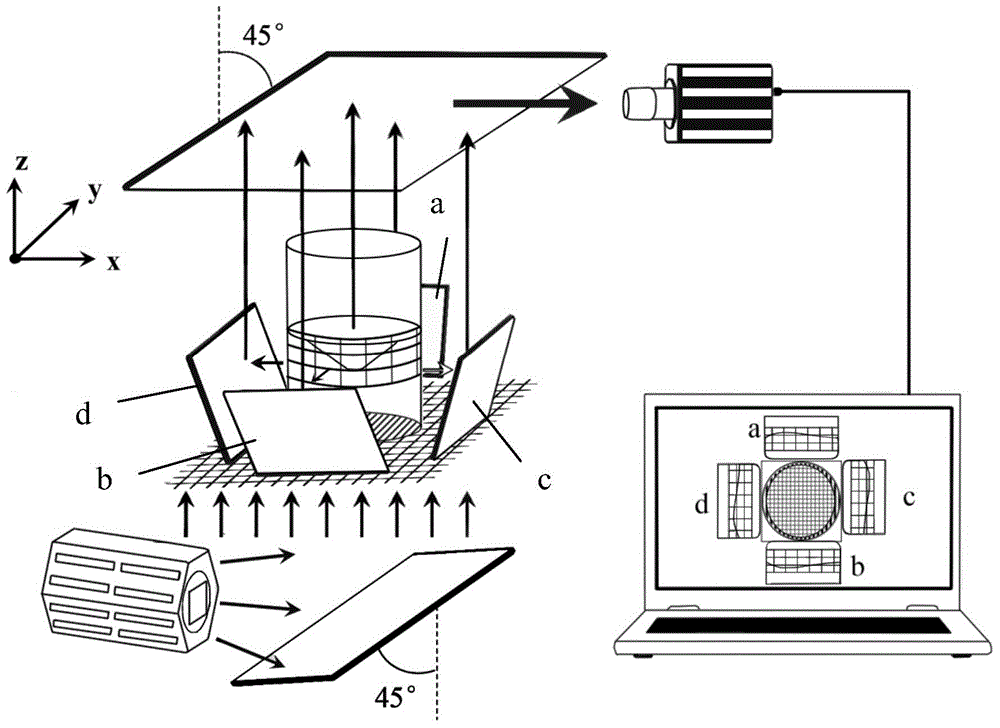

[0076] combine Figures 3 to 5 , the liquid propellant liquid surface morphology and dosage dynamic measurement method of the tank liquid propellant in this embodiment are specifically described:

[0077] The storage tank is an example of a cylindrical transparent flat-bottomed storage tank, and a storage tank with a square shape or other shapes with a horizontal bottom is also applicable.

[0078] The test system built is as follows:

[0079] Such as image 3 As shown, the orthogonal scale markings with a certain interval are accurately printed or drawn on the side wall of the tank along the circumferential direction and the height direction as the position coordinate scale and height scale. In order to realize the subsequent iterative calculation, the circumferential scale mark The whiskers are normal to the main direction of the stripes. The storage tank contains the translucent liquid to be tested. Design a semi-transparent orthogonal fringe pattern with specific frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com