Lower-iron-yoke shielding structure of transformer and manufacturing technology of lower-iron-yoke shielding structure of transformer

A technology of shielding structure and manufacturing process, applied in the direction of inductor/transformer/magnet manufacturing, magnetic field/electric field shielding, preventing/reducing unwanted electric/magnetic influences, etc. Partial discharge temperature, inability to play a shielding role, etc., to avoid damage or unreliable connection, excellent shielding performance, and stable shielding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

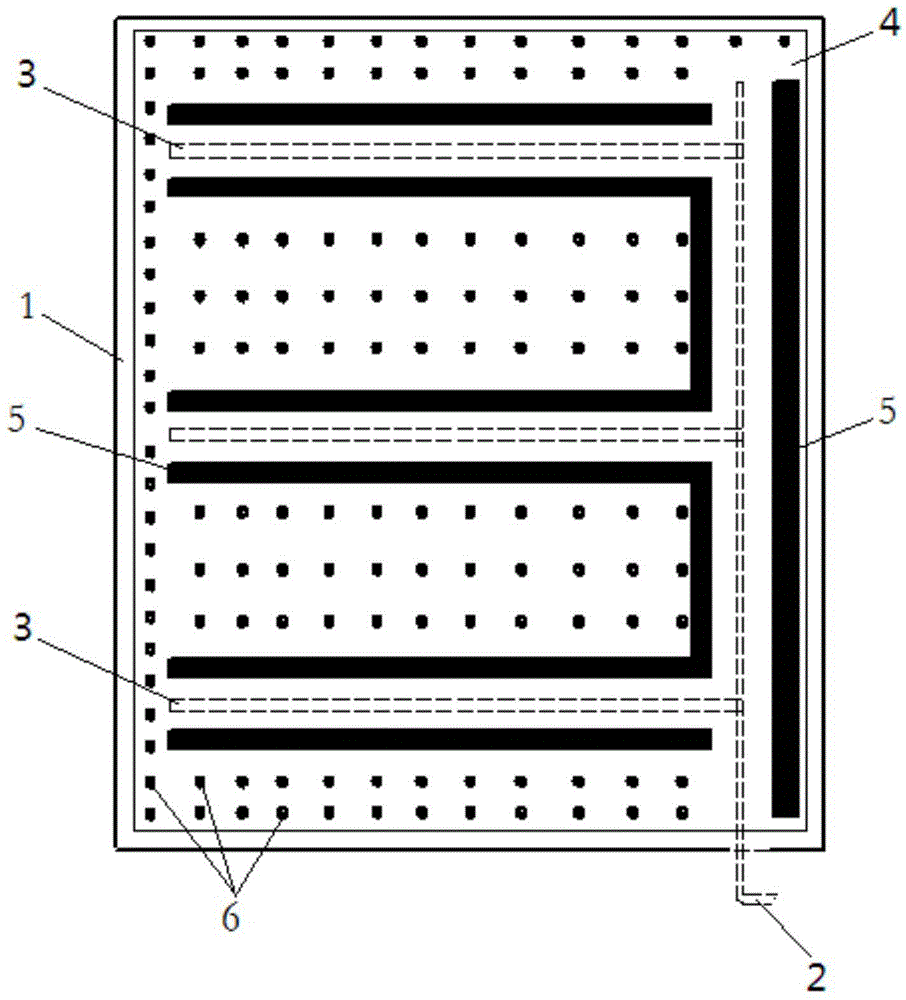

[0028] A lower iron yoke shielding structure of a transformer in the present invention, such as figure 1 As shown, it includes insulating paperboard 1, laying lead-out wire 2 and shielding wire 3 bonded on insulating paperboard 1, and wrinkled carbon black conductive paper 4; lead-out wire 2 and shielding wire 3 are connected, and wrinkle carbon black conductive paper 4 passes through The bonding structure arranged on the outside of the lead wire 2 and the shielding wire 3 is bonded and fixed to the insulating cardboard.

[0029] Among them, the lead-out wires 2 are vertically connected with several mutually parallel shielded wires 3 respectively; the lead-out wires 2 are made of copper braid, and the ends of the copper braid are provided with soldering heads; the shielded wires 3 are made of copper tape, and the lead-out wires 2 and the shielded wire 3 are fixed by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com