MCOB LED package structure

A packaging structure, LED chip technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of failure, heat can not be quickly transferred to the heat sink of lamps, heat cannot be quickly separated and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

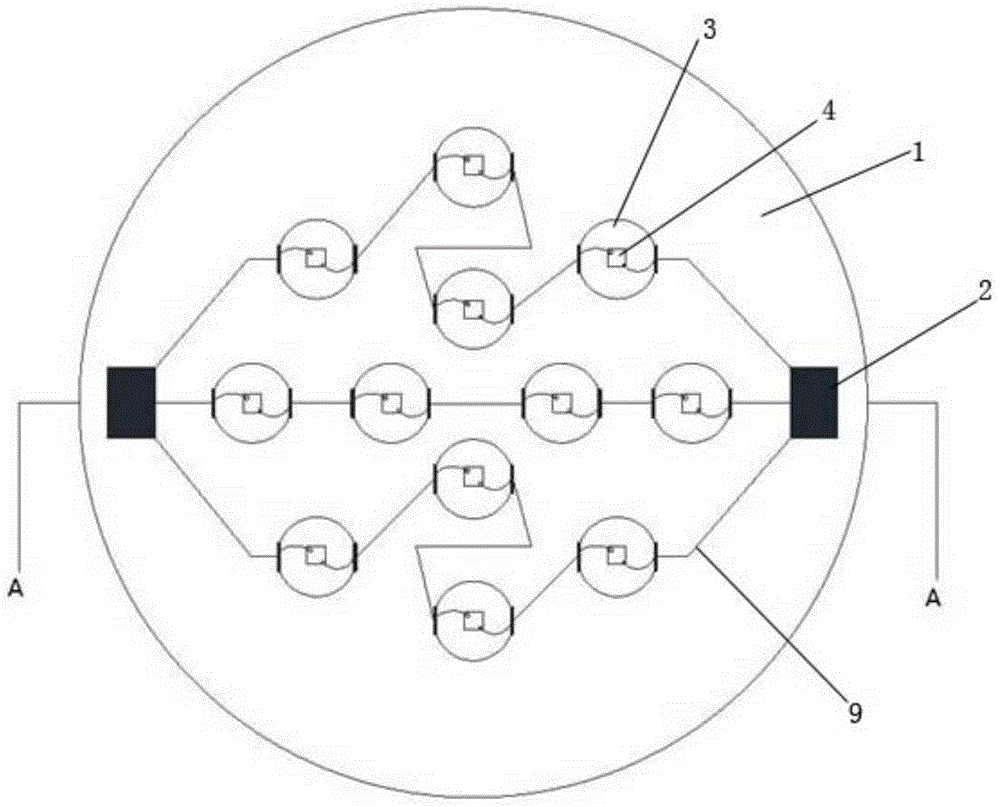

[0021] See attached figure 1 , which are schematic structural diagrams of an MCOB LED packaging structure according to an embodiment of the present invention.

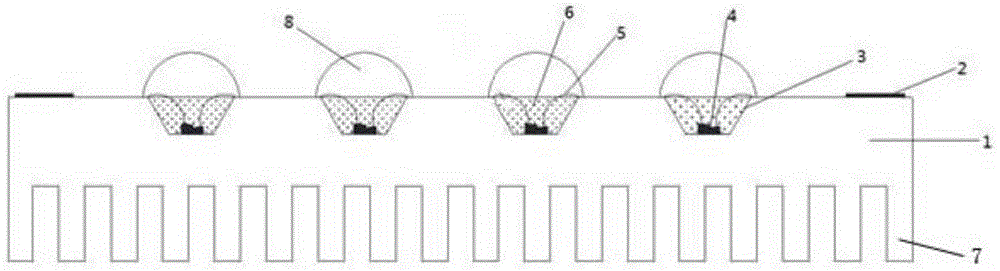

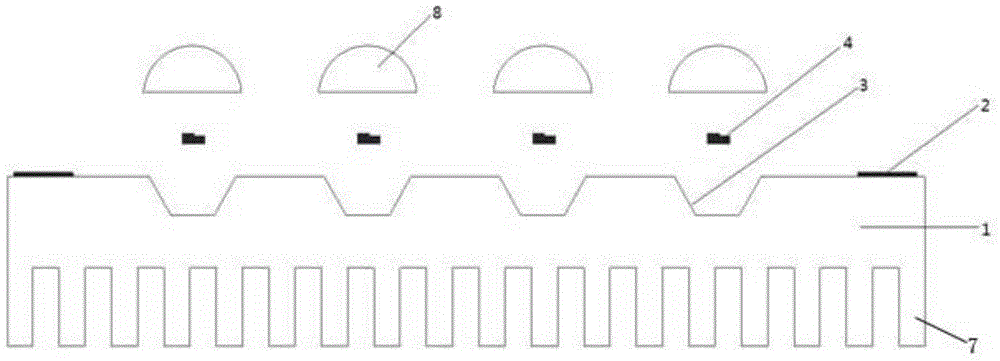

[0022] The MCOB LED packaging structure includes a substrate 1 and twelve LED chips 4 . The base plate 1 adopts a metal material with high thermal conductivity and is integrally formed. In other embodiments, the base plate 1 can also be made of ceramic material or polymer composite material with high thermal conductivity.

[0023] The substrate 1 includes a first surface and a second surface opposite to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com