Minimally invasive bone fetcher

A bone chip and collection container technology, applied in the field of minimally invasive bone harvester, can solve problems such as easy sequelae, patient injury, and inconvenience of bone harvesting, and reduce the risk of injury to the lateral femoral cutaneous nerve. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

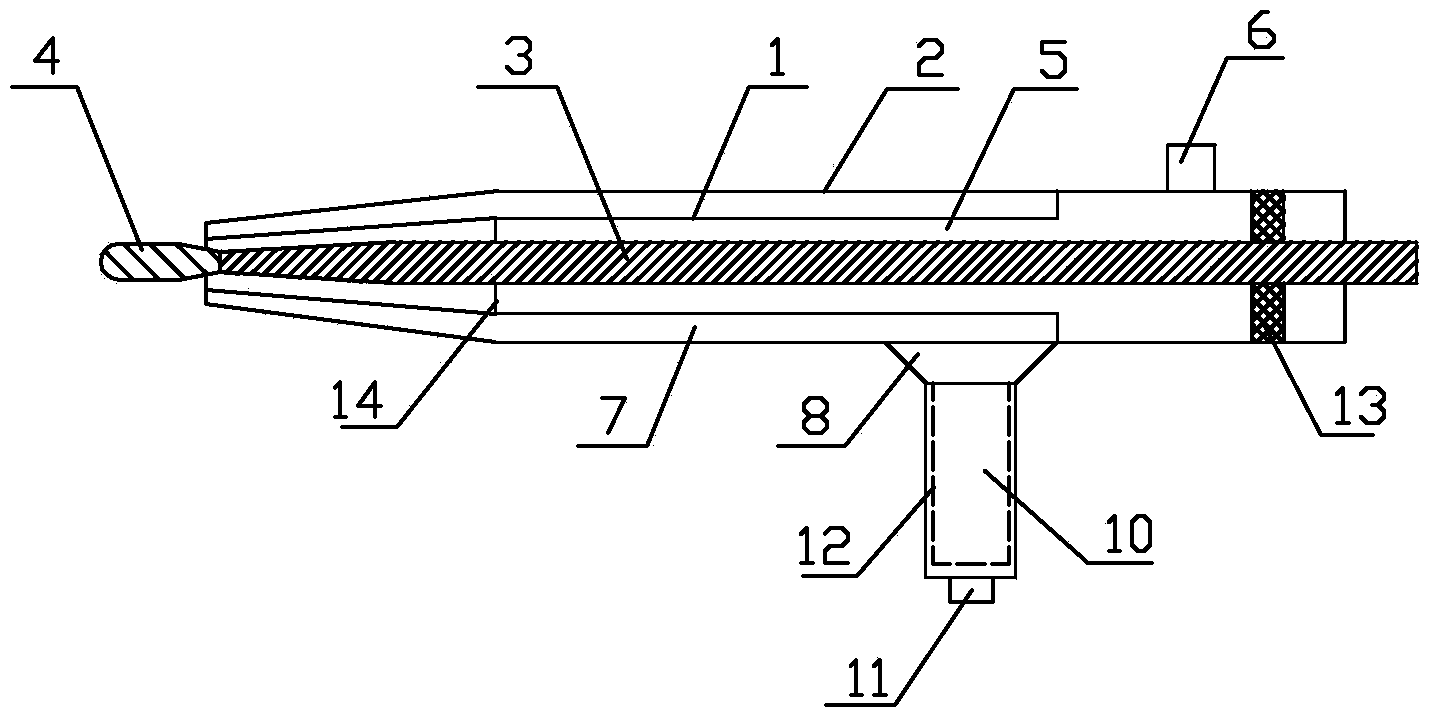

[0027] Embodiment 1: the minimally invasive bone extractor of the present embodiment, such as figure 1As shown, it includes a sleeve 20, a connecting rod 3 located on the axis of the sleeve and a drill bit 4 connected to the front end of the connecting rod 3. The sleeve 20 adopts a double-layer sleeve, and the double-layer sleeve includes a connected inner layer sleeve Cylinder 1 and outer sleeve 2, inner sleeve 1 and outer sleeve 2 are arranged coaxially, inner sleeve 1 has a shoulder, the inner sleeve in front of the shoulder is thinner, and the thinner inner sleeve There is an outer sleeve 2 connected to the outer sleeve of the sleeve, and the inner sleeve behind the shoulder is thicker. There is a water inlet 6 on the thicker inner sleeve, and the water inlet is set vertically upward. The inner sleeve 1 and the connecting rod 3 A water inlet channel 5 is formed between them, and the water inlet channel 5 communicates with the water inlet 6. A discharge channel 7 is formed ...

Embodiment 2

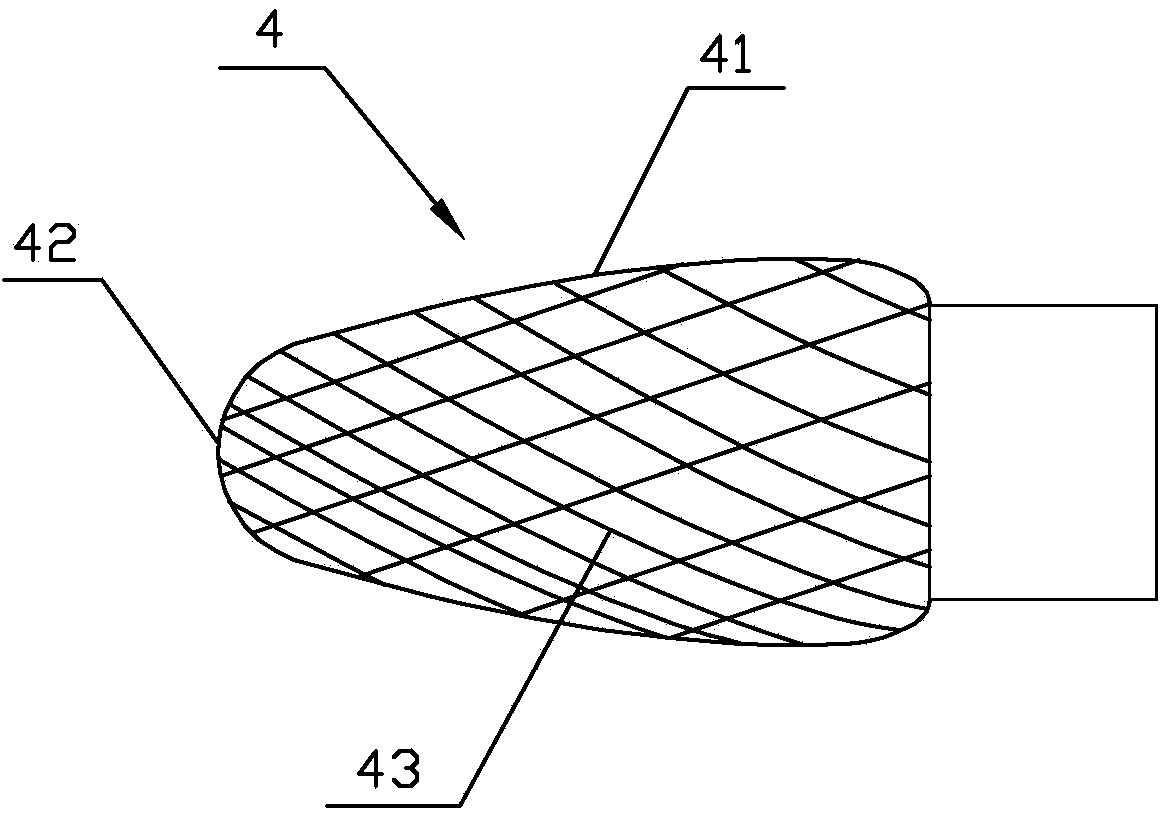

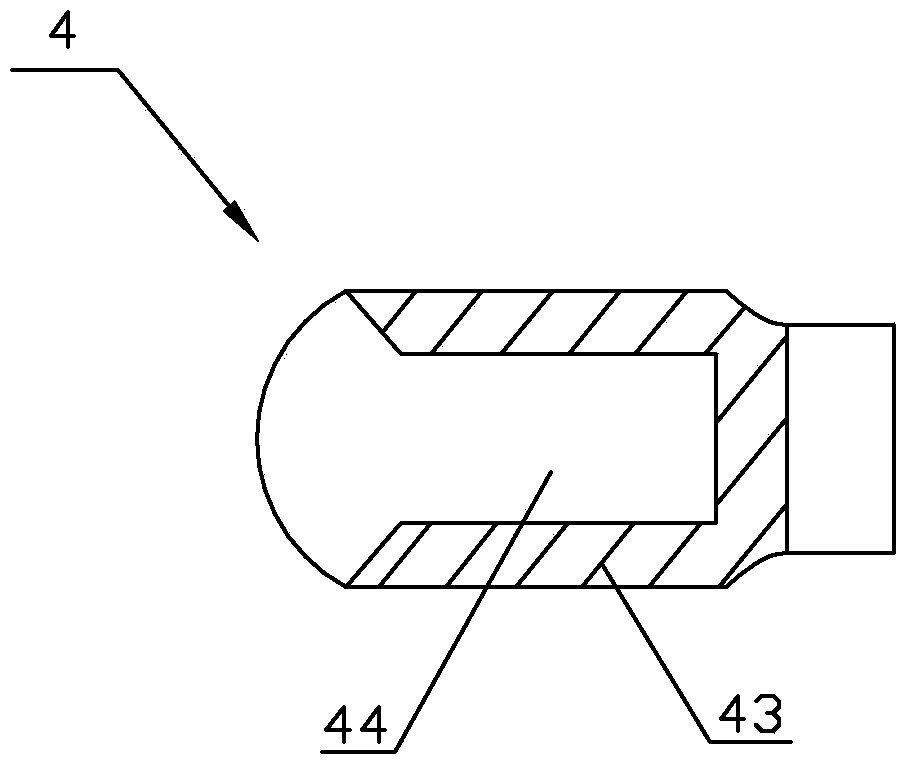

[0029] Embodiment 2: the minimally invasive bone extractor of the present embodiment, such as image 3 As shown, the front end of the drill bit 4 is a spherical surface 42, and the side of the drill bit 4 has three strip-shaped grooves 44 axially arranged, and the three grooves are evenly distributed along the circumferential surface of the drill bit, and the rear end of the groove 44 Near the rear end of the drill bit 4 , the front end of the groove 44 is open at the front end of the drill bit 4 , and the side of the drill bit 4 except the groove 44 has a blade 43 which is arranged obliquely. All the other structures are with embodiment 1.

[0030] The groove mouth is equivalent to the blade set in the axial direction, which is powerful and convenient for grinding drills. Combined with the blade set at an angle, it can quickly grind down the bone debris. Important tissue structure of the patient.

Embodiment 3

[0031] Embodiment 3: the minimally invasive bone extractor of the present embodiment, such as Figure 4 As shown, the rear end of the connecting rod 3 is connected to the rotary drive device. In the present embodiment, the rotary drive device is a small hand-held electric drill 15, and the rear end of the connecting rod 3 is connected to the motor 151 in the hand-held electric drill 15. The rear end of the layer sleeve (that is, the rear end of the thicker inner layer sleeve) is clamped with the shell of the hand-held electric drill 15. A battery for powering the motor is installed in the handle 152 of the hand-held electric drill 15, and a switch 153 for controlling the power on and off of the motor is installed on the handle 152 of the hand-held electric drill 15. All the other structures are with embodiment 1.

[0032] The doctor can operate it by holding the handle of the hand-held electric drill, and can control the switch at the same time when holding it. It is labor-sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com