Single-box vacuum oil immersion device and oil immersion method thereof

A technology of vacuum immersion and tank, which is applied in the field of vacuum oil immersion device and its oil immersion, which can solve the problems of large labor load of lubricating oil, numerous connecting pipes, waste of lubricating oil, etc., and achieves simple structure, low test cost, and oil immersion easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

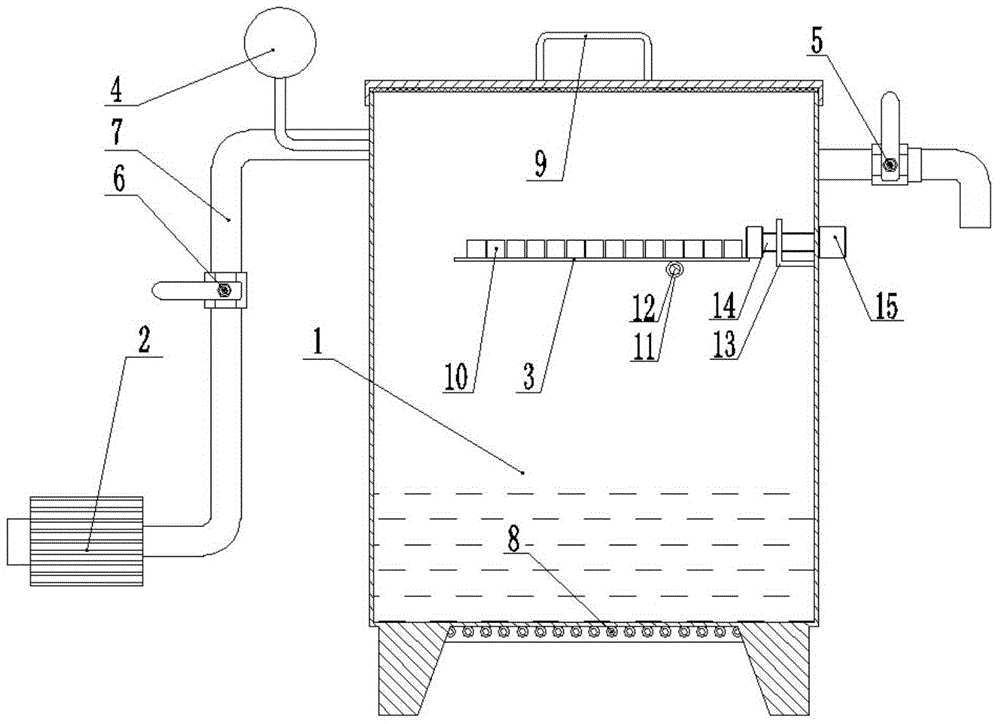

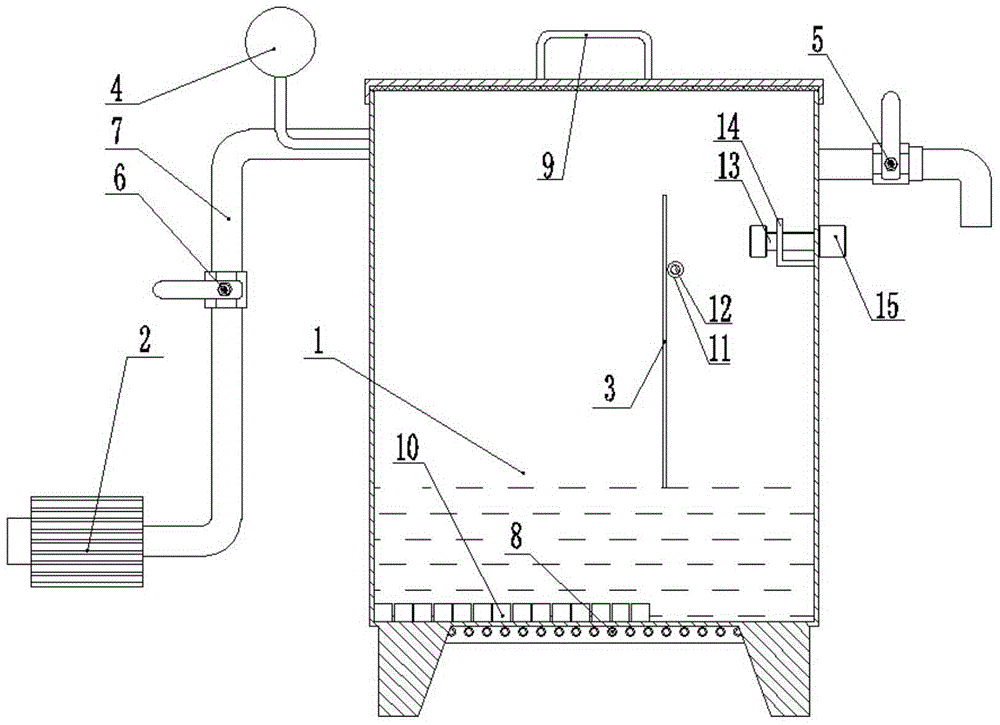

[0028] figure 1 It is a schematic diagram before oil immersion when the single box vacuum oil immersion device of the present invention uses the L bracket tilting mechanism; figure 2 It is a schematic diagram of oil immersion when the single box vacuum oil immersion device of the present invention uses the L bracket tilting mechanism; figure 1 , figure 2 The present invention is further described.

[0029] A single-box vacuum oil immersion device of the present invention includes a closed oil immersion tank 1 composed of a tank cover and a box body, a vacuum pump 2 connected to the oil immersion tank 1 with a vent pipe 7, and a storage board located in the oil immersion tank 3, and a tilting mechanism for tilting the shelf 3 or a lifting mechanism for lifting the shelf 3; a vacuum gauge 4 and an air release valve 5 are arranged on the box cover or on the upper side wall of the box; A pressure maintaining valve 6 is arranged on the ventilation pipe 7; the tilting mechanism...

Embodiment 2

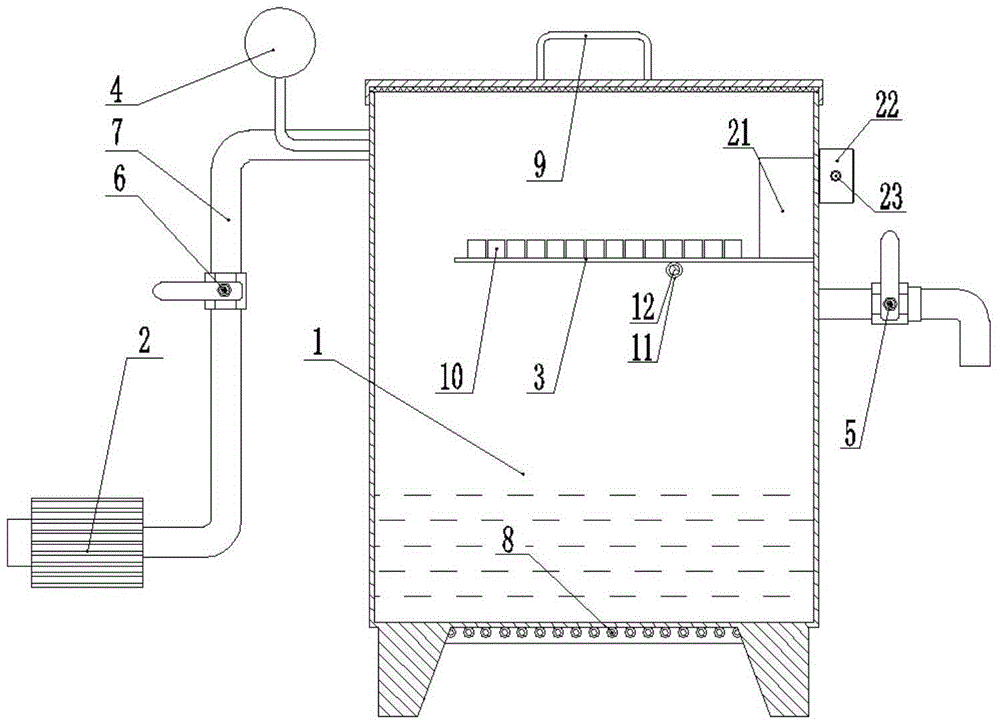

[0039] see image 3 with Figure 4 , the structural form of the single-box vacuum oil immersion device in this embodiment is: a cam tilting mechanism is used to replace the L bracket tilting mechanism in Embodiment 1, and the tilting mechanism is located at the top of the box, including the end face welded on the box. Rotating ring 11, rotating shaft 12, cam 21, runner 22 fixedly arranged on the storage board 3, and handle 23 welded or threaded with the rotating wheel 22; the inner hole gap between the rotating shaft 12 and the rotating ring 11 Cooperate; the runner 22 and the handle 23 are located outside the box body, the runner 22 is connected with the cam 21 through the connecting shaft passing through the side wall of the box body, and a Sealing ring; when the boundary point of the cam 21 farthest from the base circle is in contact with the storage board 3, the storage board 3 is horizontal.

[0040] The steps of the oil immersion process using the device described in t...

Embodiment 3

[0044] see Figure 5 , the structural form of the single box vacuum oil immersion device in the present embodiment is: use the runner lifting mechanism to replace the L bracket tilting mechanism in embodiment 1, the lifting mechanism is located at the top of the casing, including lifting rope 31, lifting shaft 32, Runner 22, and the handle 23 that is welded or threaded with runner 22, one end of lifting rope 31 is tied on the storage board 3, and the other end is wound on the lifting shaft 32, and the two ends of lifting shaft 32 are fixed on the case by rotating connection. On the body, the runner 22 and the handle 23 are located outside the box body, the runner 22 is connected with the lifting shaft 32 through the connecting shaft passing through the side wall of the box body, and a sealing ring is arranged between the connecting shaft and the side wall of the box body , an oil hole is provided on the storage board 3 .

[0045] Use the oil immersion process step of this dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com