Energy feedback type damper combining piezoelectric ceramic and magnetorheological fluid

A technology of magnetorheological fluid and piezoelectric ceramics, applied in liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of limited use area, ineffective use of electric energy, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

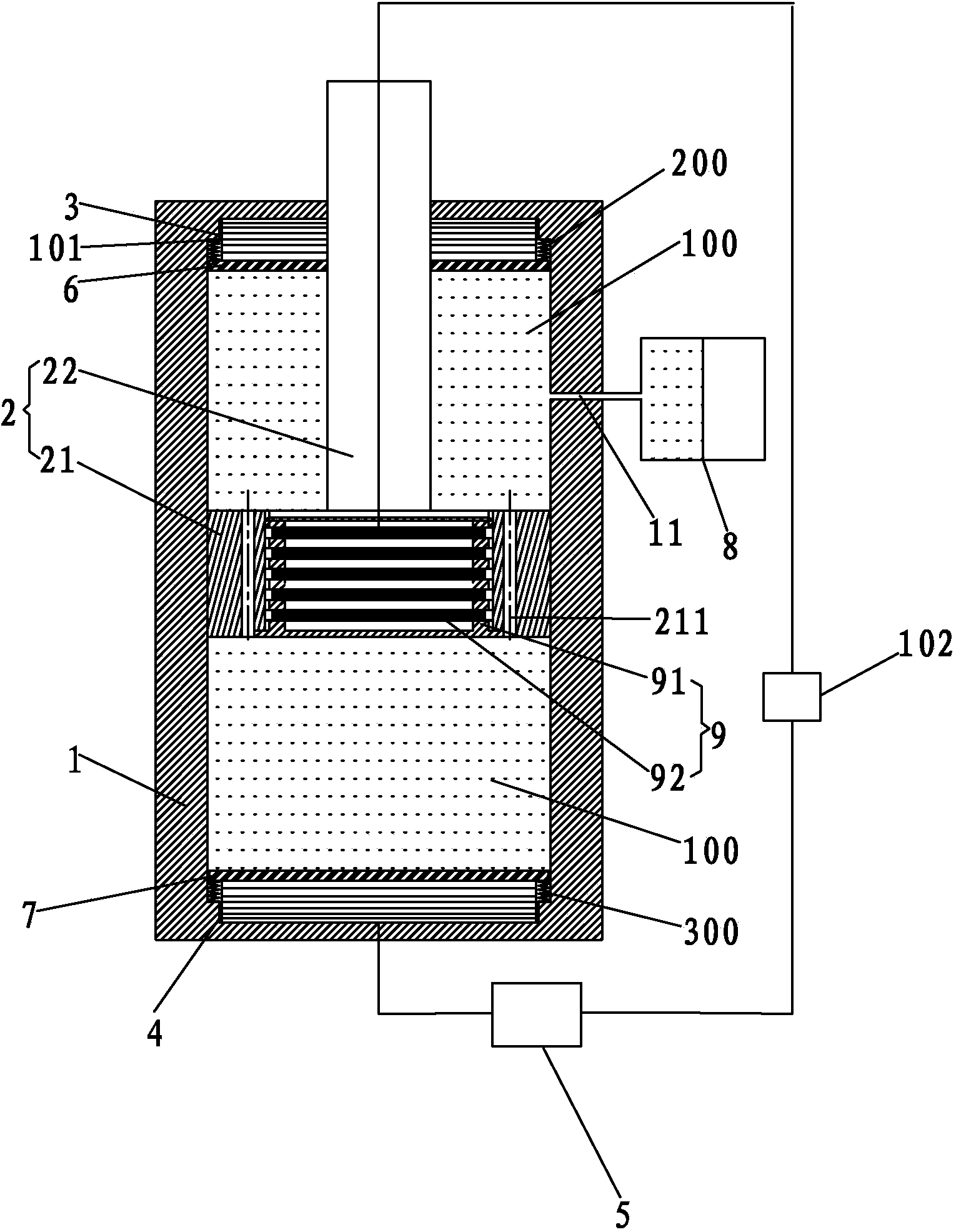

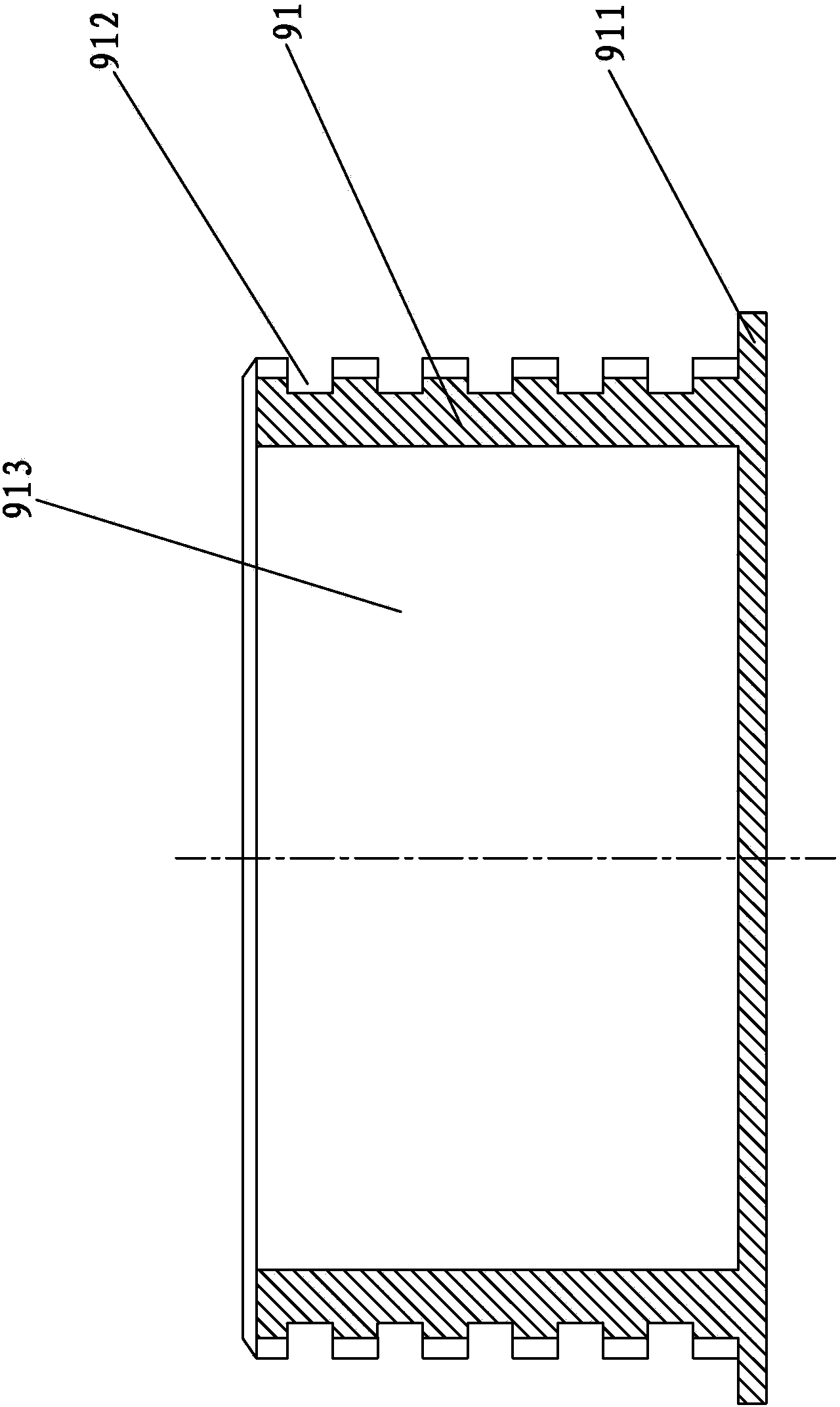

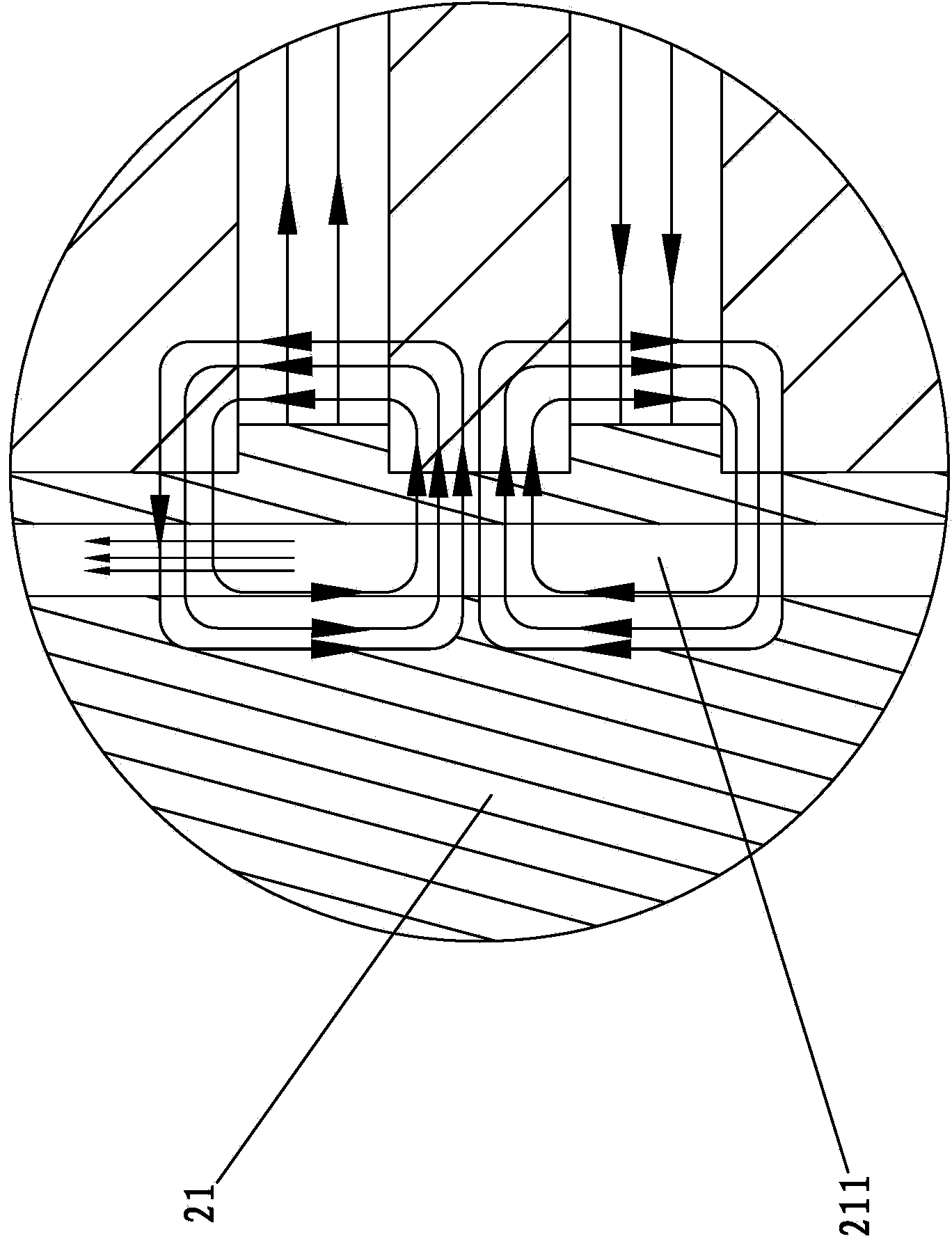

[0029] The energy-feeding damper combined piezoelectric ceramics and magnetorheological fluid of the present invention, such as Figure 1-3 As shown, it includes a cylinder 1, a piston rod 2, an upper piezoelectric generating unit 3 and a lower piezoelectric generating unit 4 inside the cylinder 1, and an electric energy extraction and storage unit 5 and a control unit outside the cylinder 1; :

[0030] The cylinder body 1 is a hollow cylindrical structure with closed upper and lower ends. The piston rod 2 has a plug body 21 and a rod body 22 vertically connected to the upper surface of the plug body 21. The plug body 21 is located in the cylinder body 1, and Sealed with the inner side wall of the cylinder body 1 , the rod body 22 is erected in the cylinder body 1 , and the upper end of the rod body 22 protrudes tightly out of the upper surface of the cylinder body 1 .

[0031] The upper piezoelectric power generation unit 3 is set outside the upper end of the rod body 22. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com