Anti-corona special enameled wire for wind power generation and production method

A production method and enameled wire technology, applied in power cables, circuits, insulated cables, etc., can solve problems such as poor anti-corona performance, low breakdown voltage, poor adhesion, and poor flexibility, and achieve excellent anti-corona performance, Good chemical properties, high breakdown voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

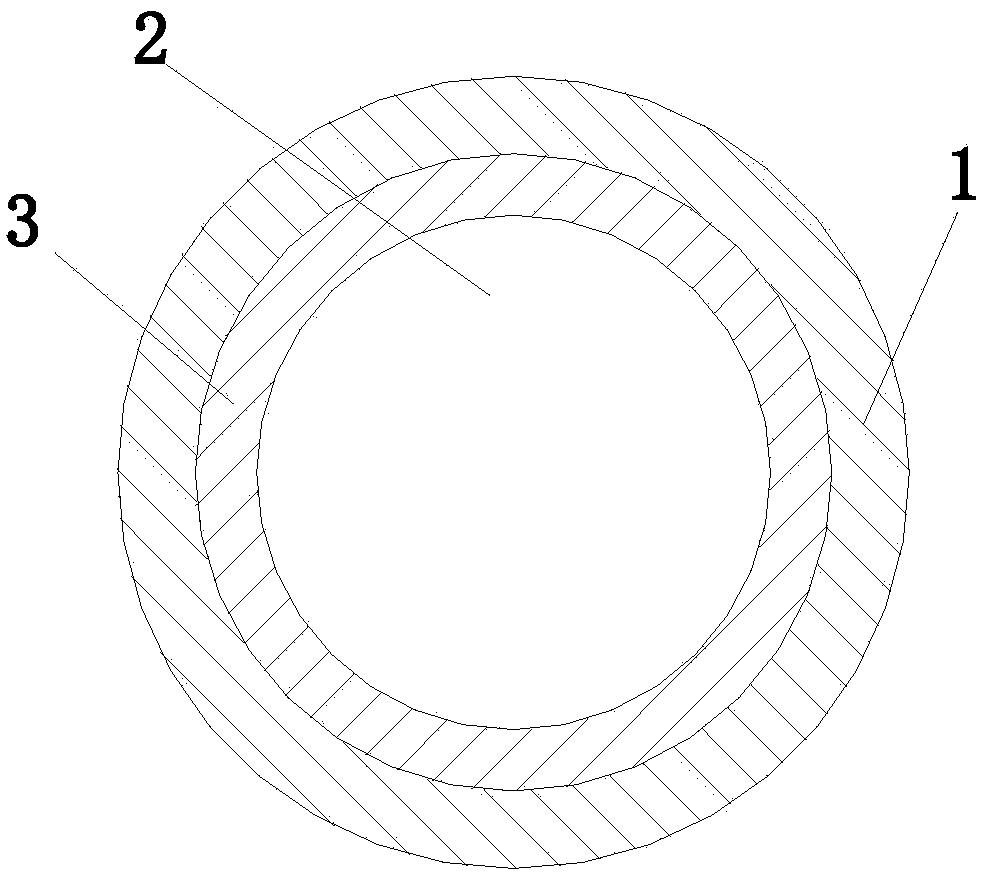

[0014] Example. Anti-corona special enameled wire for wind power generation, composed of figure 1 As shown, it includes a copper round wire 1, and the surface of the copper round wire 1 is sequentially provided with a polyesterimide paint layer 2, a corona-resistant paint layer 3 and a polyamideimide paint layer from the inside to the outside. Paint layer 2 thickness: corona resistant paint layer 3 thickness: polyamideimide paint layer thickness = 4:4:2.

[0015] The total thickness of the polyesterimide paint layer 2, the corona-resistant paint layer 3 and the polyamideimide paint layer is 0.067mm-0.072mm.

[0016] According to the production method of the aforementioned anti-corona special enameled wire for wind power generation, it is characterized in that: the copper round wire is annealed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com