Multi-needle vertical grounding body

A vertical grounding and pin-type technology, which is applied in the direction of connecting contact materials, can solve the problems that the grounding resistance value is difficult to meet the requirements, and the metal components are easy to corrode and fail, so as to achieve enhanced spark discharge function, long service life, and improved discharge speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

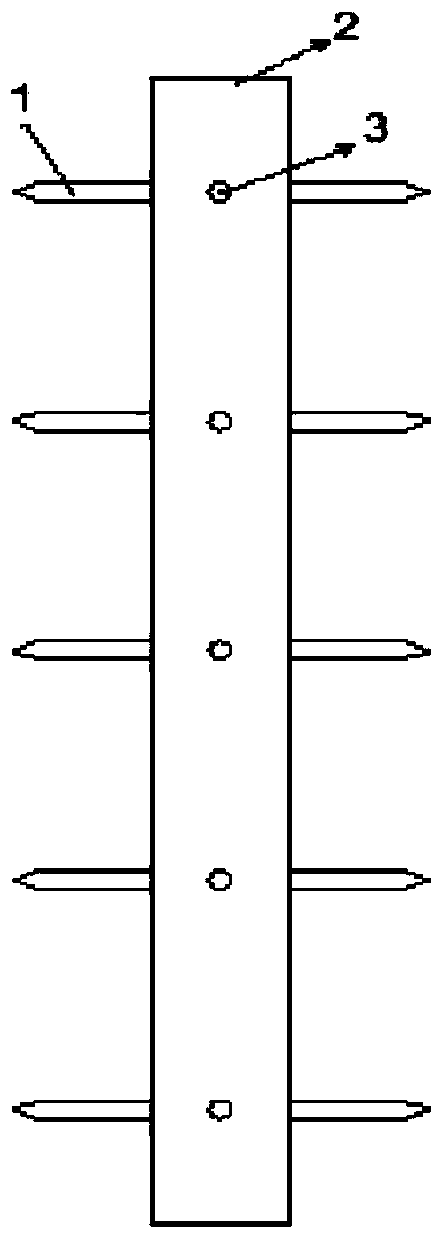

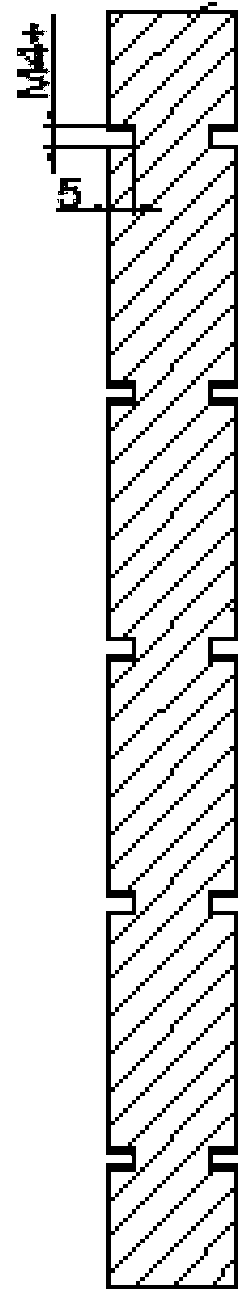

[0017] Such as figure 1 For the multi-pin vertical grounding body shown, connect the needle discharge electrode 1 at the connection point 3 (see figure 2 ) and vertical ground rod 2 (see image 3 ) for connection, the vertical ground rod is made of copper composite material.

[0018] More specifically:

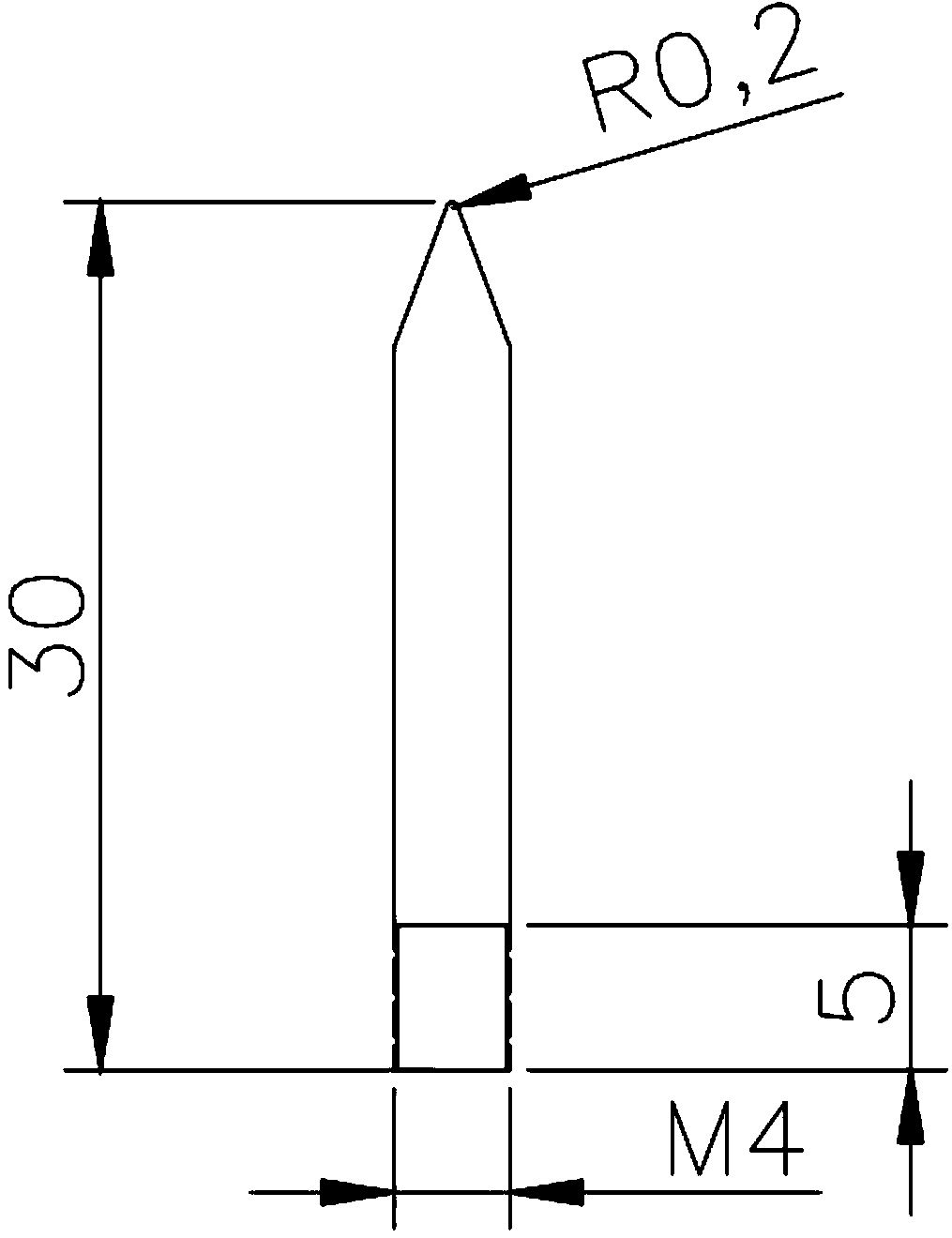

[0019] Needle discharge electrode 1 (see figure 2 ) is made of copper; its length is 30 mm, its radius is 2 mm, its tip is curved at 0.2 mm, and its tail is attached with a 5 mm long external thread;

[0020] Connection point 3 (see image 3 ) perpendicular to the rod-shaped vertical grounding body, with a depth of 5mm, and an internal thread that matches the needle-shaped discharge electrode 1, and its respective rules on the grounding rod body are: distributed on the rod body in layers, and the lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com