Graphite composite grounding body capable of reducing impact grounding resistance and preparation method for the same

A technology of impact grounding resistance and composite grounding, which is applied in the direction of connections, circuits, electrical components, etc., can solve the problem that the current is difficult to be effectively dissipated, and achieve the effects of improving conductor utilization, significant application effect, and enhanced group reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

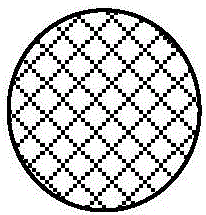

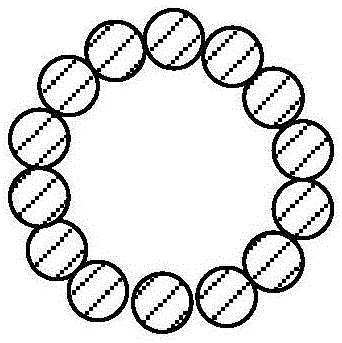

[0058] A single mullite fiber with a diameter of 10mm is used to form the inner core of the skeleton, and 12 graphite wires are arranged vertically and closely outside the inner core of the skeleton to form a graphite wire layer, and 24 composite graphite wires and 12 graphite wires are used to vertically and closely arrange the graphite wires. The composite graphite wire layer is formed outside the graphite wire layer, and the metal fiber used in the composite graphite wire is copper fiber with a diameter of 0.8mm. 24 graphite wires are used to cross weave outside the composite graphite wire layer to obtain a graphite wire braided layer. In this embodiment, the graphite wire used has a diameter of 2.2mm. The resistance per meter of the grounding body obtained in this embodiment was measured by the four-pole resistance measurement method, and it was 1 mΩ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com