Nontoxic non-residual soil processing and biological organic fertilizer combination method for preventing and controlling cucumber fusarium wilt

A technology of cucumber fusarium wilt and bio-organic fertilizer, which is applied in the fields of land preparation methods, applications, agricultural machinery and implements, etc., can solve problems such as considering cucumber fusarium wilt, and achieve the effects of saving expenses, increasing income, and using moderate costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

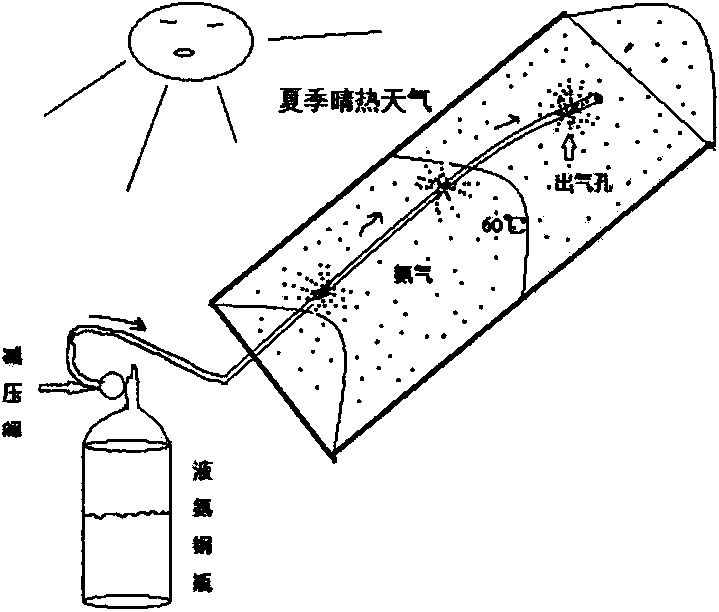

[0023] (1) Liquid ammonia fumigation

[0024] Plow the soil with frequent or severe occurrence of cucumber wilt to a depth of 25 cm. When the soil moisture content is below 30%, cover the plastic film and tighten the surrounding area. Pass one end of a pressure-resistant plastic tube equal to the length of the ridge into the plastic film ( figure 1 ), leave a small hole in the plastic pipe every 1.5-2.5 meters to let the liquid ammonia gasify and release it at multiple points in the shed to ensure its uniform concentration distribution. The other end of the pressure-resistant plastic pipe is connected to the pressure reducing valve of the special tank for the liquid ammonia cylinder ( figure 1 ), generally choose to open the hydraulic valve around noon and release liquid ammonia once a day for 2 minutes each time or when the ammonia concentration in the shed reaches 3500ml / m 3 Stop the air supply at the time, and put it 3-6 times in 300 square meters (depending on the severity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com