Water-based ink with high drying speed and preparation method thereof

A technology of water-based ink and water-based polyurethane, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of easy dry plate, increased printing cost, and shortened printing plate life, achieving long-term continuous printing, moderate use cost, The effect of excellent drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

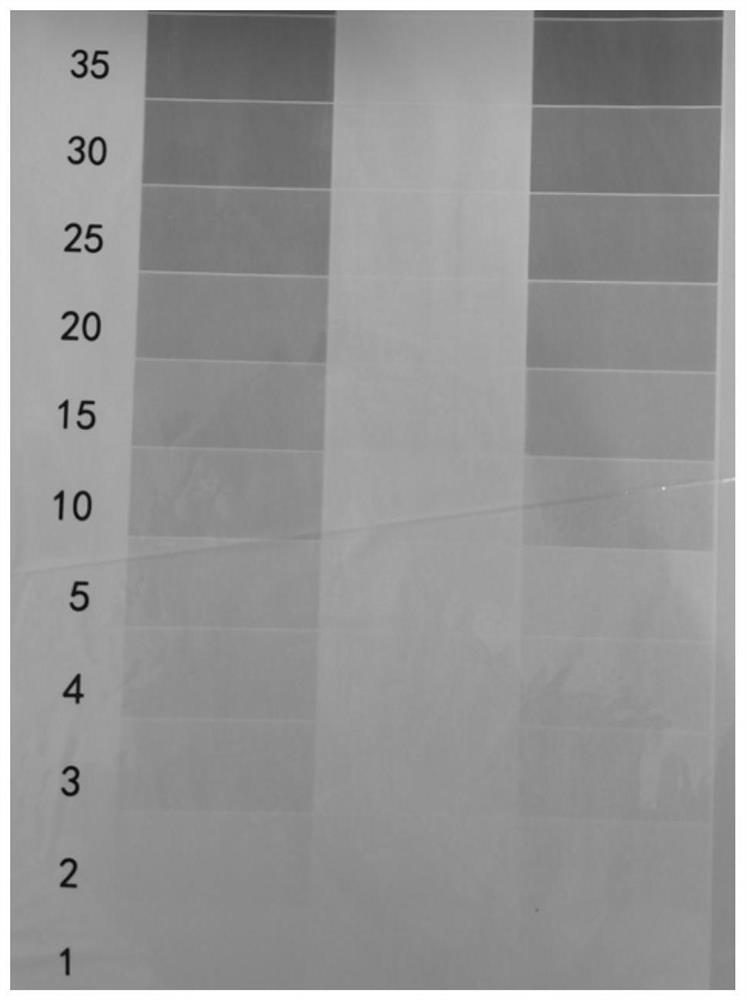

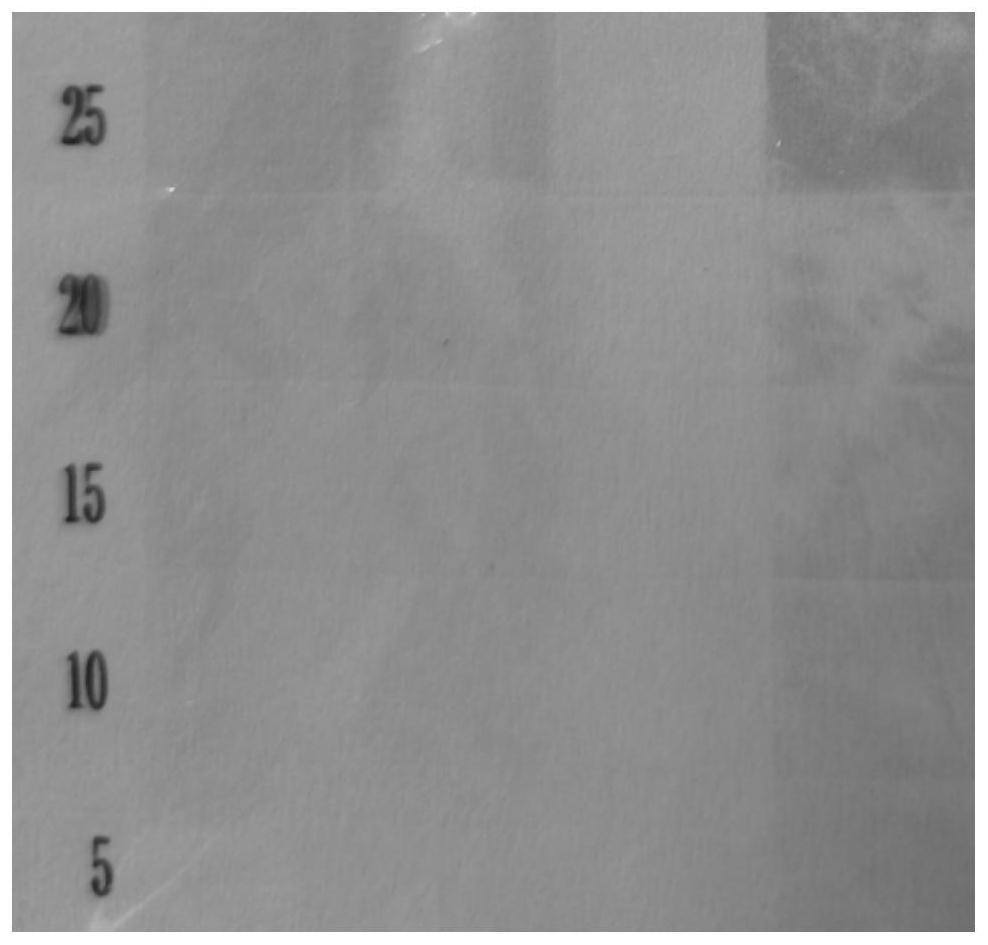

Image

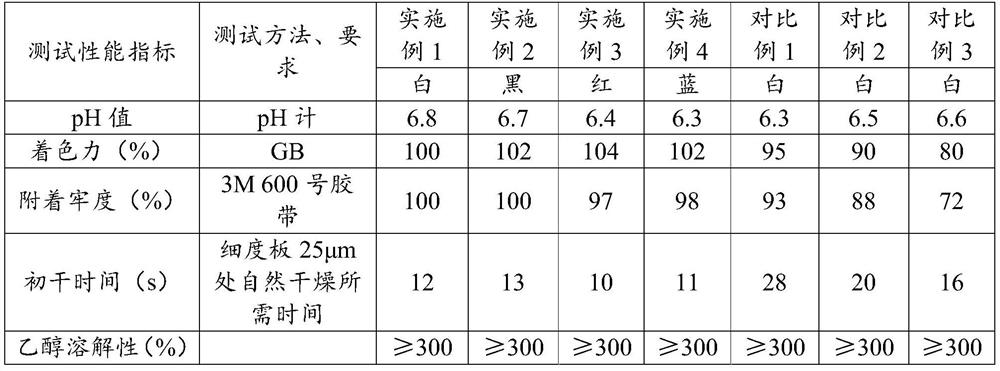

Examples

Embodiment 1

[0039] The present embodiment provides a kind of white water-based ink, comprises the component of following parts by weight:

[0040] 25 parts of epoxy-modified acrylic resin, 10 parts of camellia oil modified water-based polyurethane, 20 parts of butyl acrylate-dibutyl itaconate composite emulsion, 10 parts of white colorant, 0.5 parts of fumed silica, AMP-95 adjustment 0.6 parts of agent, 2 parts of dispersant, 1 part of slip agent, 1 part of hand feeling agent, 0.7 parts of leveling agent, 3 parts of water-based wax slurry, 5 parts of dipropylene glycol butyl ether, 6 parts of isopropanol, and 0.3 parts of defoamer , 13 parts of ethanol, 15 parts of deionized water.

[0041] Wherein, the preparation method of camellia oil modified water-based polyurethane comprises following components and steps in parts by weight:

[0042] Add 10 parts of camellia oil, 0.1 part of stannous octoate and 12 parts of isophorone diisocyanate into a container for reaction; then add 6 parts of ...

Embodiment 2

[0049] The present embodiment provides a kind of black water-based ink, comprises the component of following parts by weight:

[0050] 30 parts of epoxy-modified acrylic resin, 12 parts of camellia oil modified water-based polyurethane, 20 parts of butyl acrylate-dibutyl itaconate composite emulsion, 10 parts of black pigment, 0.5 parts of fumed silica, AMP-95 adjustment 0.8 parts of agent, 1 part of dispersant, 1 part of slip agent, 0.6 parts of hand feeling agent, 0.8 parts of leveling agent, 2 parts of water-based wax slurry, 5 parts of dipropylene glycol butyl ether, 7 parts of isopropanol, and 0.4 parts of defoamer , 10 parts of ethanol, 12 parts of deionized water.

[0051] Wherein, the preparation method of camellia oil modified water-based polyurethane comprises following components and steps in parts by weight:

[0052] Add 6 parts of camellia oil, 0.05 parts of stannous octoate and 8 parts of isophorone diisocyanate into the container for reaction; then add 5 parts ...

Embodiment 3

[0059] The present embodiment provides a kind of red water-based ink, comprises the component of following parts by weight:

[0060] 30 parts of epoxy-modified acrylic resin, 12 parts of camellia oil modified water-based polyurethane, 15 parts of butyl acrylate-dibutyl itaconate composite emulsion, 10 parts of red pigment, 1 part of fumed silica, AMP-95 adjustment 0.5 parts of agent, 2 parts of dispersant, 2 parts of slip agent, 0.8 parts of hand feeling agent, 0.6 parts of leveling agent, 3 parts of water-based wax slurry, 5 parts of dipropylene glycol butyl ether, 6 parts of isopropanol, and 0.3 parts of defoamer , 15 parts of ethanol, 15 parts of deionized water.

[0061] Wherein, the preparation method of camellia oil modified water-based polyurethane comprises following components and steps in parts by weight:

[0062] Add 9 parts of camellia oil, 0.1 part of stannous octoate and 10 parts of isophorone diisocyanate into a container for reaction; then add 6 parts of ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com