Bottom drive double parallelogram infinite rotary bevel cutting head

A groove cutting, double parallel technology, applied in the direction of welding/cutting auxiliary equipment, auxiliary equipment, gas flame welding equipment, etc., can solve the problems of energy consumption, cable and gas pipe entanglement, high cost, etc., to reduce the space occupied by the device , to avoid intertwining, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

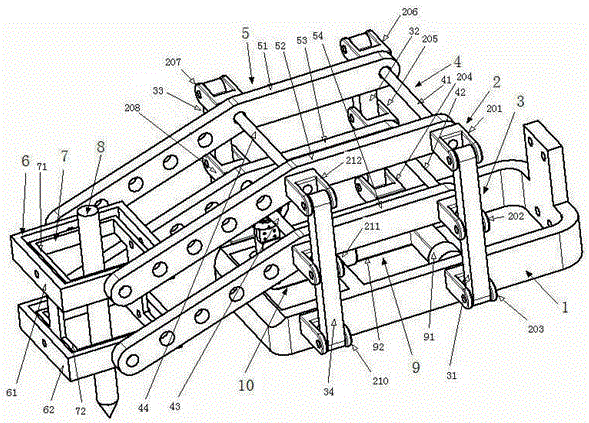

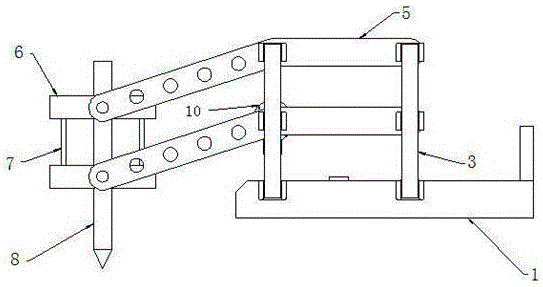

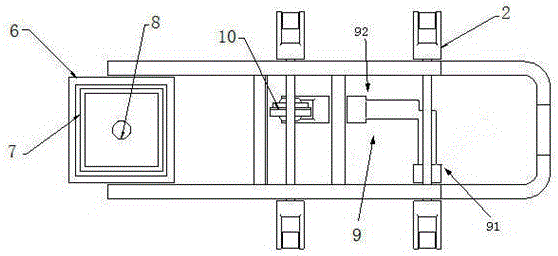

[0034] like Figure 1-4 As shown, a bottom drive type double parallelogram infinite rotary bevel cutting head includes a horizontal frame 1, a double parallelogram mechanism, a driving device 9, a cage connector 6, a cutter cage 7 and a cutter 8, The double parallelogram mechanism is set on the horizontal frame 1 and is movably connected with the horizontal frame 1; the driving device 9 is fixed on the horizontal frame 1 to drive the double parallelogram mechanism to swing and rotate; the cage The connector 6 is connected to one end of the double parallelogram mechanism ( figure 1 The left end side in the middle); the cutting tool cage 7 is arranged in the cage connecting piece 6, and is connected with the cage connecting piece 6 by a pin shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com