Processing method and roasting device of bamboo slices for mahjong mats

A processing method and technology for bamboo chips, which are applied in the directions of wood processing, wood processing details, wood processing appliances, etc., can solve the problems of uneven color throwing on the mat surface, residual harmful substances, high labor intensity, etc., and the method is feasible. , saving labor costs, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

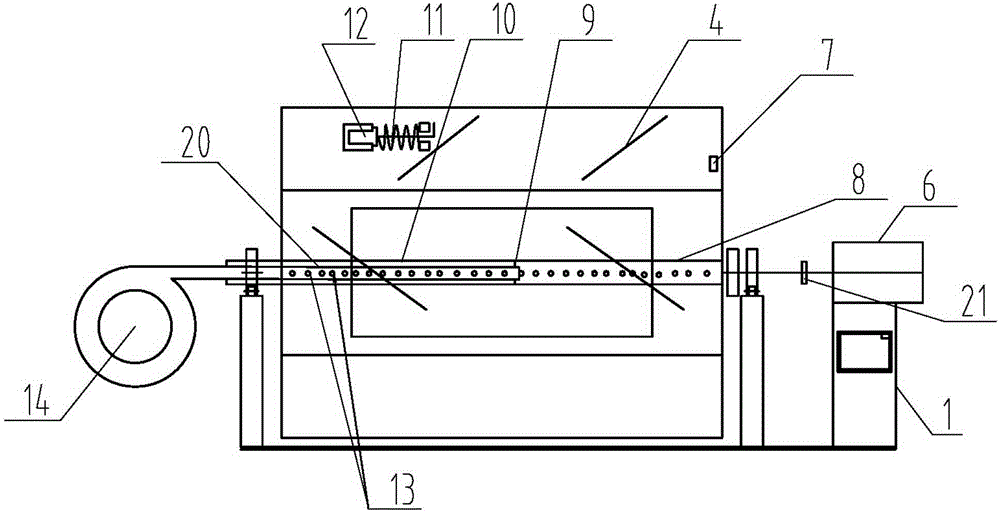

[0031] Depend on figure 1 , figure 2 As can be seen, a kind of processing method of mahjong mat bamboo chip, it comprises the following steps:

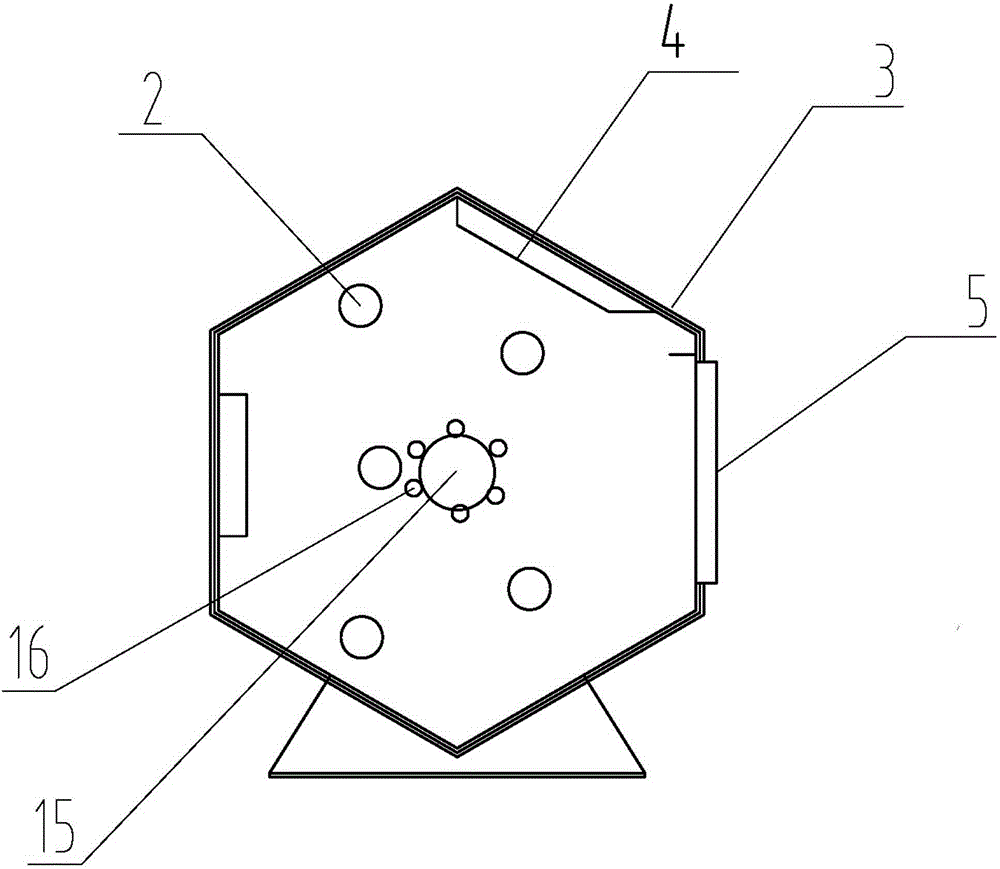

[0032] (1) Feeding: Pour the bamboo slices that have been drilled or drilled and flower-arranged into the frying device through the inlet and outlet 5; the humidity of the bamboo slices is about 20%, and the humidity of the bamboo slices in this embodiment is 10%. The frying device includes a cylinder 3 driven by power to rotate, a heating mechanism, an air exchange mechanism and a control mechanism for exchanging air inside and outside the cylinder 3, and the radial section of the cylinder 3 is a regular pentagon Or regular hexagonal or regular heptagonal or regular octagonal, (this embodiment is regular hexagonal) cylinder body 3 is provided with inlet and outlet 5 on the side wall;

[0033] Depend on image 3 It can be seen that the heating mechanism of the present invention includes at least two heaters 2 (five in this embodim...

Embodiment 2

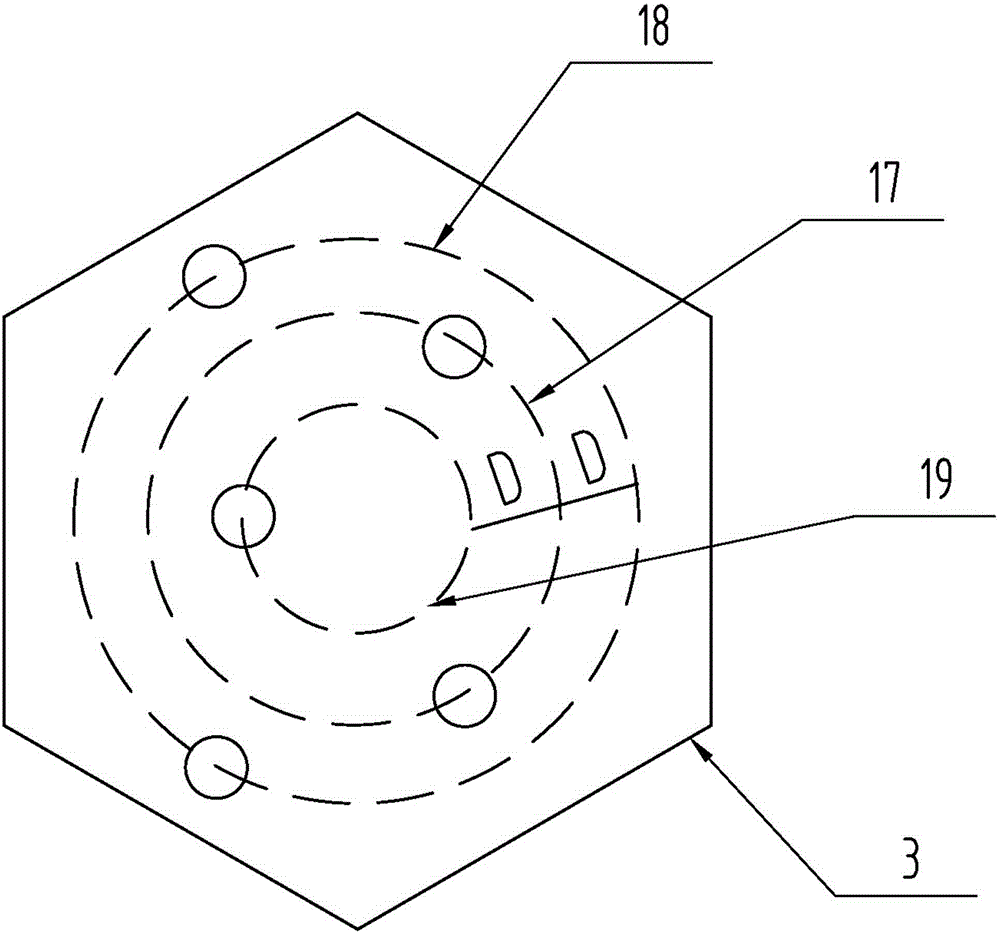

[0057] In this embodiment, there are three heaters 2, and the trajectory of the center of the heater 2 forms a circle on the end surface of the cylinder 3, and the circumference is evenly distributed on the end surface of the cylinder 3, so that the trajectory of the center of the heater 2 covers the entire cylinder 3. The circle described in this embodiment includes an inner circle 19, a middle circle 17 and an outer circle 18, wherein the inner circle 19, the middle circle 17 and the outer circle 18 are respectively provided with a heater 2, and three heaters 2 are installed in the cylinder body 3 It is substantially uniformly distributed, so that the heat generated by the three heaters 2 is substantially uniformly distributed in the cylinder body 3 . In this embodiment, the radius difference between the circumferences is D; in order to make the heat generation of the heater 2 be substantially evenly distributed in the cylinder 3, the power of the heater 2 on the inner circu...

Embodiment 3

[0062] The humidity of the bamboo chips in this embodiment is 30%, and the heat preservation time in step (3) of this embodiment is 120min; the heat preservation time in step (5) and step (7) is 60min; Example Raise the temperature inside cylinder 3 to 155°C.

[0063] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com