plastic cutting machine

A technology of plastic hot cutting machine and roller shaft, which is applied in metal processing and other directions, can solve the problems of plastic particles being susceptible to moisture, waste of energy, and increase of enterprise costs, so as to solve the problem of water pollution, avoid the waste of funds, and solve the problem of funds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

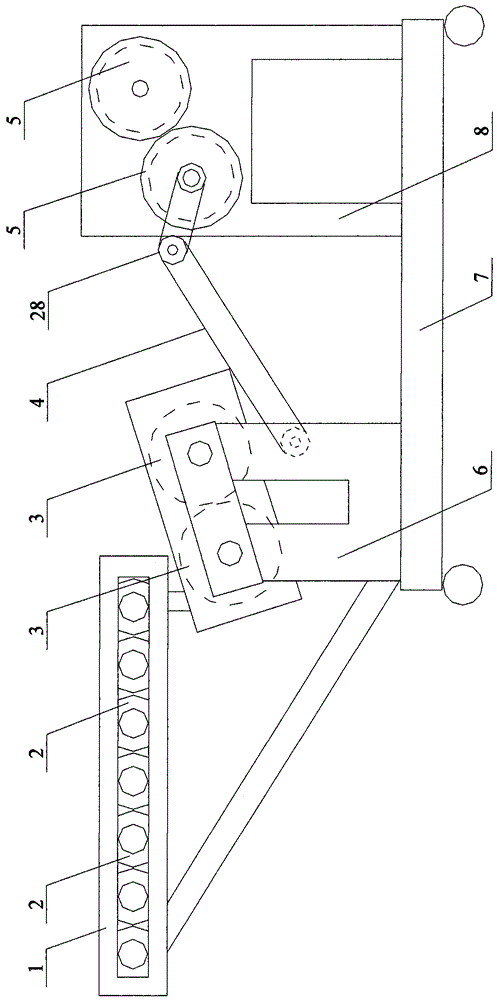

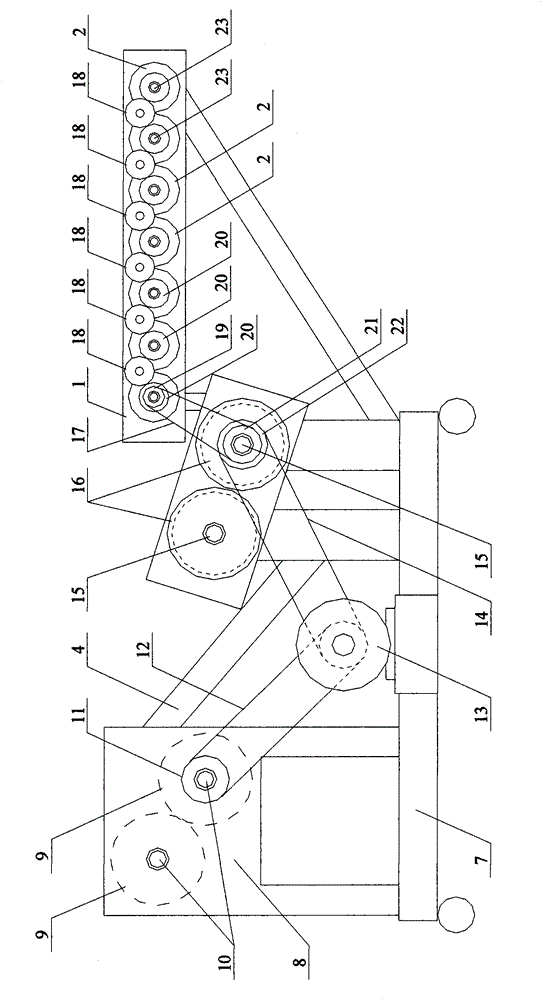

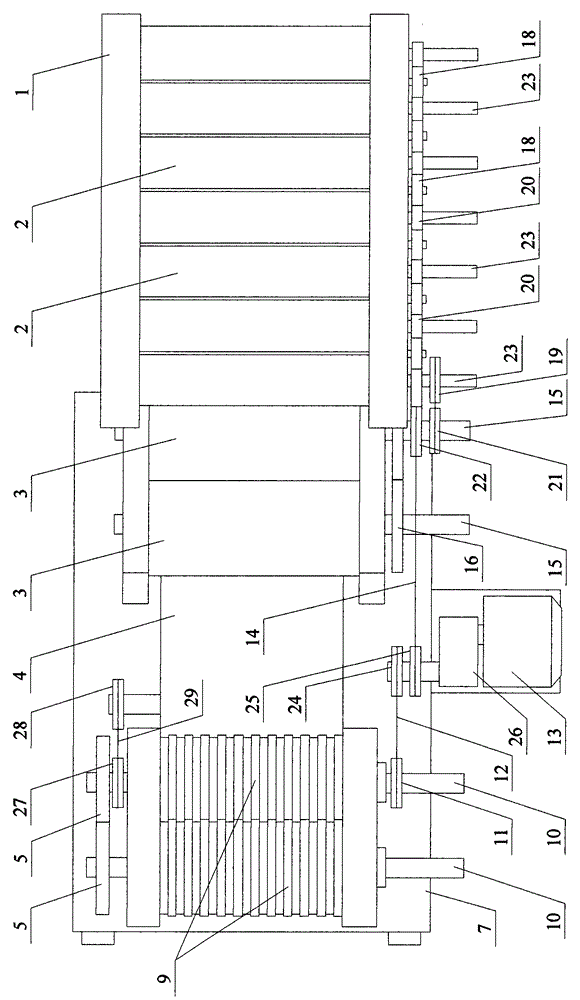

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0013] Such as Figure 1 ~ Figure 3 As shown, a plastic hot cutting machine involved in this embodiment includes: a roller frame 1, a hollow codirectional water-cooled chrome-plated shaft roller 2, two chrome-plated large pair of roller rollers 3, a rubber conveyor belt 4, two Roller cutter gear 5, first support 6, base 7, second support 8, cooling roller cutter 9, cooling inlet and outlet water pipe 10 of roller cutter, first sprocket wheel 11, first chain 12, motor 13, second Chain 14, roller inlet and outlet water pipe 15, two roller gears 16, transmission belt 17, transmission gear 18, first pulley 19, shaft roller gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com