Powder material fetching device

A material retrieving device and powder material technology, which is applied in the field of powder material reclaiming device, can solve the problems of large detection material analysis error, complex structure of the retrieving device, easy to be mixed with other substances, etc., to achieve convenient operation and no hygienic dead ends , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

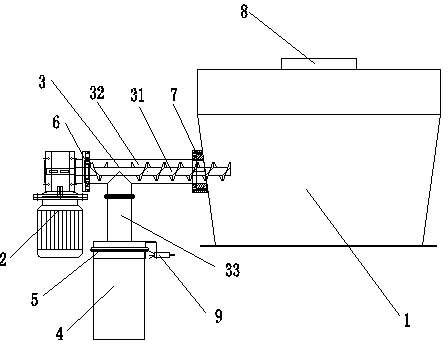

[0013] A reclaiming device for powder, such as figure 1 As shown, it includes a weighing machine bin 1, a geared motor 2 and a conveying mechanism 3 connected between the weighing machine bin 1 and the geared motor 2 for retrieving the material in the metering bin 1; the conveying mechanism 3 includes a screw 31 and the screw rod outer cylinder 32 that is used to install the screw rod 31, one end of the screw rod 31 links to each other with the reducer 2, and the other end stretches into the inside of the metering machine bin 1, and one end of the screw rod outer cylinder 32 is connected with the reducer 2, and the other end is connected with the reducer 2. The metering machine silo 1 is connected; the outer wall of the screw outer cylinder 32 is provided with a feeding pipe 33 connected with the screw outer cylinder 32 .

[0014] In order to better cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com