Water purification machine

A pure water machine and pure water technology, applied in the field of water treatment, can solve the problems of high production cost and after-sale maintenance cost, large internal space of the machine, large water leakage risk coefficient, etc., so as to reduce material cost and labor cost, and reduce the number of connection ports. , The effect of easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

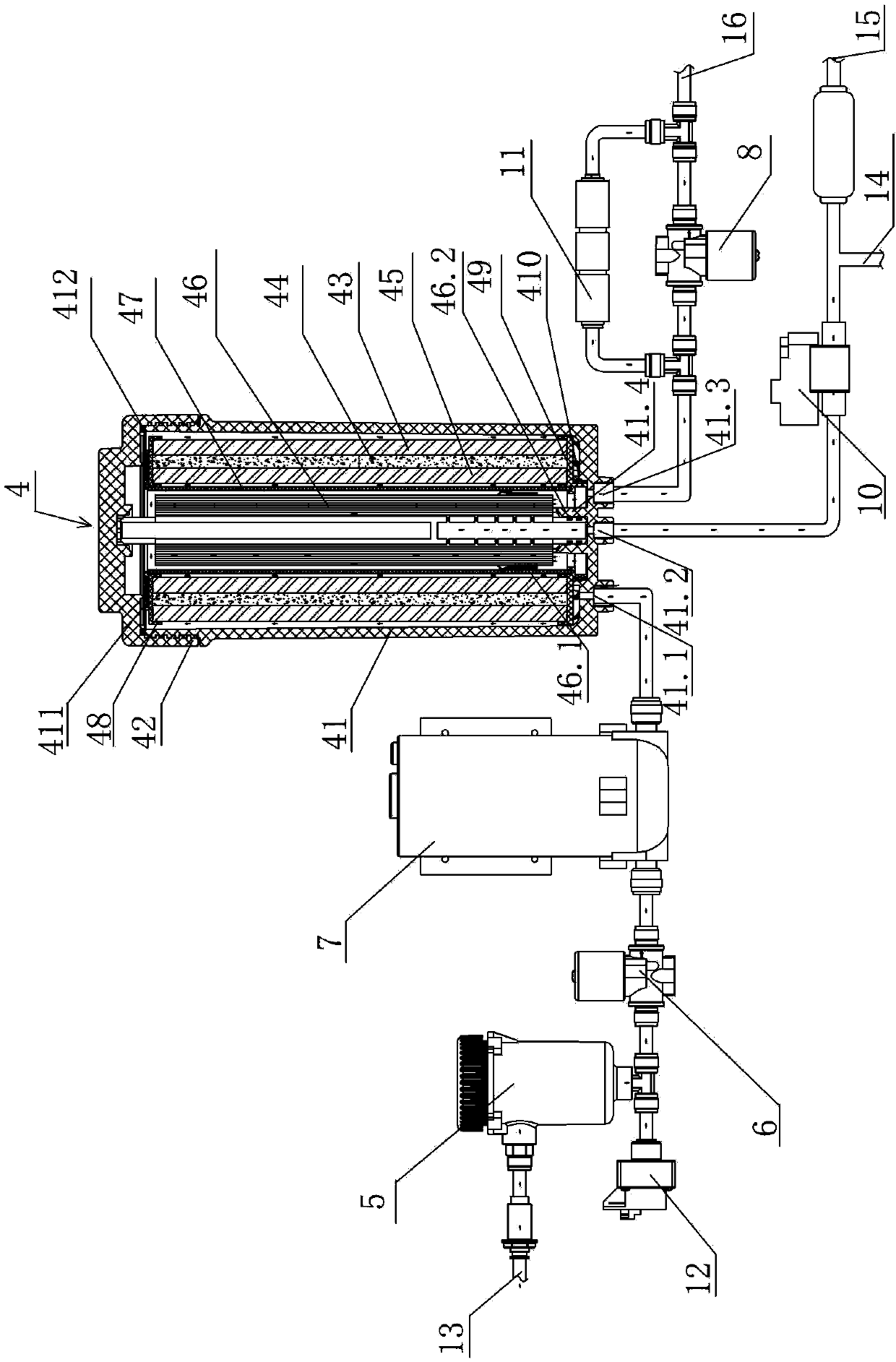

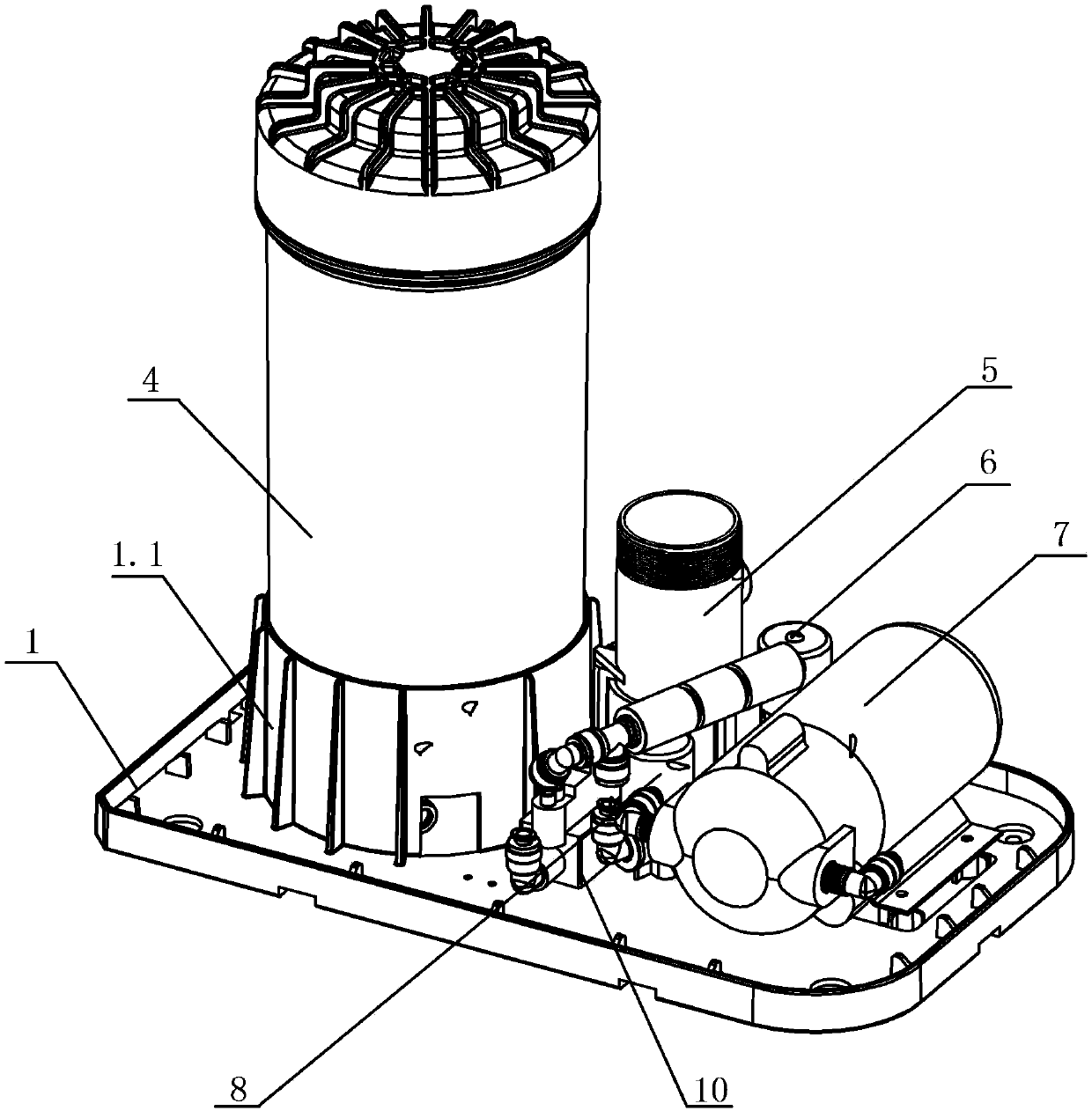

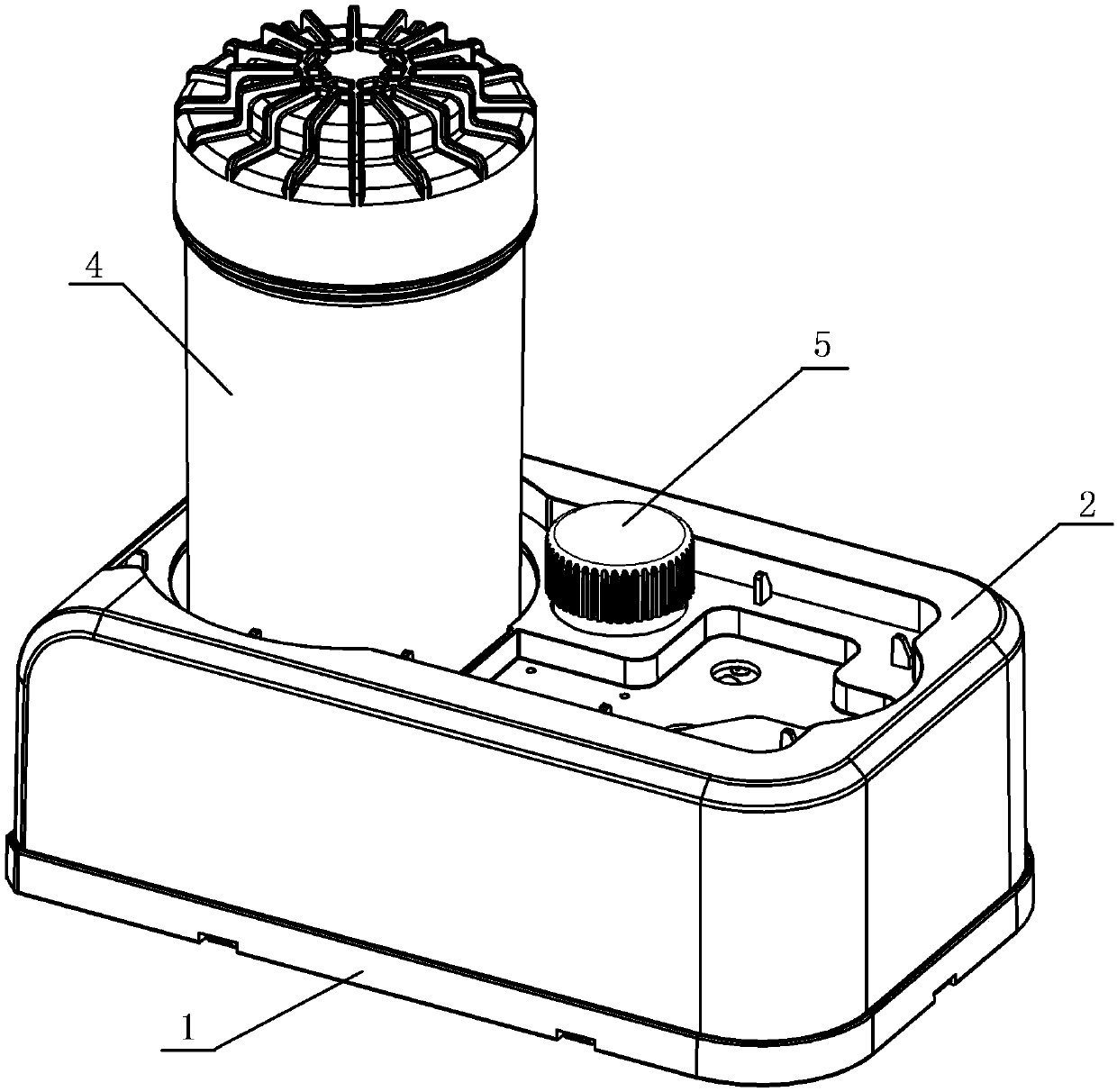

[0017] Such as Figure 1~5 As shown, the pure water machine of the present invention includes a housing, a front PP filter element 5 installed in the housing, a composite filter element 4, a rear filter element 9, a booster water pump 7, an inlet solenoid valve 6, a waste water solenoid valve 8, The high-voltage switch 10, low-voltage switch 12 and other components, the shell is composed of a base 1, a machine base 2 and a body 3, the machine base 2 is set on the base 1 and connected with the base 1 by a detachable reverse buckle, and the body 3 is set on the machine On the seat 2; the rear of the base 1 is provided with a protruding ring 1.1, and the protruding ring 1.1 is provided with a positioning groove for the bottom of the composite filter element 4 to be placed in, and the base 2 is provided with a hole for the head of the composite fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com