Tetraphenyl silicon-based blue light phosphorescent material and preparation method thereof and organic electroluminescent device

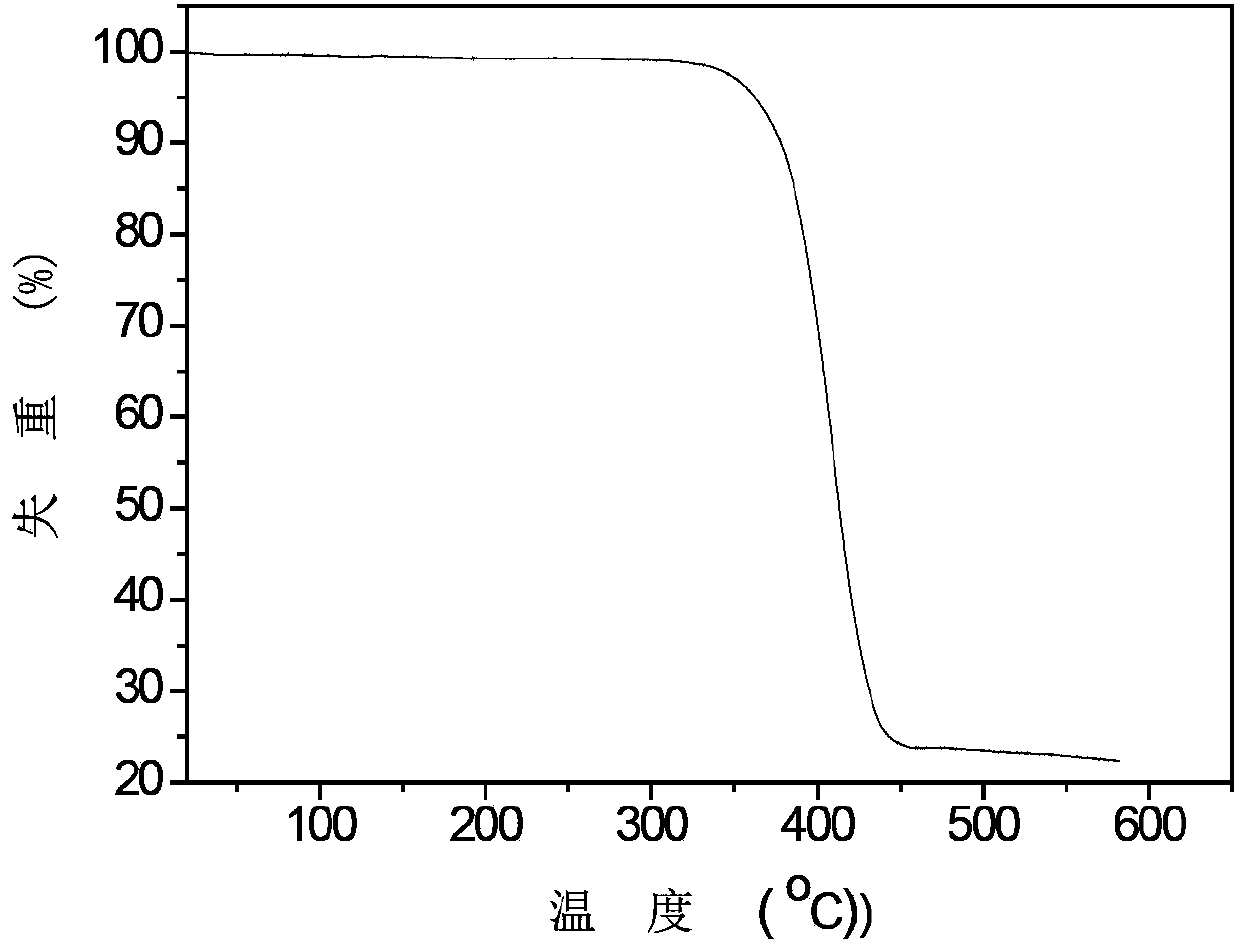

A technology of tetraphenyl silicon and phosphorescent materials, which is applied in the direction of luminescent materials, electric solid devices, organic chemistry, etc., can solve problems such as shortage, achieve good thermal stability, and improve luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

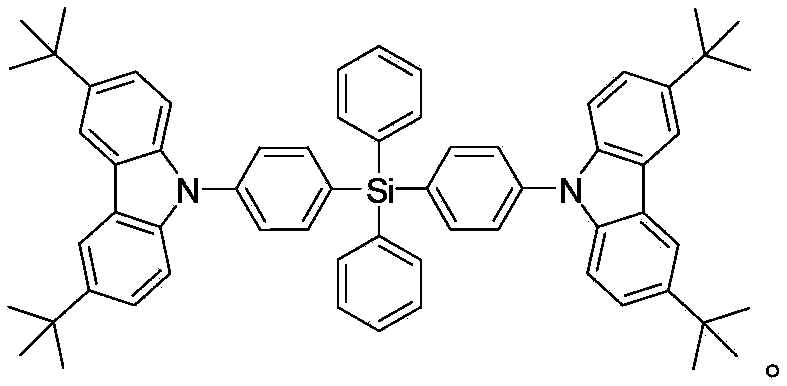

[0040] The tetraphenylsilicon-based blue-light phosphorescent compound of this embodiment, that is, bis(4-(3,6-di-tert-butyl-9H-carbazol-9-yl)phenyl)diphenylsilane, has the following structural formula:

[0041]

[0042] The preparation process of this compound is as follows:

[0043]

[0044] Under nitrogen protection, bis(4-bromophenyl)diphenylsilane (39.5g, 80mmol) was dissolved in 200mL N,N-dimethylformamide (DMF) solution, and then 3,6-di-tert-butyl Carbyl-9H-carbazole (44.7g, 160mmol), potassium carbonate (22.1g, 160mmol), cuprous iodide (1.52g, 8mmol). The mixture was stirred and reacted at 120°C for 6 hours. Stop the reaction and cool to room temperature, filter, and wash the solid three times with distilled water. The crude product is separated by silica gel column chromatography with eluent n-hexane, and then dried at 50°C for 24 hours under vacuum to obtain off-white solid bis(4-(3,6-di tert-Butyl-9H-carbazol-9-yl)phenyl)diphenylsilane. The yield was 79%. ...

Embodiment 2

[0047] The tetraphenylsilicon-based blue-light phosphorescent compound of this embodiment, that is, bis(4-(3,6-di-tert-butyl-9H-carbazol-9-yl)phenyl)diphenylsilane, has the following structural formula:

[0048]

[0049] The preparation process of this compound is as follows:

[0050]

[0051]Under nitrogen protection, bis(4-bromophenyl)diphenylsilane (39.5g, 80mmol) was dissolved in 200mL toluene (Tol) solution, and then 3,6-di-tert-butyl-9H-carbazole ( 49.1g, 176mmol), cesium carbonate (57.2g, 176mmol), copper powder (0.768g, 12mmol). The mixture was stirred and reacted at 110°C for 9 hours. Stop the reaction and cool to room temperature, filter, and wash the solid three times with distilled water. The crude product is separated by silica gel column chromatography with eluent n-hexane, and then dried at 50°C for 24 hours under vacuum to obtain off-white solid bis(4-(3,6-di tert-Butyl-9H-carbazol-9-yl)phenyl)diphenylsilane. The yield was 85%.

Embodiment 3

[0053] The tetraphenylsilicon-based blue-light phosphorescent compound of this embodiment, that is, bis(4-(3,6-di-tert-butyl-9H-carbazol-9-yl)phenyl)diphenylsilane, has the following structural formula:

[0054]

[0055] The preparation process of this compound is as follows:

[0056]

[0057] Under nitrogen protection, bis(4-bromophenyl)diphenylsilane (39.5g, 80mmol) was dissolved in 200mL acetonitrile (MeCN) solution, and then 3,6-di-tert-butyl-9H-carbazole ( 53.6g, 192mmol), potassium phosphate (39g, 184mmol), cuprous oxide (2.3g, 16mmol). The mixture was stirred and reacted at 90°C for 12 hours. Stop the reaction and cool to room temperature, filter, and wash the solid three times with distilled water. The crude product is separated by silica gel column chromatography with eluent n-hexane, and then dried at 50°C for 24 hours under vacuum to obtain off-white solid bis(4-(3,6-di tert-Butyl-9H-carbazol-9-yl)phenyl)diphenylsilane. The yield was 76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com