Tobacco hydrolat as well as preparation method and application thereof

A technology of tobacco and pure dew, applied in the direction of tobacco, application, treatment of tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

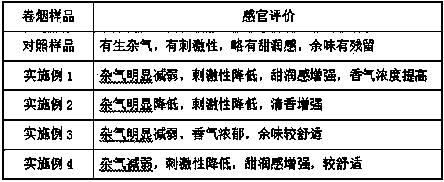

Examples

Embodiment 1

[0020] Put 60g of red flue-cured tobacco waste powder samples that have been dried and crushed through a 60 mesh sieve into a flask equipped with an oil-water separator and a water vapor diffusion distillation device, add deionized water in the flask, and by weight, water: smoke powder is 3.0: 1, add table salt to the flask, by weight, table salt: water is 0.5: 100, add zeolite of 1% of the total amount of the solution in the flask to the flask, shake and mix, soak for 2h. Turn on the heating mantle and heat to reflux for 8h. Cooling water control: When the flask is heated to an internal temperature of 60°C, turn on the condenser and turn on the cooling water. Within half an hour after boiling, use cooling water to control the temperature of the effluent cooled by the condenser at 20°C. After half an hour, The temperature of the effluent rose to 30°C and remained stable. Distillation control: After the effluent is separated by the oil-water separator, the water layer reflows ...

Embodiment 2

[0023] Put 60g dried and pulverized air-dried tobacco waste smoke powder samples into a flask equipped with an oil-water separator and a water vapor diffusion distillation device, and add deionized water in the flask. By weight, water: smoke powder is 2.0 : 1. Add table salt to the flask, by weight, table salt: water is 0.5: 100, add 2% zeolite of the total amount of solution in the flask to the flask, shake and mix and soak for 2h. Turn on the heating mantle and heat to reflux for 7h. Cooling water control: When the flask is heated to an internal temperature of 60°C, turn on the condenser, connect the cooling water, and within half an hour after boiling, use cooling water to control the temperature of the effluent cooled by the condenser at 22°C, after half an hour The temperature of the effluent rose to 32°C and remained stable. Distillation control: After the effluent is separated by the oil-water separator, the water layer reflows back into the flask. The reflow time is ...

Embodiment 3

[0026] Put 60g of oriental tobacco waste smoke powder samples dried and crushed through a 60 mesh sieve into a flask equipped with an oil-water separator and a water vapor diffusion distillation device, add deionized water in the flask, by weight, water: smoke powder is 2.0 : 1. Add table salt in the flask, by weight, table salt: water is 0.5: 100, add 3% zeolite of the total amount of the solution in the flask to the flask, shake and mix and soak for 2h. Turn on the heating mantle and heat to reflux for 6h. Control of cooling water: When the flask is heated to an internal temperature of 60°C, turn on the condenser, connect the cooling water, and within half an hour after boiling, use cooling water to control the temperature of the effluent cooled by the condenser at 24°C, and after half an hour The temperature of the effluent rose to 33°C and remained stable. Distillation control: After the effluent is separated by the oil-water separator, the water layer reflows back into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com