High-speed hydraulic reversing slide valve

A hydraulic and high-speed technology, applied in the field of hydraulic devices, can solve the problems of difficult processing of the valve core, easy heating of the electromagnet coil, thrust and limitation, etc., and achieve the effect of easy processing, manufacturing and assembly, and convenient digital control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and embodiments.

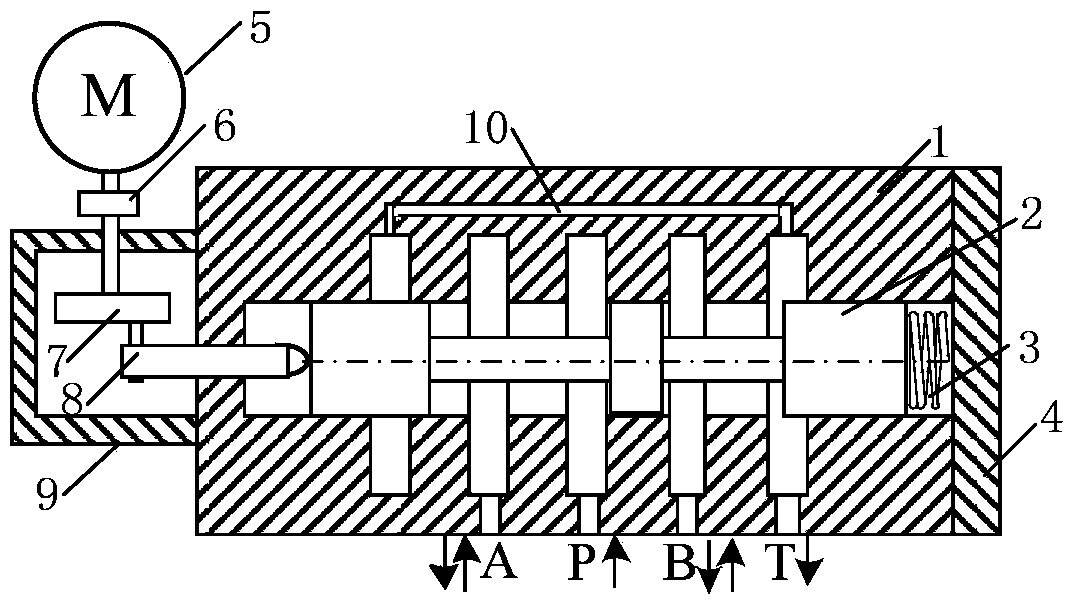

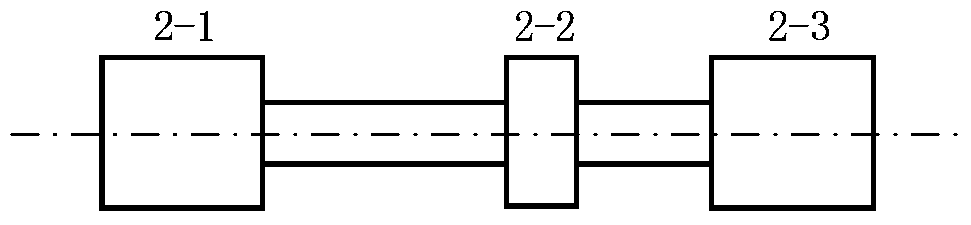

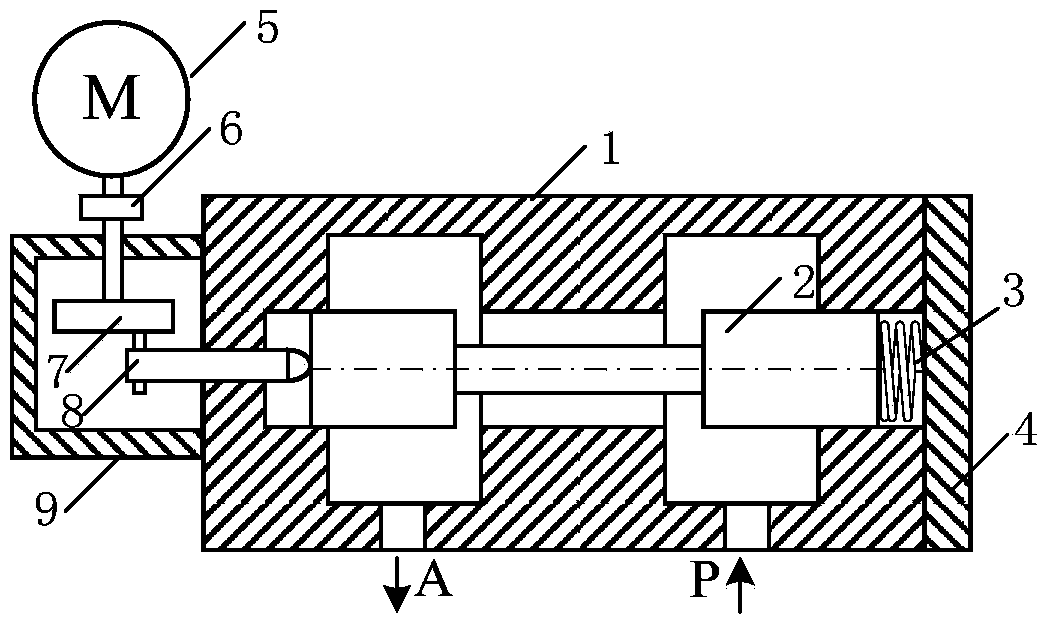

[0019] See figure 1 with figure 2 , The present invention includes a valve body 1, a slide valve core 2 arranged in the valve body 1, and a motor 5; the valve body 1 is provided with an oil inlet P, a first oil outlet A, a second oil outlet B, and an oil return Port T, the slide valve core 2 is provided with a first shoulder 2-1, a second shoulder 2-2, and a third shoulder 2-3 that are used to realize the connection or disconnection of each oil port under the cooperation of the push rod 8. . The valve body 1 is provided with a flow passage 10 for connecting the first oil outlet A and the oil return port T. A motor seat 9 for supporting the motor 5 is fixed on the end surface on one side of the valve body 1. The output shaft of the motor 5 is connected to the central axis of the upper end of the rotary disc 7 through a coupling 6, and the lower end of the rotary disc 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com