Convergence type hydraulic and mechanical continuously variable transmission provided with double planet rows

A technology of continuously variable transmission and double planetary row, applied in the direction of vehicle transmission, mechanical equipment, fluid transmission device, etc., can solve the problems of increasing the complexity of the mechanical structure of the transmission, unable to realize continuous transmission, and reducing the transmission performance of the vehicle, etc. Achieve the effect of smooth shifting and automatic adjustment of transmission ratio, reducing size and weight, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

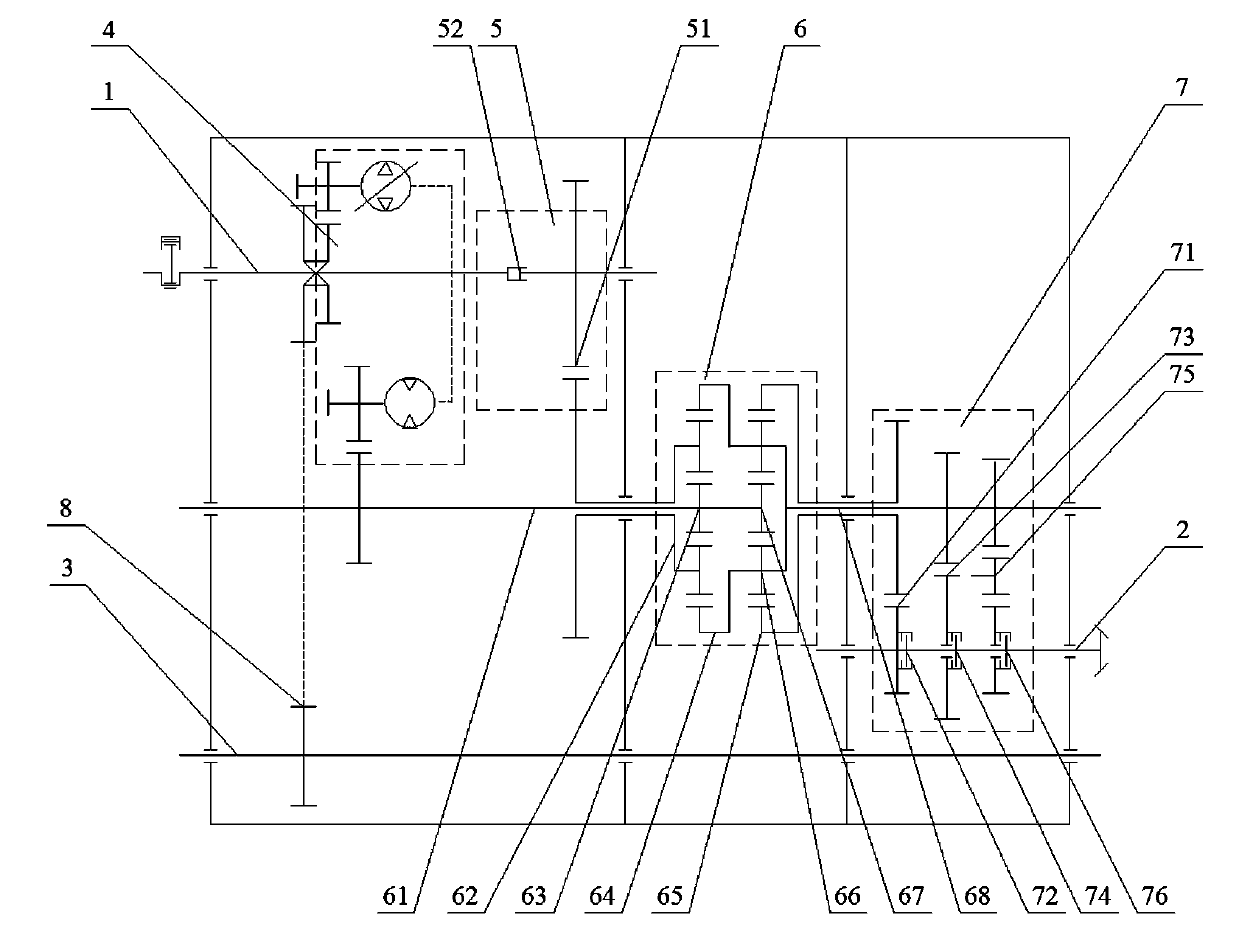

[0019] like figure 1 As shown, a double planetary row confluence hydraulic mechanical continuously variable transmission includes an input shaft 1, an output shaft 2, a power output shaft 3, a hydraulic transmission assembly 4, a mechanical transmission assembly 5, a double planetary row mechanism assembly 6, The shifting mechanism assembly 7 and the power output gear pair 8, the power input by the input shaft 1 respectively passes through the hydraulic transmission assembly 4 and the mechanical transmission assembly 5, and then merges through the double planetary mechanism assembly 6, and the merged power passes through The shift mechanism assembly 7 and the output shaft 2 output power; the input shaft 1 drives the power output shaft 3 to output power through the power output gear pair 8; it is characterized in that: the double planetary row mechanism assembly 6 includes a planetary row sun gear shaft 61, Front planetary row carrier 62, front planetary row sun gear 63, front ...

Embodiment 2

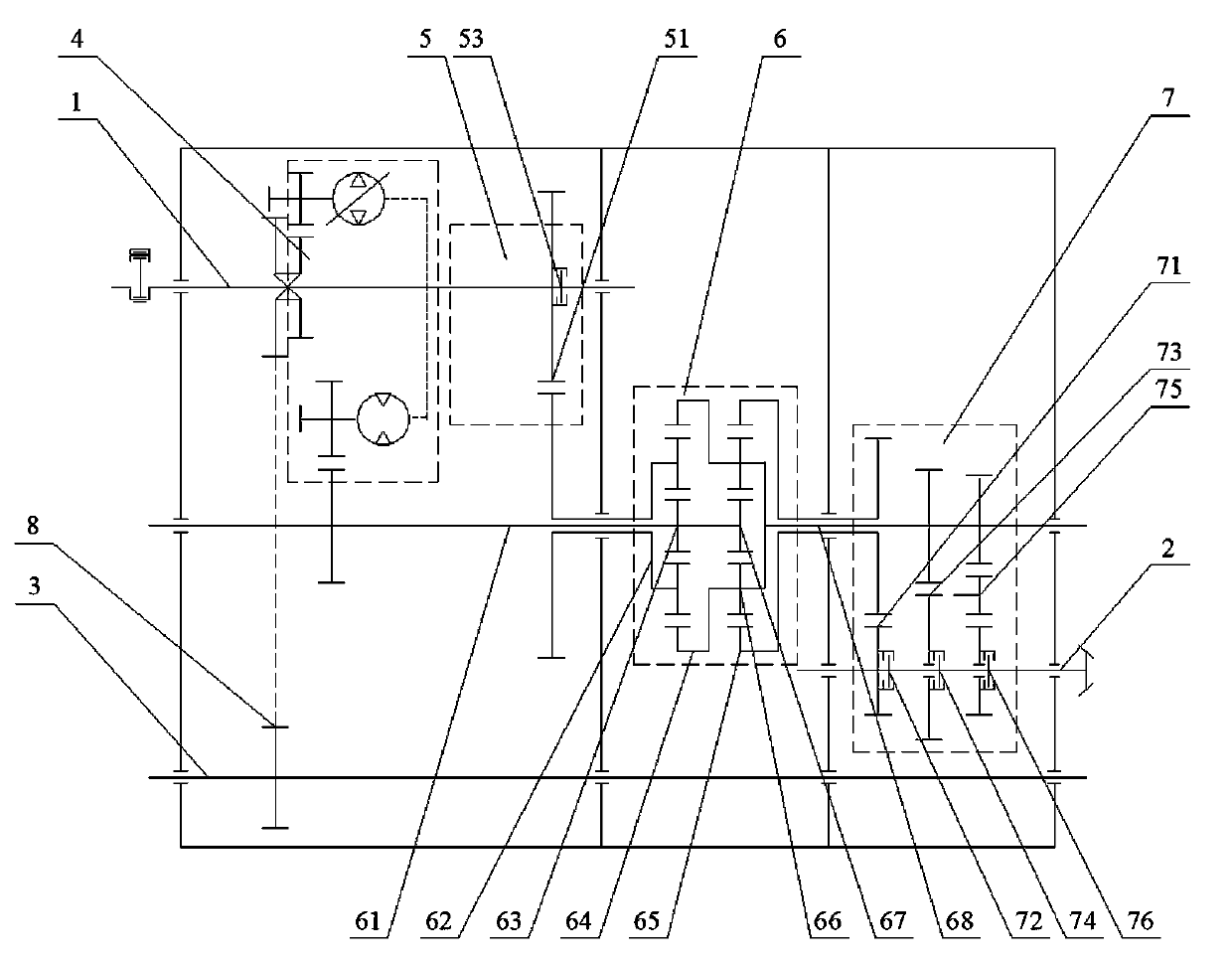

[0026] like figure 2 As shown, a double planetary row confluence hydraulic mechanical continuously variable transmission includes an input shaft 1, an output shaft 2, a power output shaft 3, a hydraulic transmission assembly 4, a mechanical transmission assembly 5, a double planetary row mechanism assembly 6, The shifting mechanism assembly 7 and the power output gear pair 8, the power input by the input shaft 1 respectively passes through the hydraulic transmission assembly 4 and the mechanical transmission assembly 5, and then merges through the double planetary mechanism assembly 6, and the merged power passes through The shift mechanism assembly 7 and the output shaft 2 output power; the input shaft 1 drives the power output shaft 3 to output power through the power output gear pair 8; it is characterized in that: the double planetary row mechanism assembly 6 includes a planetary row sun gear shaft 61, Front planetary row carrier 62, front planetary row sun gear 63, front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com