Air conditioner and water heater all-in-one machine

An air-conditioning hot water, all-in-one technology, applied in refrigerators, compressors, fluid heaters, etc., can solve the problems of increasing refrigerant flow resistance, inability to achieve end difference, small heat transfer area, etc., and achieve faster evaporation Speed and condensation speed, fast heat removal speed, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

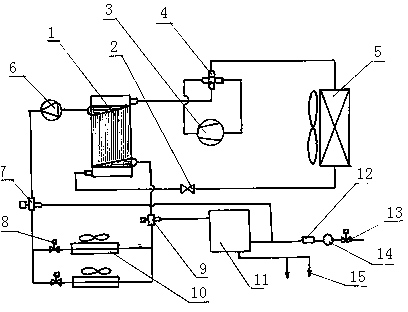

[0032] refer to figure 1 , this embodiment includes a plate-fin counterflow fine channel heat exchanger 1, a throttling device 2, a compressor 3, a four-way electronic valve 4, an air-side heat exchange device 5, a circulating pump 6, a three-way electronic valve I7, and an air conditioner terminal Electronic valve 8, three-way electronic valve II 9, air-conditioning terminal 10, hot water circulation tank 11 and water inlet electronic valve 13; the air-conditioning terminal 10 is composed of a fan and a pure countercurrent honeycomb plate-fin heat exchanger; the plate-fin The inlet of the fluid on one side of the type counterflow fine channel heat exchanger 1 is connected with the four-way electronic valve 4 through the pipeline, and the outlet is connected with the throttling device 2 through the pipeline, and the throttling device 2 exchanges heat with the air side through the pipeline The air-side heat exchange device 5 is connected to the four-way electronic valve 4 throu...

Embodiment 2

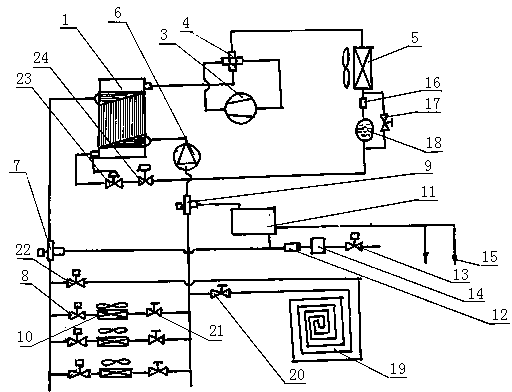

[0038] refer to figure 2 , this embodiment includes a plate-fin counterflow fine channel heat exchanger 1, a compressor 3, a four-way electronic valve 4, an air-side heat exchange device 5, a circulating pump 6, a three-way electronic valve I7, an air-conditioning terminal electronic valve 8, three Through electronic valve II9, air conditioner terminal 10, hot water circulation tank 11, water inlet electronic valve 13, check valve 16, bypass valve 17, liquid storage volume tank 18, floor heating circuit 19, floor heating circuit valve 20, air conditioner terminal circuit valve 21. Floor heating circuit water inlet electronic valve 22, temperature sensing electronic valve 23 and expansion valve 24; the air conditioner terminal 10 is composed of a fan and a pure counterflow honeycomb plate-fin heat exchanger; the plate-fin counterflow fine channel heat exchange The inlet of the fluid on one side of the device 1 is connected with the four-way electronic valve 4 through the pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com