High/low-temperature slide/roll tribological property experimental table

A tribology, high and low temperature technology, used in the field of test benches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

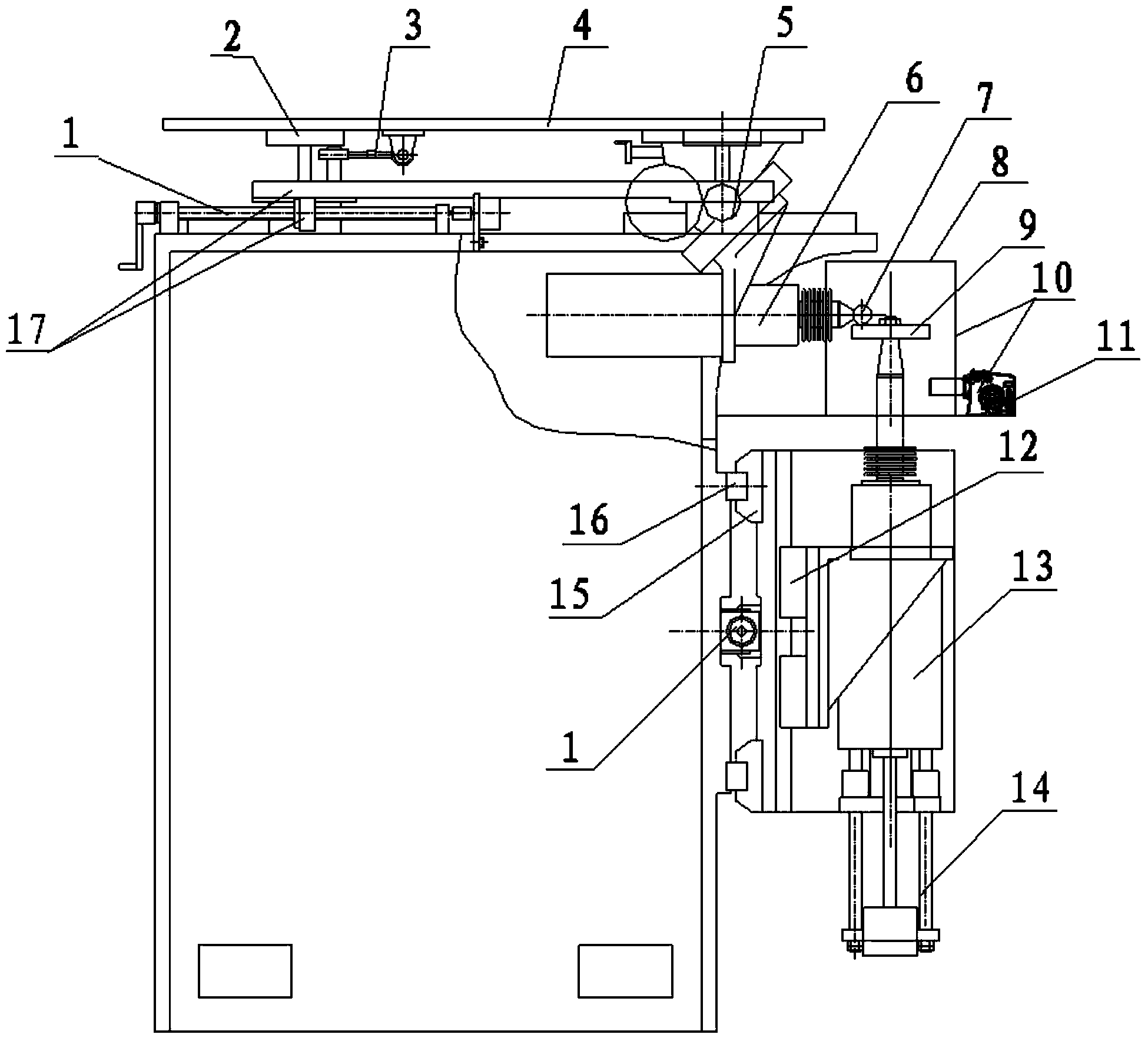

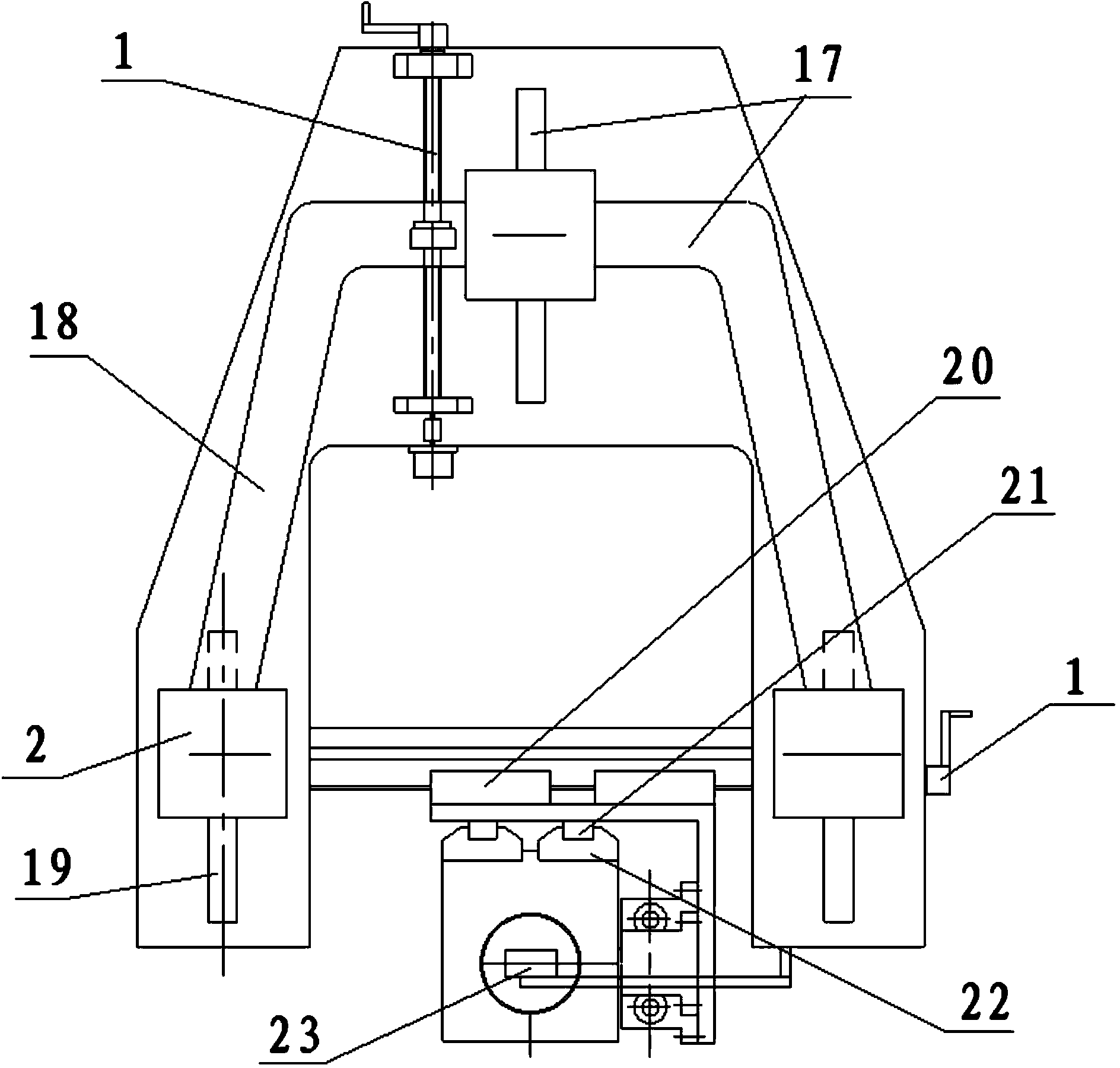

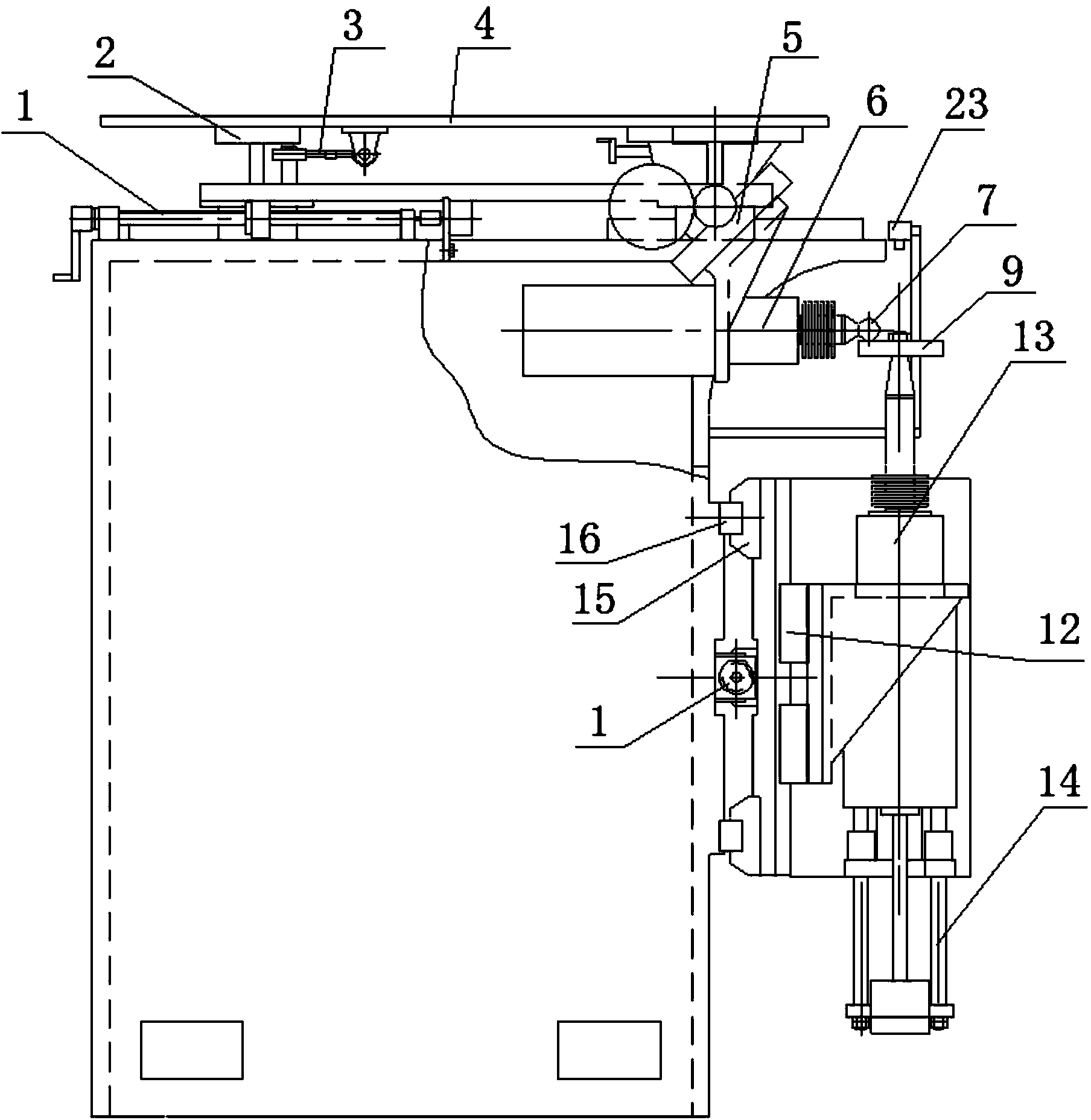

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The high and low temperature sliding and rolling tribological performance test bench includes a vertical electric spindle 13, an inclined electric spindle 6, an upper cover plate 4, an air bearing 2, a force measuring structure 3, a temperature control device 10, a speed sensor and a pressure sensor; an upper cover plate 4 It is set horizontally and supported by the air bearing 2; the lower part of the upper cover plate 4 is connected with the inclined electric spindle 6, and the end of the inclined electric spindle 6 is connected with a spherical or roller-shaped first test piece 7; the vertical electric spindle 13 is connected with a The disc-shaped second test piece 9; the first test piece 7 is in contact with the surface of the second test piece 9; the force-measuring structure 3 measures the horizontal force transmitted from the tilt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com