Graphene transparent conductive film

A transparent conductive film, transparent conductive technology, applied to the conductive layer on the insulating carrier, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of limited adhesion of transparent substrates, unsatisfactory conductivity, etc., to achieve expansion Range, optimum sheet resistance value, effect of reducing sheet resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in more detail below in conjunction with the drawings and component symbols, so that those skilled in the art can implement it by referring to the description.

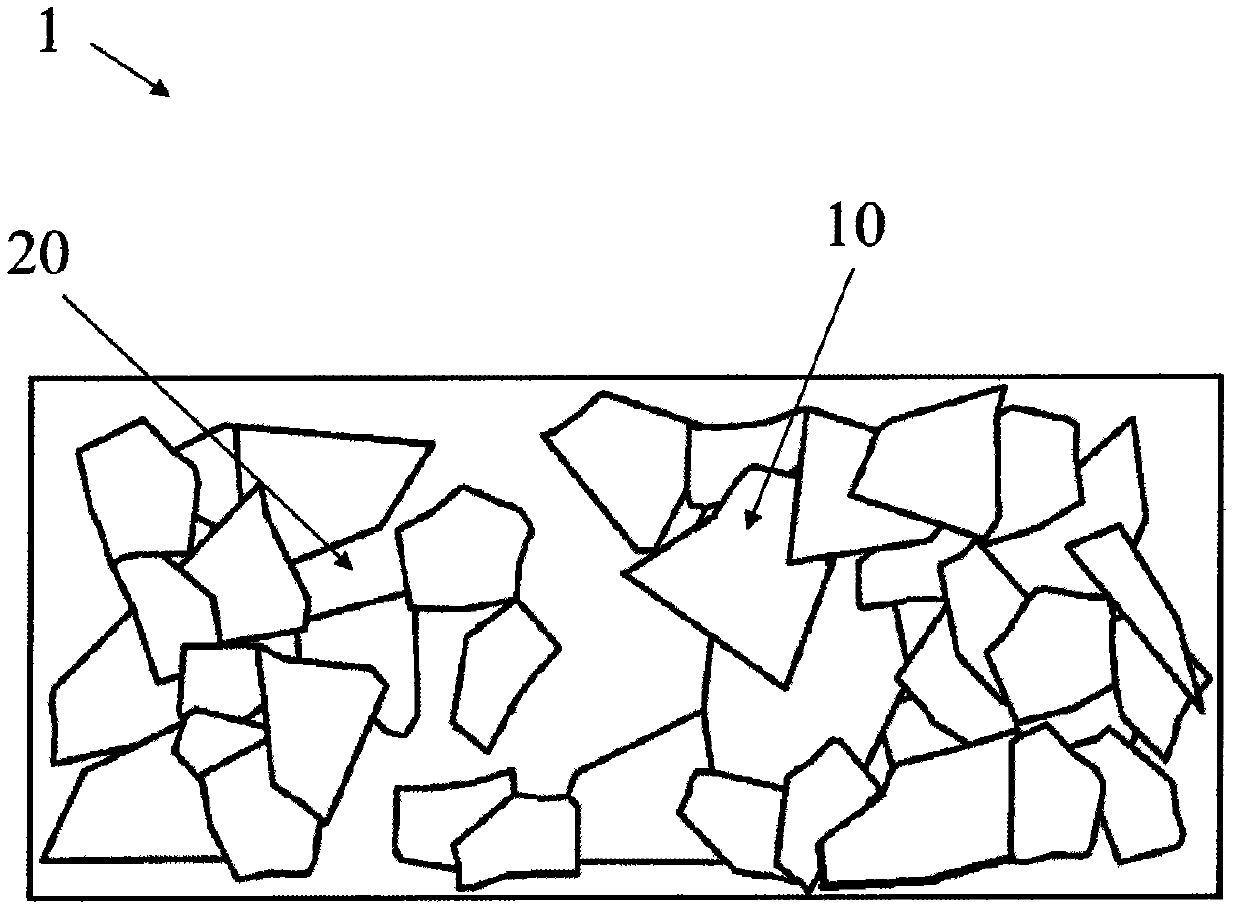

[0019] refer to figure 1 , figure 1 It is a schematic diagram of the microstructure of the graphene transparent conductive film of the present invention. like figure 1 As shown, the graphene transparent conductive film 1 of the present invention comprises a plurality of graphene sheets 10, and a transparent conductive adhesive 20, and the transparent conductive adhesive 20 bonds the graphene sheets 10 to jointly form the graphene transparent conductive film 10. The film 1, the graphene transparent conductive film 1 can be attached on a support (not shown), wherein the weight ratio of the graphene sheet 10 to the transparent conductive adhesive 20 is between 1wt% and 0.01wt%. The transparent conductive adhesive 20 accounts for 0.5%-10% by volume of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com