Structure for lowering linear polarization laser pulse repetition frequency and improving pulse energy

A laser pulse and repetition frequency technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of doubling, unable to achieve repetition frequency, and reduce pulse energy, so as to improve utilization efficiency, reduce repetition frequency, improve The effect of pulse energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

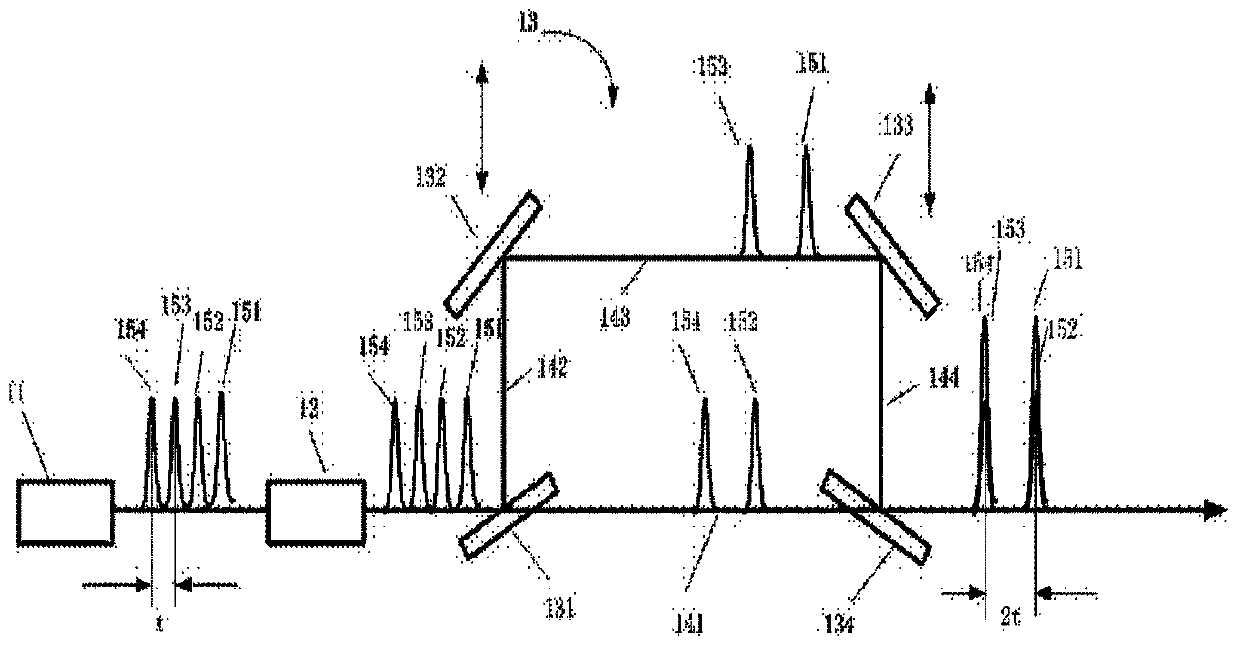

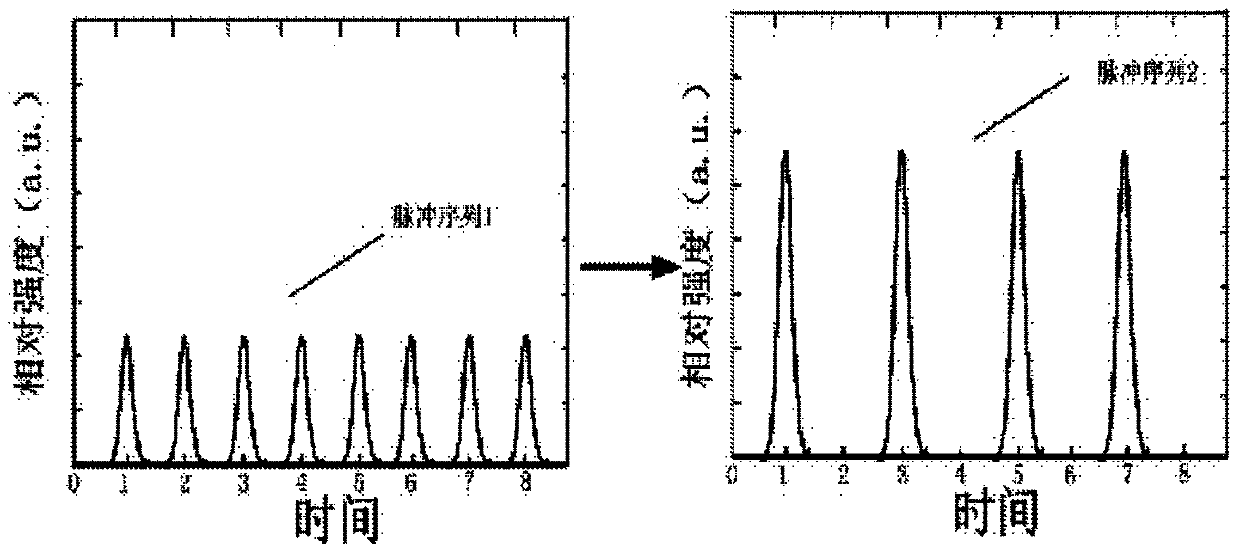

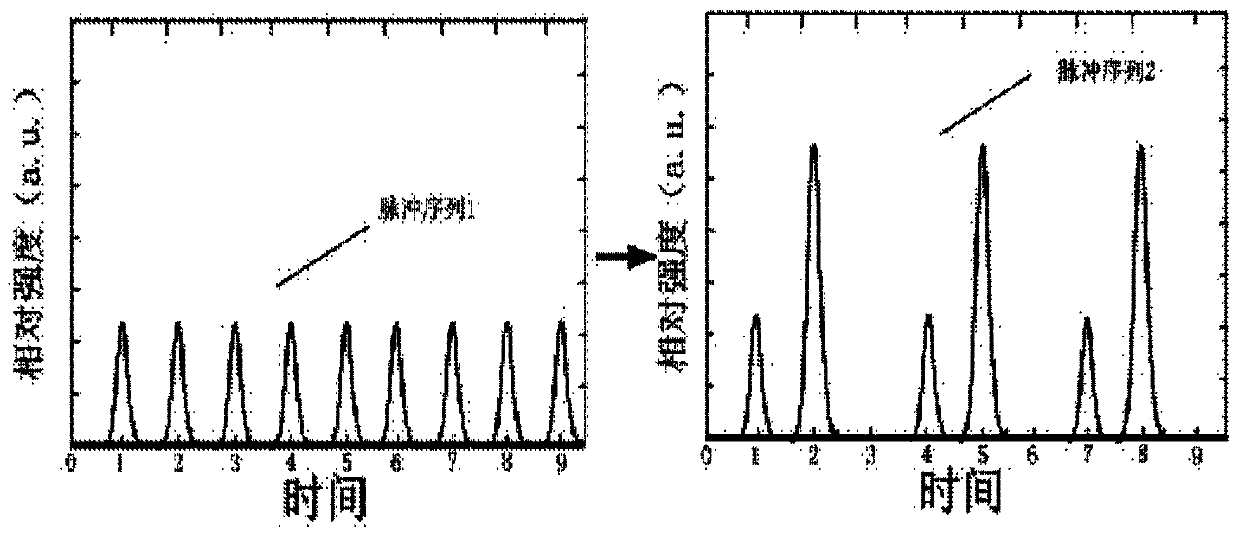

[0017] see figure 1 As shown, the present invention provides a structure that reduces the repetition rate of linearly polarized laser pulses and improves the pulse energy, including:

[0018] A linearly polarized pulsed laser source 11 is used to emit linearly polarized pulsed laser light. The linearly polarized pulsed laser source 11 is a continuous wave chopper laser source, a Q-switched laser source or a mode-locked pulsed laser source. The output laser pulse range is Covering milliseconds, microseconds, nanoseconds, picoseconds, and femtoseconds, the output light polarization state of the pulsed laser source 11 is linearly polarized light, and the pulse repetition frequency is single and fixed, and the time interval t between two adjacent pulses is also fixed of;

[0019] The linearly polarized pulsed laser source 11 is a picosecond pulsed laser with a repetition rate of 100 MHz, an output power of 50 W, a wavelength of 1064 nm, an interval of two pulses of 10 ns, a pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com