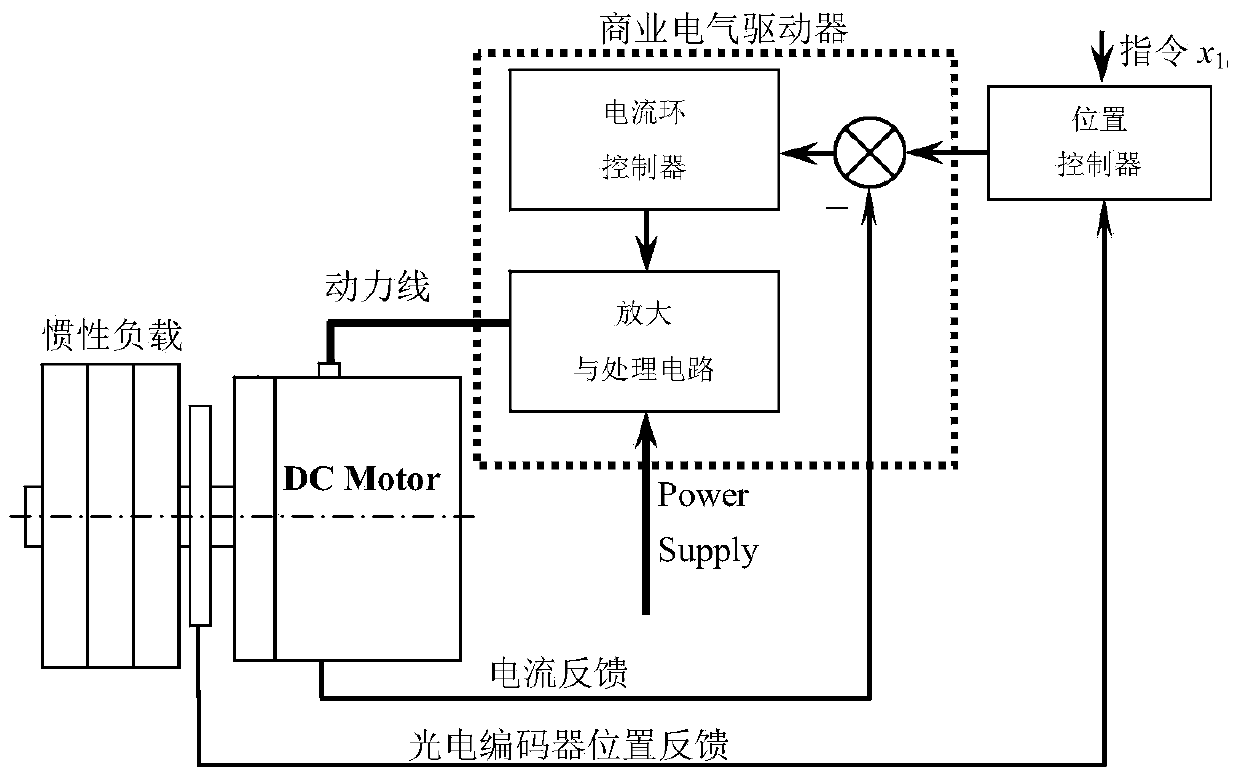

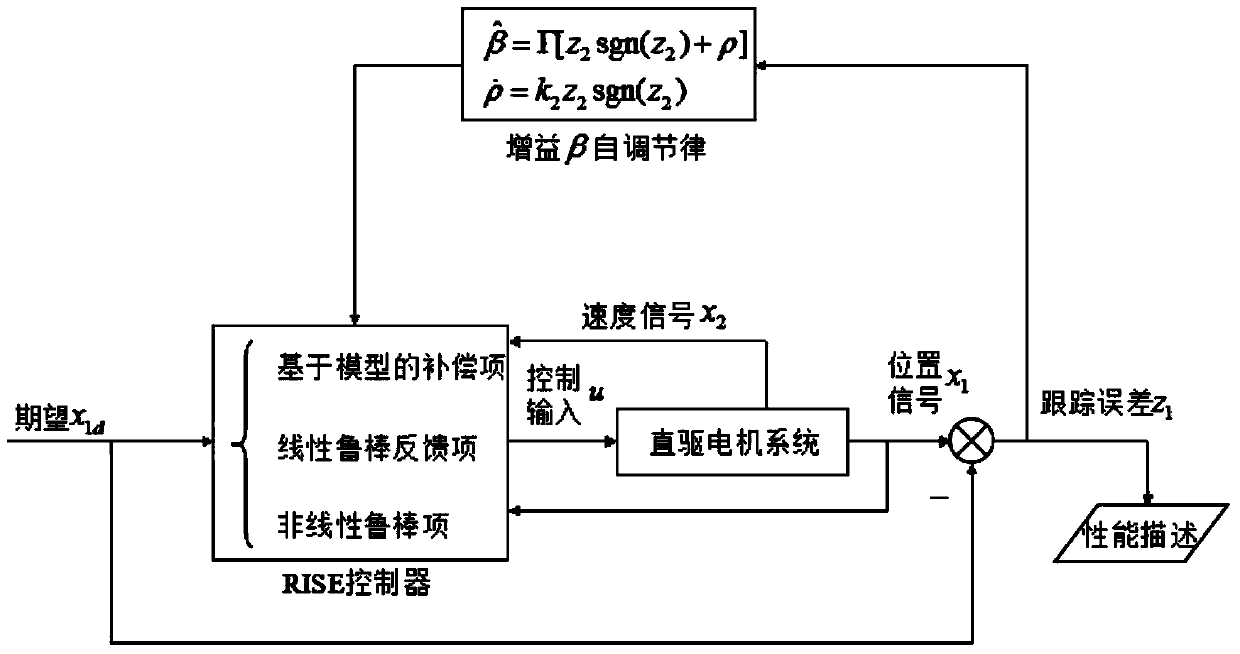

Self-regulating error symbol integration robust control method for direct-drive motor system

A technology of direct drive motor and error sign, which is applied in the field of self-adjusting error sign integral robust control of direct drive motor system, can solve problems such as sliding mode surface flutter, difficult time acquisition, and deterioration of system tracking performance, so as to solve random performance, good tracking performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

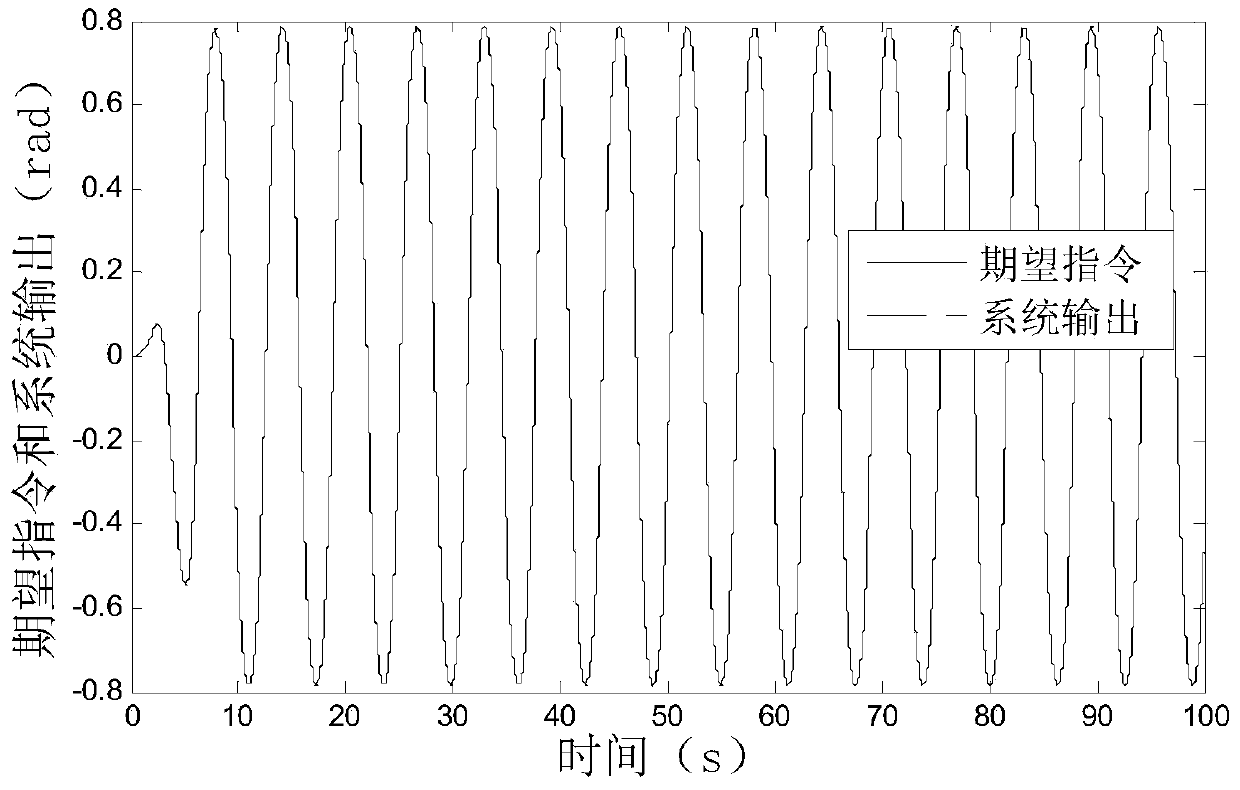

[0100] In order to assess the performance of the designed controller, the following parameters are taken in the simulation to model the direct drive motor system:

[0101] Inertia load parameter m=0.02kg·m 2 ; Viscous friction coefficient B = 10N m s / rad; torque amplification factor k i =5N·m / V;

[0102] The desired instruction for a given system is x 1d =sin(t)[1-exp(-0.01t 3 )] (rad).

[0103] According to two different system working conditions, the simulation process is divided into two parts:

[0104] ①When the time-varying interference f(t)=10sint(N·m)

[0105] Take the following controller for comparison:

[0106] Self-regulating error sign integral robust (ARISE) controller: take the controller parameter k 1 =10,k 2 = 1,k r = 1; The self-regulating law gain Γ=50.

[0107] PID controller: The selection steps of PID controller parameters are as follows: first, under the condition of ignoring the nonlinear dynamics of the direct drive motor system, a set of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com