Efficient environmental-friendly filter element and filter material thereof

An environmental protection and filter element technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that the air cannot meet the standard discharge, the dust removal and filtration effect is not good, and the air dust removal ability is weak, etc., to improve the air passing through Sexuality, simple structure, and the effect of reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

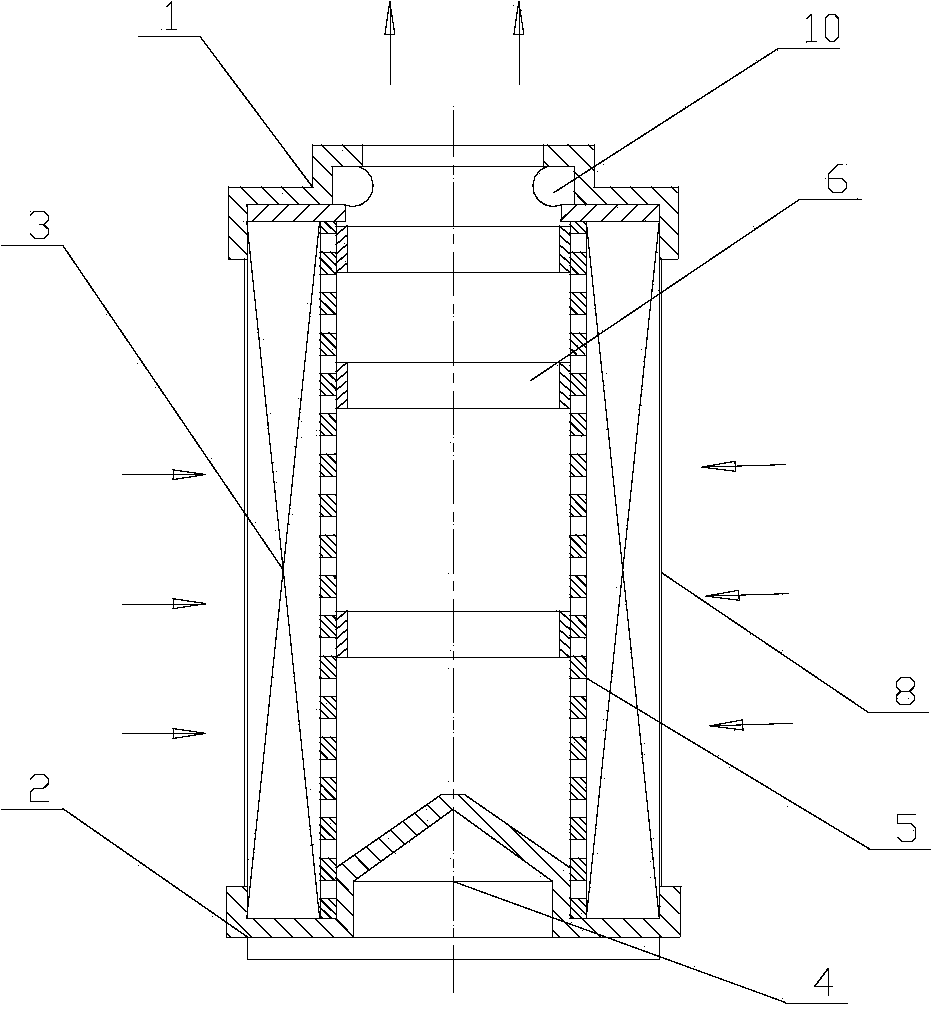

[0019] This embodiment provides a high-efficiency environmental protection filter element, the structure is as follows figure 1 As shown, it includes an upper end cover 1, a lower end cover 2 and a filter material 3 arranged between the upper end cover and the lower end cover. There is a conical cylinder 4, the outer side of the conical cylinder is fixedly connected with a cylindrical frame 5 made of metal mesh, the upper end of the cylindrical frame is fixedly connected with the ring inner hole of the upper end cover, and there are three rings Shaped support frame 6; filter material 3 is provided on the outer side of cylindrical frame 5, and wire mesh 8 is fixedly connected with the outer edge of upper end cover and lower end cover 2 on the outer side of filter material, and upper end cover 1 is connected with cylindrical frame 5 A sealing rubber ring 10 is provided at the place.

[0020] The filter material used for the high-efficiency environmental protection filter elemen...

Embodiment 2

[0026] The structure of the filter core of this embodiment is roughly the same as that of Embodiment 1, the difference is that the structure of the filter material of this embodiment differs from that of Embodiment 1 in that: the filter material is sequentially provided with a surface covering layer and an adsorption layer from outside to inside , support layer and bottom cover layer;

[0027] The surface covering layer is polypropylene thermal sprayed fiber membrane;

[0028] The adsorption layer is made of fiber blend, and its composition is made according to the following parts by weight: 27 parts of wood fiber, 7 parts of ceramic fiber, 13 parts of carbon fiber, and 30 parts of glass softening fiber;

[0029] The support layer is filled with coconut palm silk;

[0030] The bottom cover layer is a non-woven fabric with an average flow pore size of 65 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com