Device and method for uniformly mixing scattered fine powder

A uniform mixing and fine powder technology, which is applied in the field of material mixing devices and fine powder dispersion uniform mixing devices, can solve the problems of harsh working environment, pipeline blockage, mixing dead angle, etc., and achieve optimal operating conditions and Effect of working environment, preventing pipeline blockage and avoiding dead angle problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

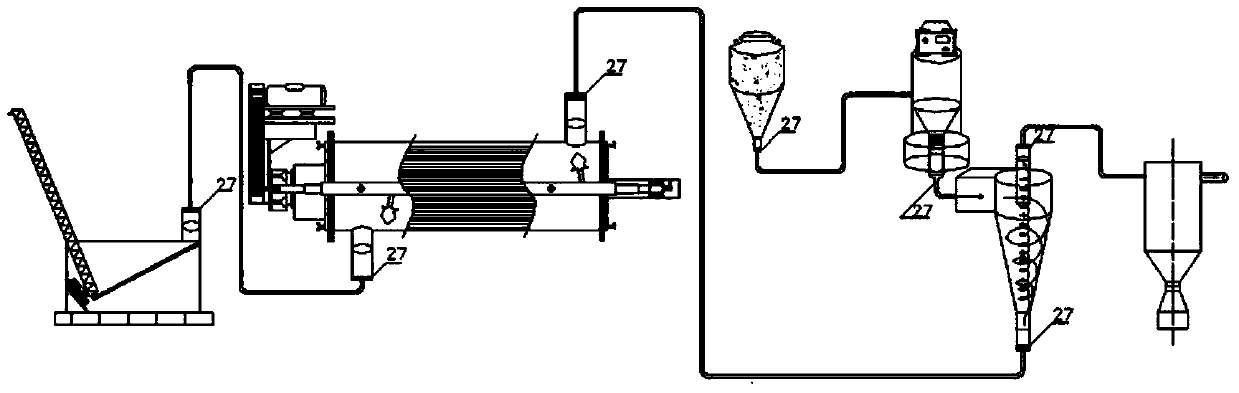

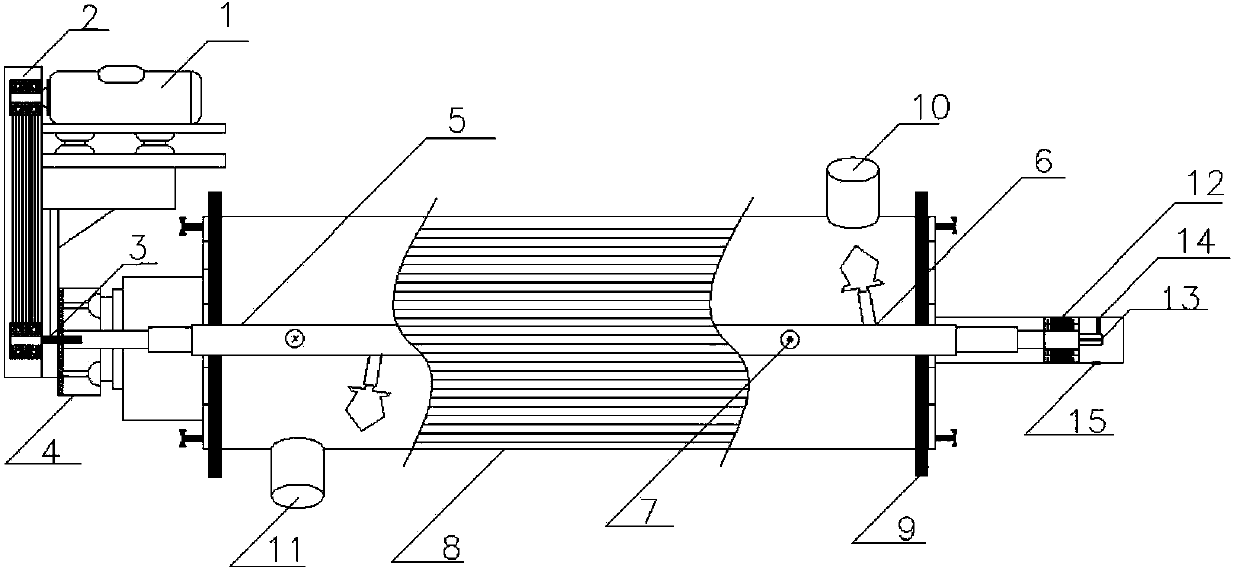

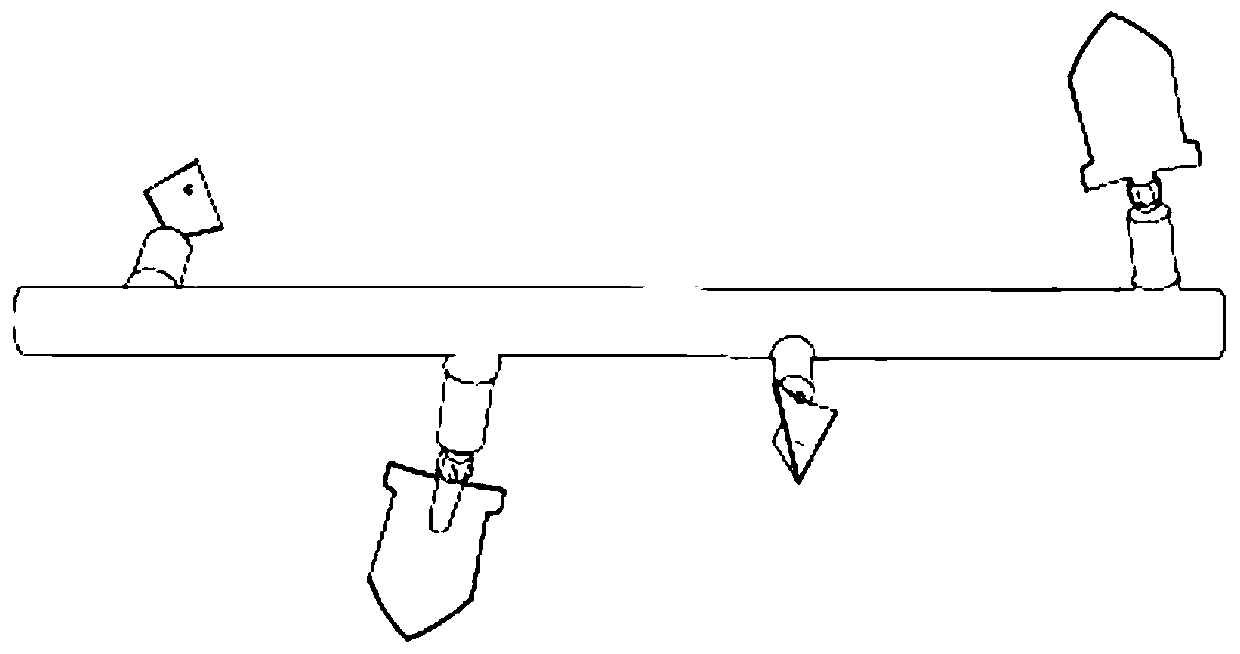

[0031] In order to further understand the uniform mixing device and method of the fine powder dispersion, the description is as follows in conjunction with the accompanying drawings.

[0032] It includes: a feeding device, a dust collector, a screw discharging device and a continuous discharging mixer; the feeding device includes: a storage tank 16, a radio frequency vacuum generator 19, a collection bin 20 and a cyclone separator 22; The radio frequency vacuum generator 19 is located at the top of the collection bin 20, the storage tank 16 is connected to one side of the collection bin 20 with a hose 18, and the other side of the collection bin 20 is connected to the cyclone separator 22 with a hose; the cyclone The separator 22 includes an inner cylinder 24 and an outer cylinder 23, the inner cylinder 24 is placed above the outer cylinder 23 and inserted into the outer cylinder 23; the upper end of the inner cylinder 24 is connected with the dust collector 25 through a hose 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com