Self-driven rasping machine

A self-driven, filing technology, applied in the field of filing machines, can solve problems such as the impact of transmission efficiency, high processing costs, and wear of transmission belts, and achieve the effects of improving transmission efficiency, simplifying structure, and reducing intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with accompanying drawing:

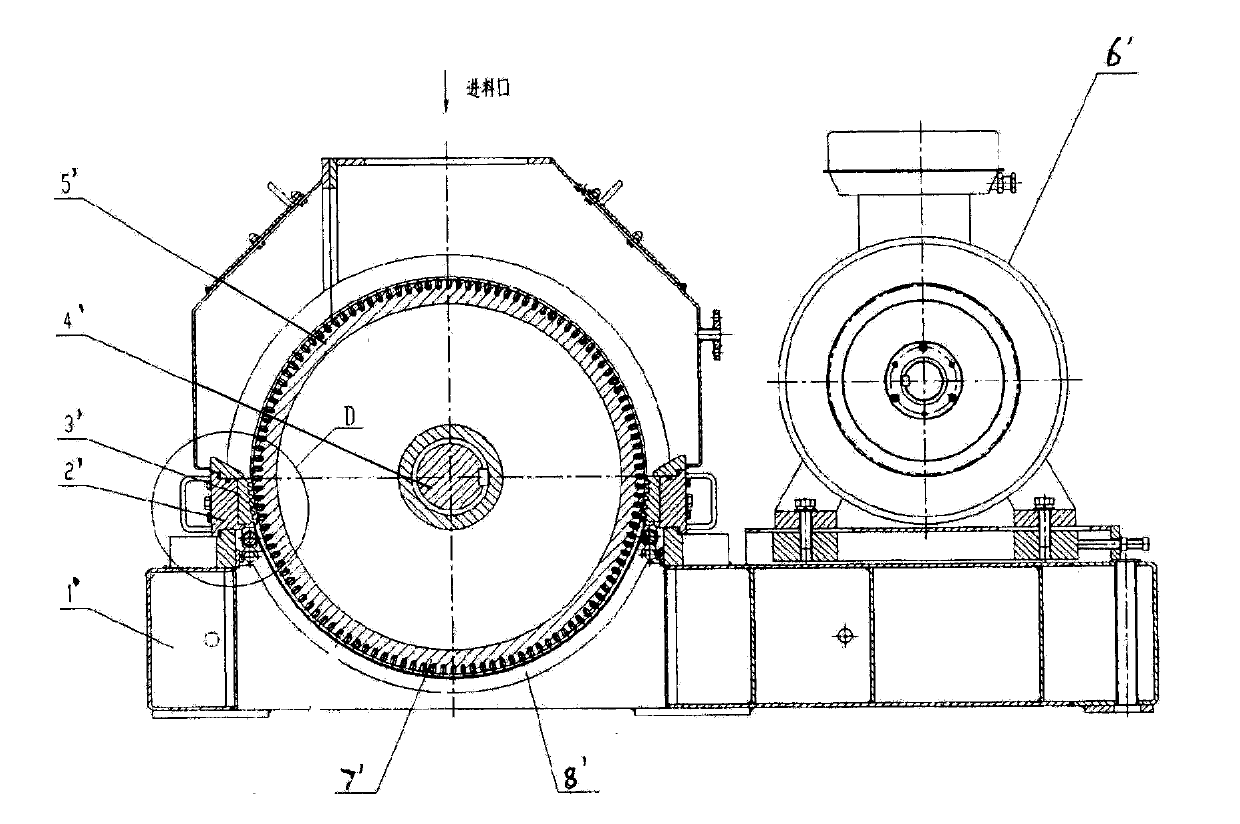

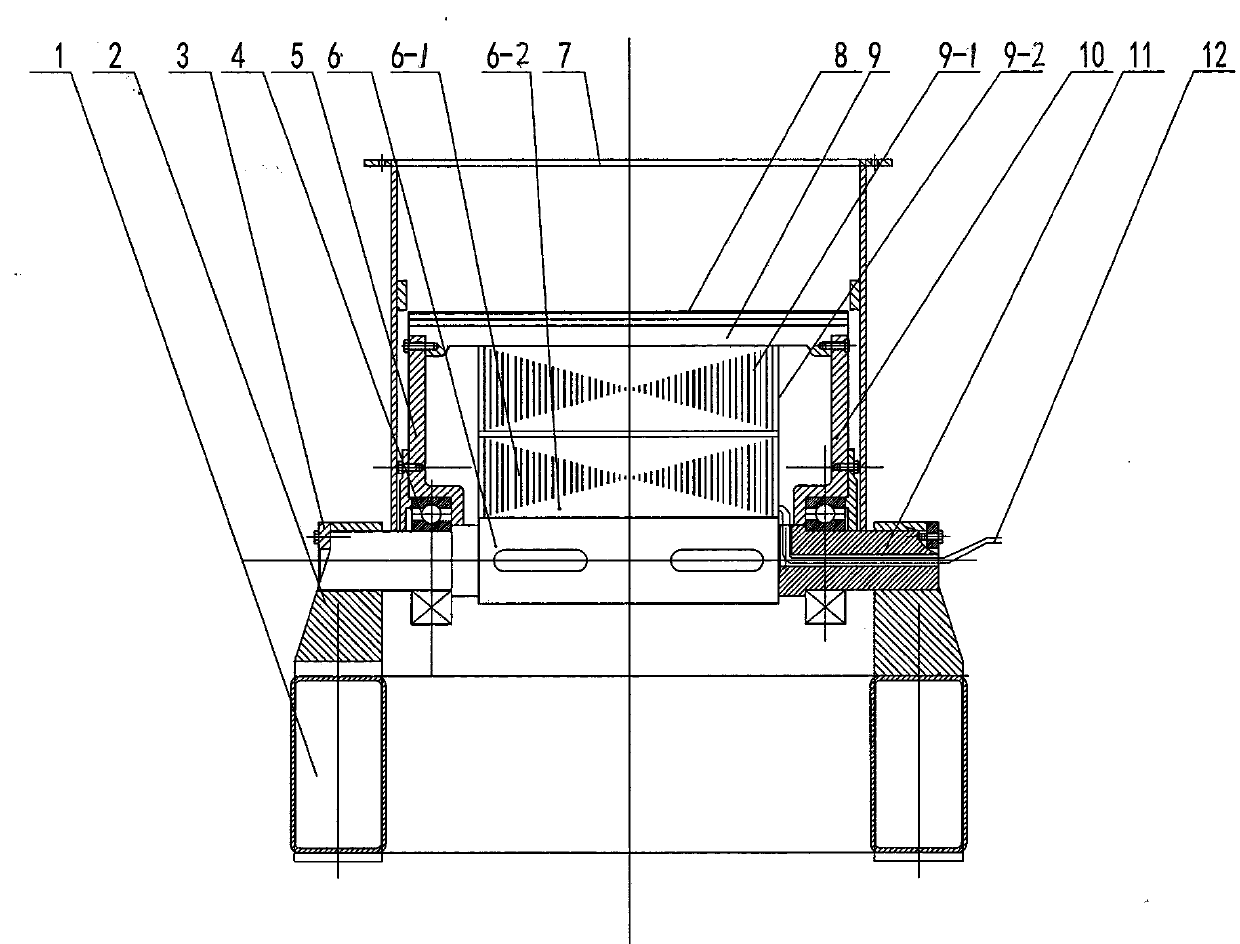

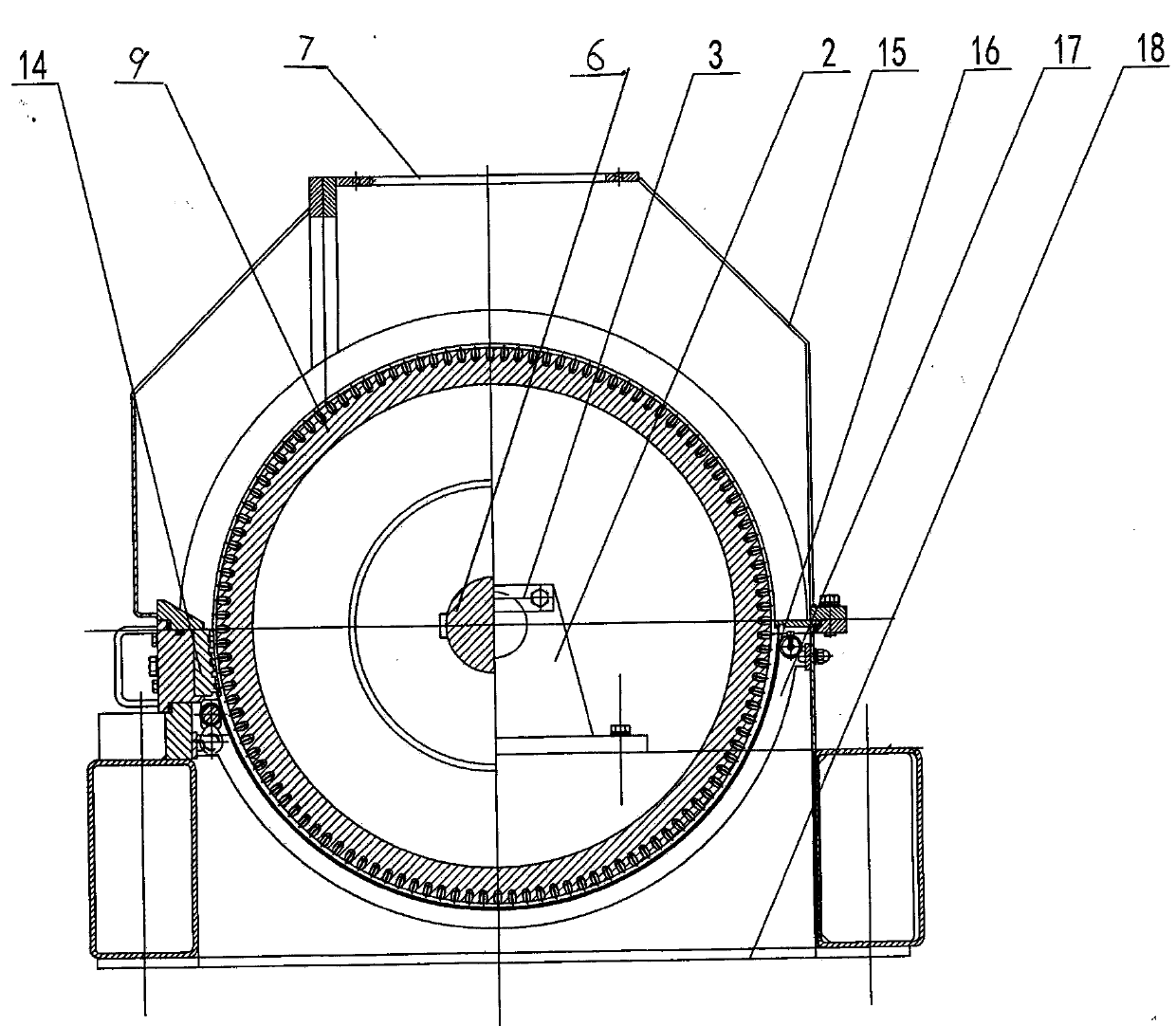

[0025] Such as figure 2 , 3 , 4, and 5 show: a self-driven filing machine, including a frame 15, a crushing chamber installed on the frame, a drum 9 arranged in the crushing chamber, and a screen 16 located below the drum. There is a filing saw blade 8, which forms a filing assembly with a filing plate 14 arranged on one side wall of the drum crushing chamber, wherein: the drum 9 is a cylindrical hollow tube structure, and the drum is set on the On a fixed shaft 6, the fixed shaft 6 is placed on the support seat 3 installed on the machine base 1, and the rotor assembly composed of the rotor core 9-1 and the rotor winding coil 9-2 is fixed on the inner wall of the drum 9 , a stator assembly composed of a stator core 6-1 and a stator winding coil 6-2 matching the rotor assembly is fixedly arranged on the fixed shaft 6, and there is a certain gap (0.2-2 mm) between the stator as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com