Microwave sintering method for hard alloy

A microwave sintering and cemented carbide technology, which is applied in the field of fine-grained cemented carbide and low cobalt content, can solve the problems of complex process, failure to achieve a good degree of cooperation, high cost, etc., and achieve the effect of firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

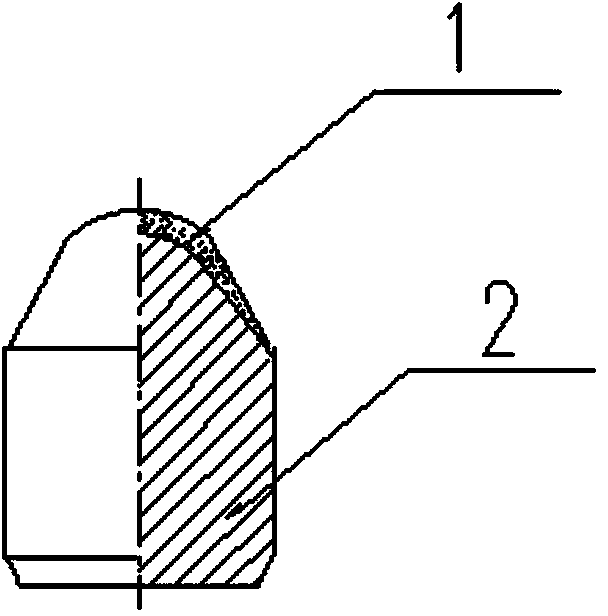

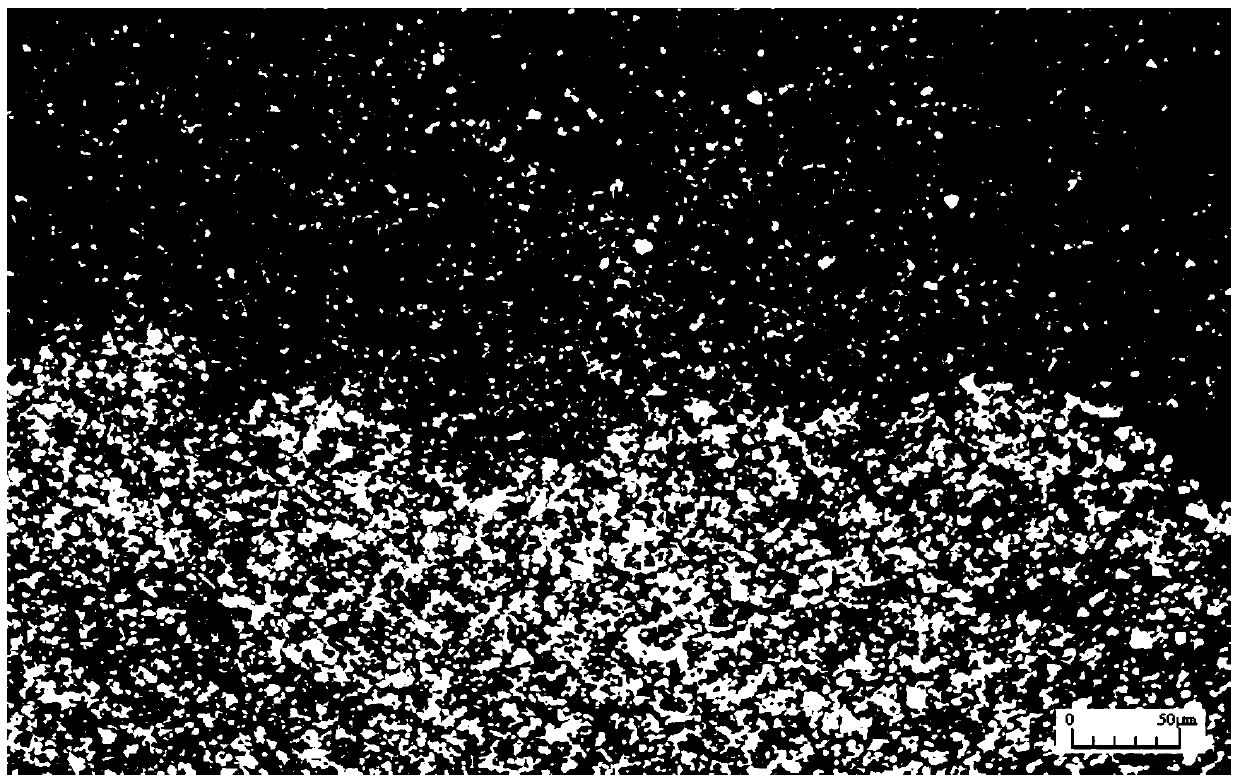

[0027] The surface layer of hard alloy on the tip of the tooth contains 5% cobalt, and the rest is composed of tungsten carbide and a very small amount of unavoidable impurities. The particle size of tungsten carbide is 0.8μm; the matrix cemented carbide contains 10% cobalt, and the rest is tungsten carbide and a very small amount of unavoidable impurities. The particle size of tungsten carbide is 1μm, 2μm and 3μm respectively, and its weight ratio is: 1μm: 2μm: 3μm = 30%: 30%: 40%. After powder mixing, the two powders are ball milled, dealcoholized, glued, and granulated , Pressed into a tapered tooth blank with a composite layer, the thickness of the surface layer is controlled within 1-5mm, and then microwave sintered. The process is a three-stage continuous sintering process: three stages of degreasing, redox and final densification are carried out continuously. The control conditions of the degreasing stage are: nitrogen protection, pressure: 3*10 3 ~20Pa; heating rate:...

Embodiment 2

[0029] The surface layer of cemented carbide on the tooth tip contains 6% cobalt, and the rest is composed of tungsten carbide and a very small amount of unavoidable impurities. The particle size of tungsten carbide is 0.7μm; the matrix cemented carbide contains 7% cobalt, and the rest is tungsten carbide and a very small amount of unavoidable impurities. The particle sizes of tungsten carbide are 1μm, 2μm and 3μm respectively, and the weight ratio is: 1μm:2μm:3μm=30%:30%:40%. After powder mixing, the two powders are ball milled, dealcoholized, glued, and granulated , Pressed into a tapered tooth blank with a composite layer, the thickness of the surface layer is controlled within 1-5mm, degreased in a degreasing furnace, and then microwave sintered. The process is as follows: nitrogen gas protection, pressure: 3*10 3 ~20Pa; heating rate: 15°C / min, from room temperature to 550°C; heat preservation at 550°C for 10 minutes; then heat up to 1080°C at a rate of 15°C / min; heat pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com