Cutting device and method for bearing steel tube

A technology for cutting devices and bearing steel pipes, which is applied in the direction of pipe shearing devices, shearing devices, maintenance and safety accessories, etc., can solve the problems of limiting the use range of cutting devices, easy deformation of the incision, and complex overall structure, so as to avoid further dangers Expansion, disassembly, assembly, maintenance and replacement are convenient, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

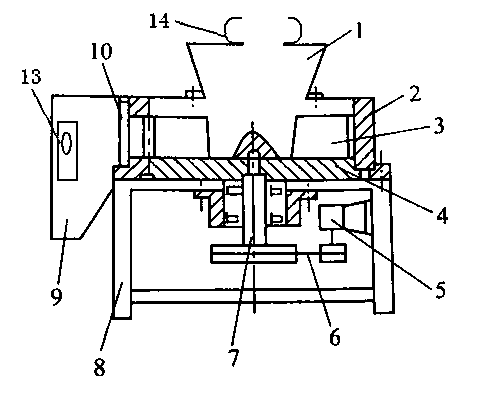

[0020] Example 1: Such as figure 1 , a bearing steel pipe cutting device, the cutting device includes a frame 8, a cylindrical shell 2 fixed on the frame 8, the cutting device also includes a power part, a transmission part and a cutting part, and the power part passes through The transmission part drives the cutting part to cut. The cutting part includes a knife holder 10, a blade, an impeller disc 4 and a blade 3, the blade is fixed on the knife holder 10, and the blade 3 surrounds the impeller disc. The technical solution completes the cutting of the steel pipe by setting blades and a combination of blades. The blades mainly ensure that the steel pipes enter the position of the blades stably to ensure cutting accuracy; the power component is set as the motor 5 . Used to provide power to complete the cutting work. The transmission part includes a rotating shaft 7 and a conveyor belt 6 arranged on the rotating shaft. The frame is also provided with a discharge device 9 a...

Embodiment 2

[0021] Example 2: Such as figure 1 , as an improvement of the present invention, the cutting device further includes an alarm component 13, and the alarm component 13 is configured as a buzzer and a sensor. Since the cutting of the steel pipe is not like other parts, when the machine breaks down, if it cannot be found and dealt with in time, it is easy to cause certain dangers. The alarm device is set on the discharge device. When it is detected that the discharge device cannot discharge normally, The buzzer automatically alarms to remind technicians to check and deal with related problems in time to avoid further expansion of danger. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

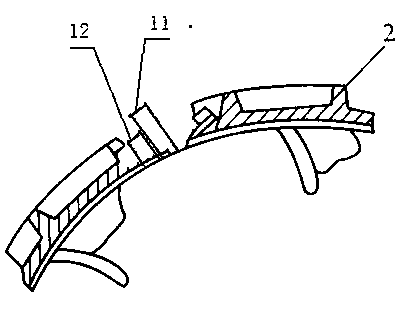

[0022] Example 3: Such as figure 1 , figure 2 , as an improvement of the present invention, the blades include a first blade 11 and a second blade 12, the first blade 11 and the second blade 12 are set as a group, and the length of the first blade 11 is the length of the second blade 12 1-1.5 times the length, in this technical solution, the first blade is used to cut the pipe, and the second blade is used to clean the groove of the pipe to ensure that the cut is not deformed, has no burrs, the cut is clean, and the processed surface quality is good . The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com