Magnesium alloy wheel forging-spinning composite forming method

A composite forming, magnesium alloy technology, applied in the direction of wheels, web wheels, vehicle parts, etc., can solve the problems of complex forming process, slow forging speed, low production efficiency, etc., to reduce casting defects, reduce machining allowance, The effect of material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

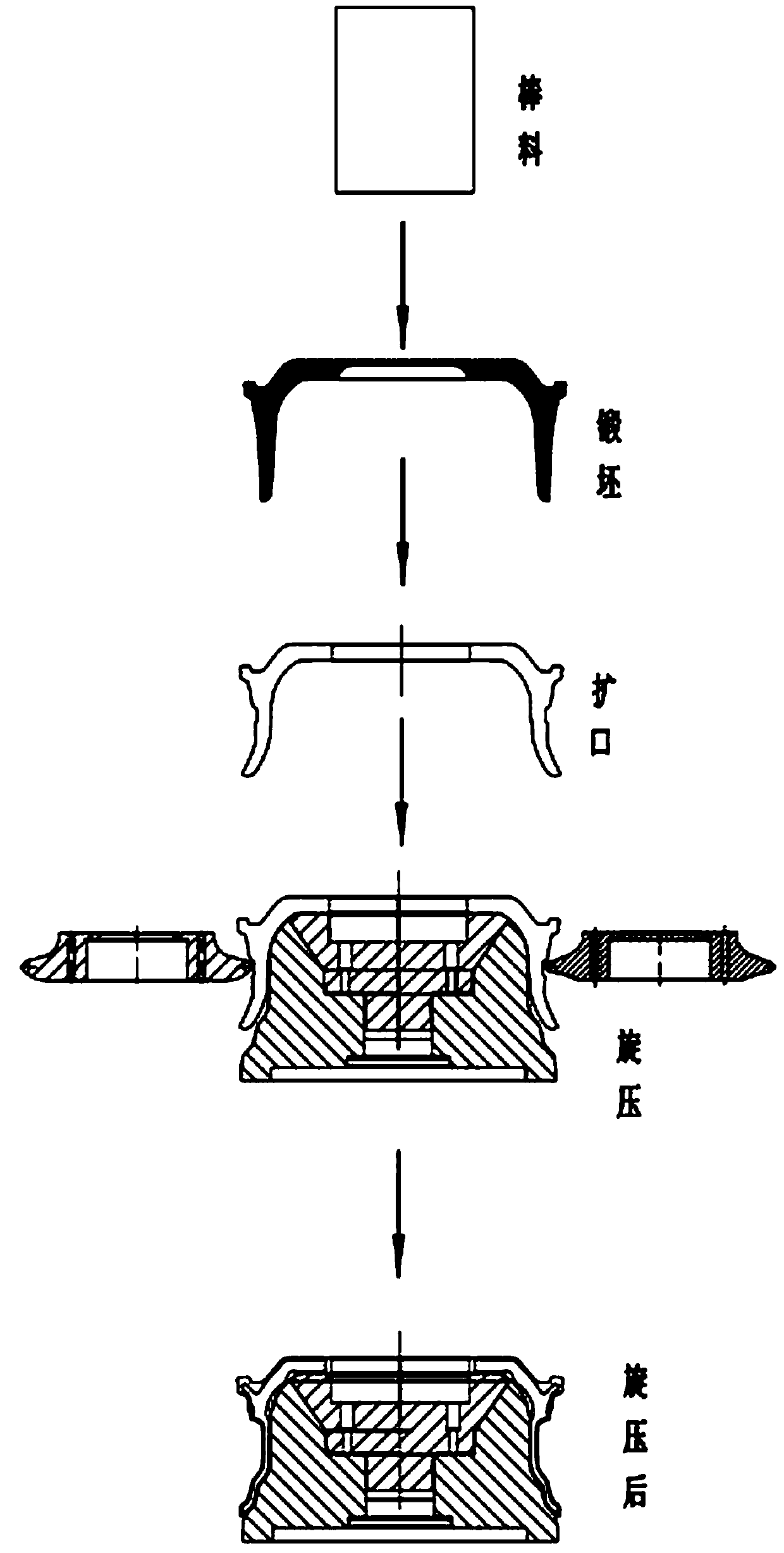

[0023] A magnesium alloy wheel forging and spinning composite forming method, comprising the following steps:

[0024] Preheat the magnesium alloy bar to 250°C in a heating furnace and keep it warm for 3 hours;

[0025] Heat the wheel forging die to 250°C in a die heating furnace for preheating, and keep it warm for 6 hours;

[0026] Take out the preheated wheel forging die and install it on the forging press;

[0027] Open the wheel forging die, and spray and lubricate the working cavity of the wheel forging die with oil-based graphite lubricant;

[0028] Put the wheel intermediate into the flaring mold for flaring;

[0029] After the flared wheel intermediate product is cooled, it is pre-machined, and the spinning is processed into the groove and the center hole;

[0030] The above wheel intermediate product was preheated to 200°C and held for 1 hour, and then spun on the CNC spinning equipment. The mold core temperature of the CNC spinning equipment was 150°C, the spindl...

Embodiment 2

[0033] A magnesium alloy wheel forging and spinning composite forming method, comprising the following steps:

[0034] Preheat the magnesium alloy bar to 300°C in a heating furnace and keep it warm for 3.5 hours;

[0035] Heat the wheel forging die to 300°C in a die heating furnace for preheating, and keep it warm for 6.5 hours;

[0036] Take out the preheated wheel forging die and install it on the forging press;

[0037] Open the wheel forging die, and spray and lubricate the working cavity of the wheel forging die with oil-based graphite lubricant;

[0038] Put the preheated magnesium alloy bar into the opened wheel forging die, carry out forging at a pressing speed of 5 mm / s, and demould to obtain the intermediate product of the wheel;

[0039] Put the wheel intermediate into the flaring mold for flaring;

[0040] After the flared wheel intermediate product is cooled, it is pre-machined, and the spinning is processed into the groove and the center hole;

[0041] The ab...

Embodiment 3

[0044] A magnesium alloy wheel forging and spinning composite forming method, comprising the following steps:

[0045] Preheat the magnesium alloy bar to 350°C in a heating furnace and keep it warm for 4 hours;

[0046] Heat the wheel forging die to 350°C in a die heating furnace for preheating, and keep it warm for 7 hours;

[0047] Take out the preheated wheel forging die and install it on the forging press;

[0048] Open the wheel forging die, and spray and lubricate the working cavity of the wheel forging die with oil-based graphite lubricant;

[0049] Put the preheated magnesium alloy bar into the opened wheel forging die, carry out forging, the pressing speed is 8mm / s, and demold to obtain the intermediate product of the wheel;

[0050] Put the wheel intermediate into the flaring mold for flaring;

[0051] After the flared wheel intermediate product is cooled, it is pre-machined, and the spinning is processed into the groove and the center hole;

[0052] The above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com