Traveling mechanism for ship and ocean engineering deck machinery

A walking mechanism and marine engineering technology, which is applied to ship components, ship construction, ships, etc., to reduce risks, improve operating range and mobility, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and example the present invention will be further described:

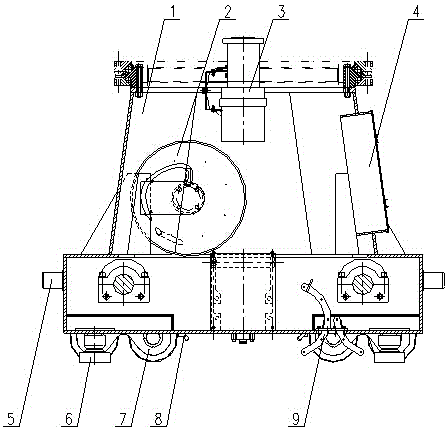

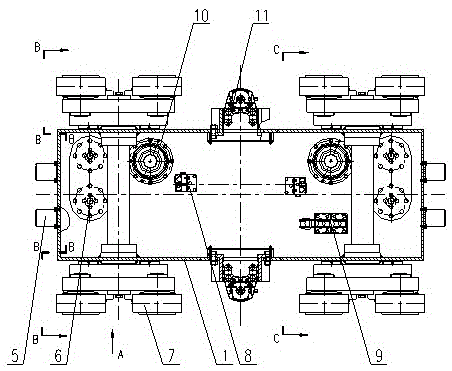

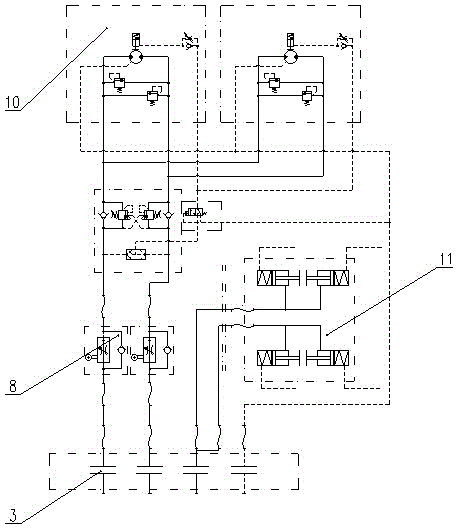

[0019] like figure 1 , figure 2 As shown, the traveling mechanism for ships and marine engineering deck machinery of the present invention consists of a walking frame 1, a cable reel 2, an electro-hydraulic slip ring 3, a hatch cover assembly 4, a buffer 5, a guide wheel group 6, and a roller group 7 , limit valve 8, pay-off frame 9, travel drive device 10, rail clamp 11 and other components.

[0020] The walking frame 1 is the main structural part of the walking mechanism, and is used to install the cable reel 2, the electro-hydraulic slip ring 3, the hatch cover assembly 4, the buffer 5, the guide wheel group 6, the roller group 7, the limit valve 8, the release Wire rack 9, travel drive device 10, rail clamp 11. The cable reel 2 is installed inside the walking frame 1, and a constant tension is applied to the power cable during the walking process to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com