A graphite powder quantitative delivery device

A conveying device and powder technology, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of inability to convey light weight, poor fluidity, etc., and achieve poor fluidity, powder drop point and shape. Controllable effect of powder feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

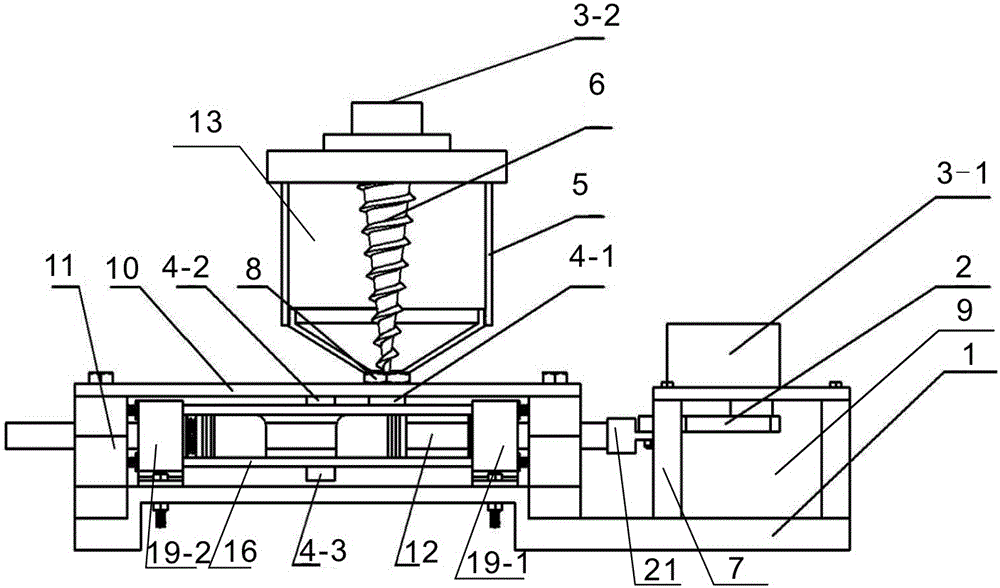

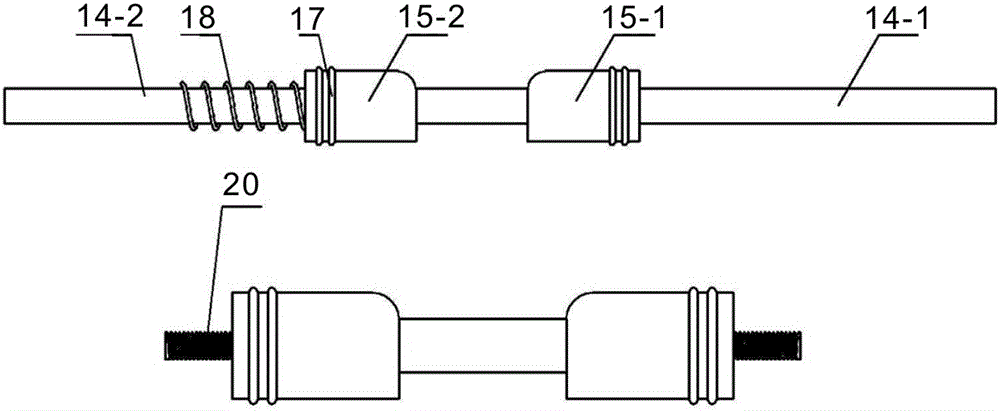

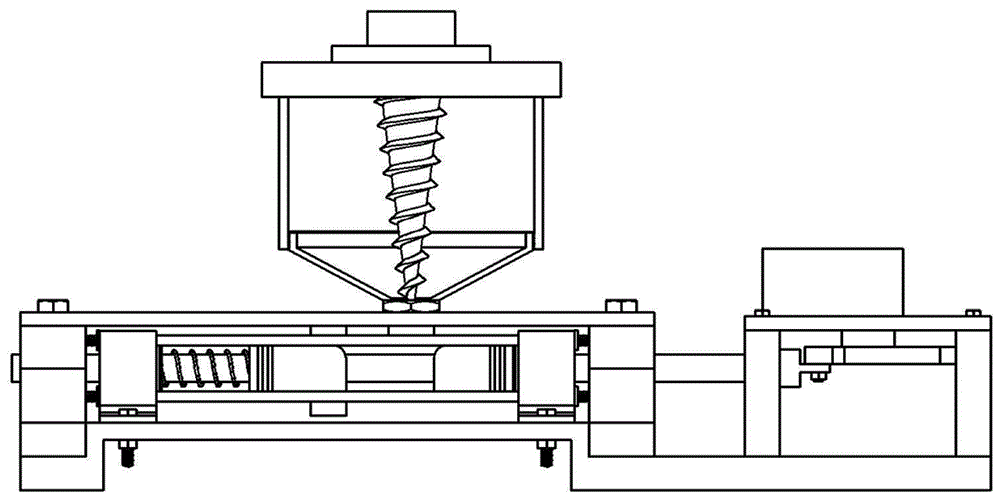

[0031] like figure 1 , figure 2 The graphite powder quantitative delivery device provided by the present invention comprises: 1. support, 2. cam, 3-1, 2. stepper motor, 4-1, 2, 3, 4. support pad, 5. feed bin, 6 .Agitator, 7. Fixed frame, 8. Lock nut, 9. Reciprocating drive mechanism, 10. Bracket plate, 11. Sliding bearing seat, 12. Plunger type powder feeding mechanism, 13. Screw powder feeding mechanism, 16 .Cylinder block, 19. End cover, 21 Cam roller, 14-1, 2. Plunger rod, 15-1, 2. Plunger, 17. O-ring, 18. Compression spring, 20. Intermediate connecting rod .

[0032] A graphite powder quantitative conveying device, the device includes a raised bracket 1, a reciprocating drive mechanism 9, a plunger type powder feeding mechanism 12 and a screw powder feeding mechanism 13, and the raised part of the bracket 1 is provided with a plunger type The powder feeding mechanism 12, the plunger type powder feeding mechanism 12 is provided with a support pad 4-1, the support pad 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com