Activated carbon catalytic ozonation device and sewage treatment process thereof

An ozone oxidation and activated carbon technology, applied in the oxidation of water/sewage treatment and other directions, can solve the problems of reducing ozone utilization efficiency, affecting the ability of activated carbon to catalyze ozone oxidation, low porosity, etc., and achieving prolonged and enhanced contact time and reaction time. ability, the effect of increasing the void ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

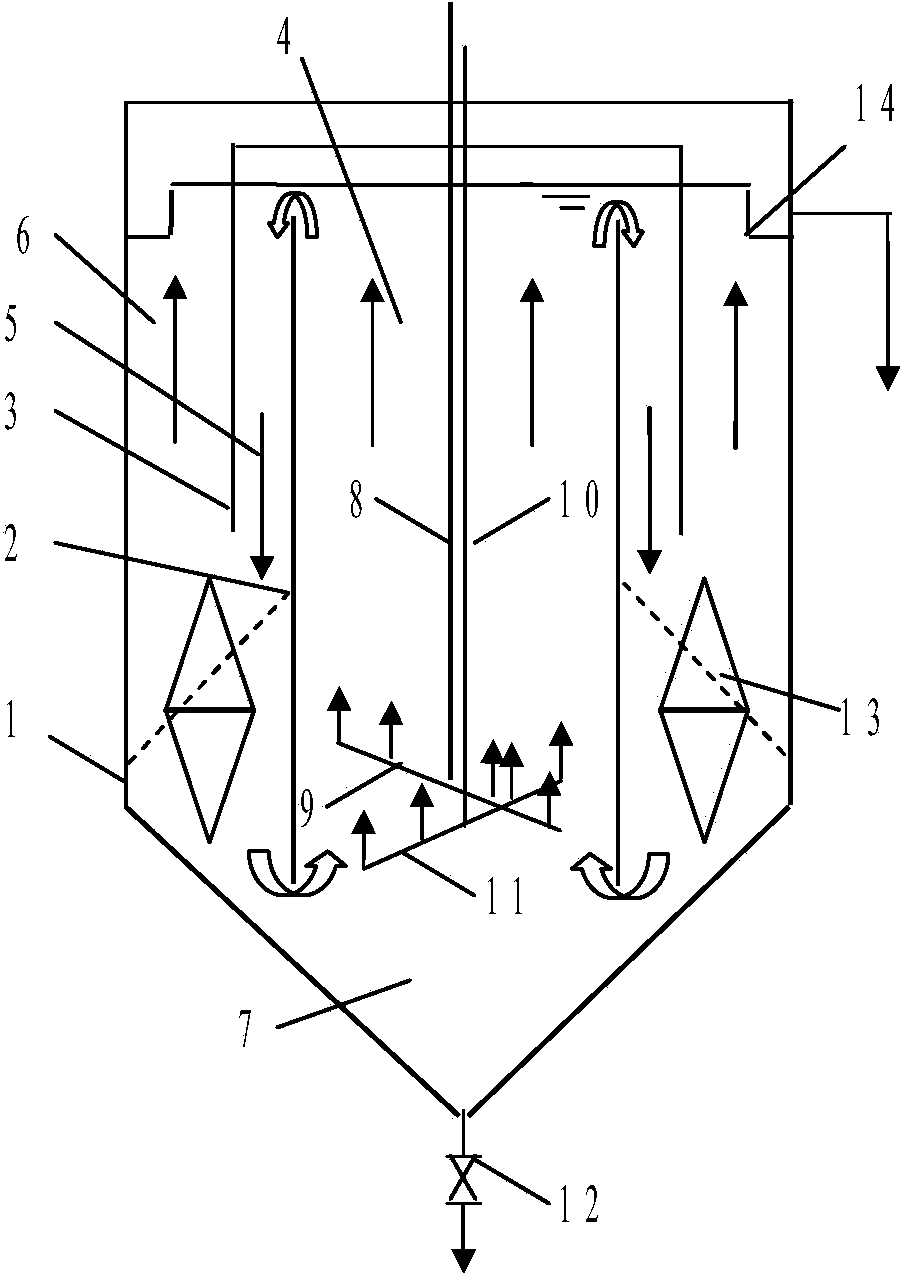

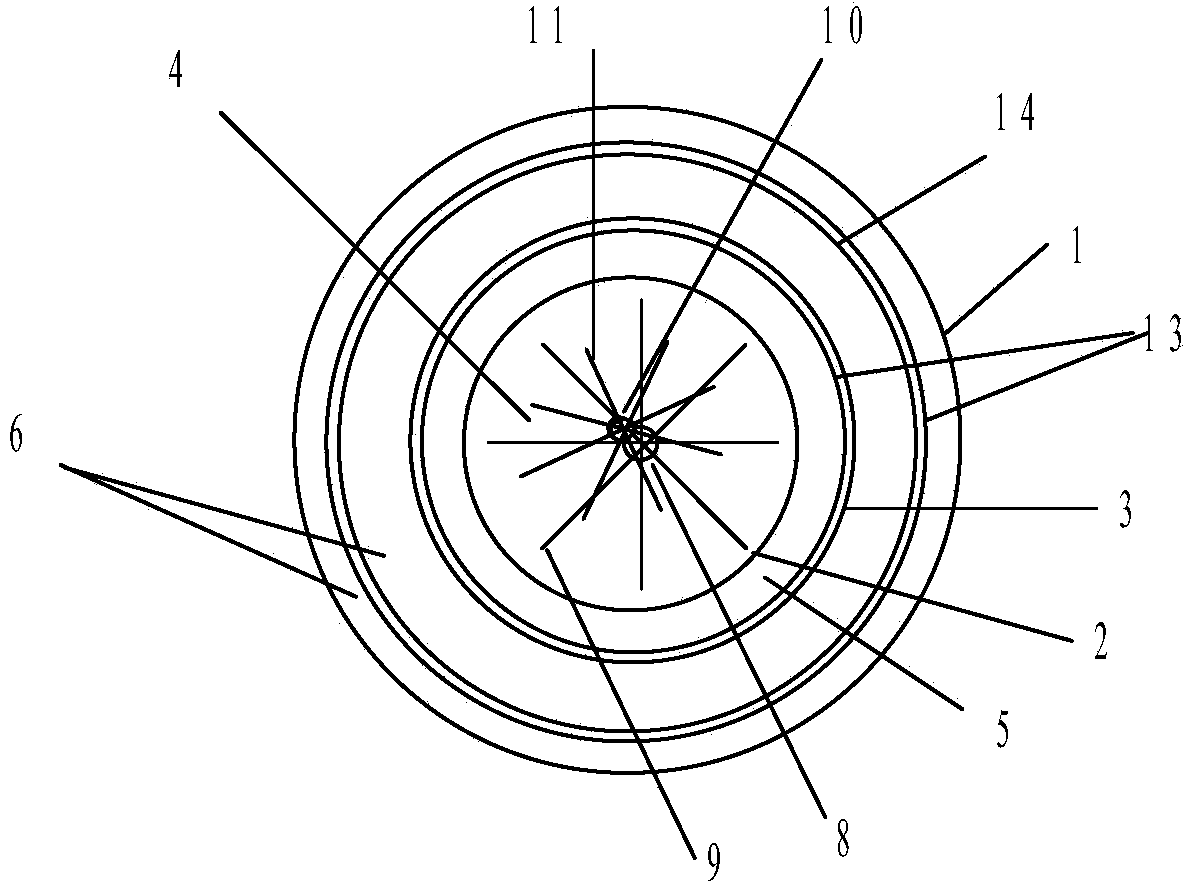

[0031] The activated carbon catalytic ozonation device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Such as figure 1 , 2As shown, an activated carbon catalytic ozone oxidation device includes a reaction tank 1, the upper part of the reaction tank 1 is cylindrical, the lower part is an inverted cone, the upper part is 6.5m high, the diameter is 2.1m, and the lower part is 1.05m high. The interior of the reaction pool 1 is provided with two coaxial and vertical guide cylinders, which are respectively the inner cylinder 2 located inside and the outer cylinder 3 on the periphery. The flow reaction zone 4, the downflow reaction zone 5 and the separation zone 6, wherein the area surrounded by the inner cylinder 2 is the upflow reaction zone 4, the question between the inner cylinder 2 and the outer cylinder 3 is the downflow reaction zone 5, and the outer cylinder 3 and the reaction A separation zone 6 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com