Treating method of high-ammonia-nitrogen mother liquor wastewater in MCP (methyl cyclopentenolone) production

A kind of methylcyclopentenol ketone, treatment method technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

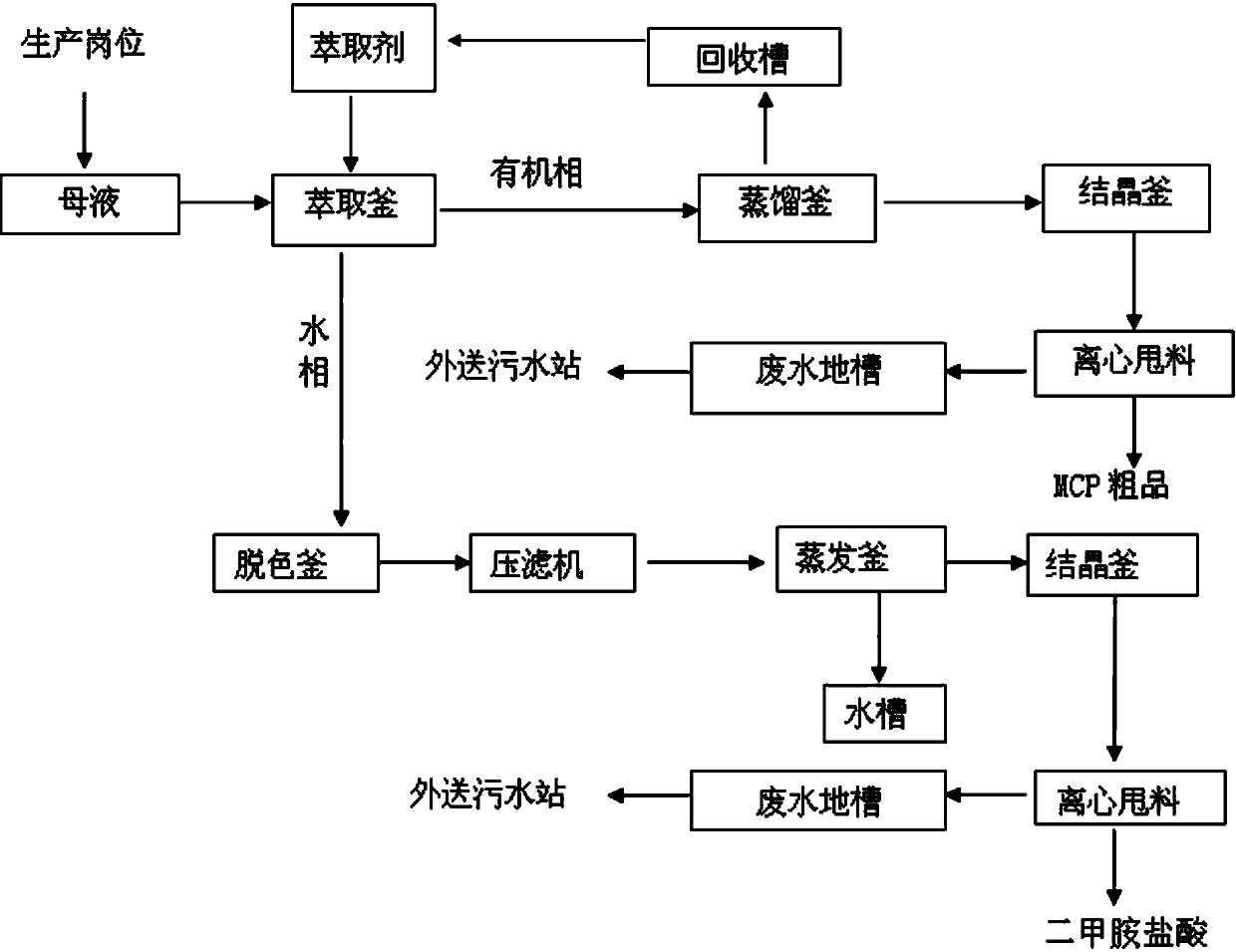

Image

Examples

Embodiment 1

[0015] A treatment method for high ammonia nitrogen mother liquor wastewater in the production of methylcyclopentenolone (MCP), characterized in that it comprises the following steps:

[0016] a. Send the high ammonia nitrogen mother liquor produced by the production station into the mother liquor tank for metering, and the volume of the mother liquor is 1m 3 , use the mother liquid pump to pump into the extraction kettle, add 250L of extractant (chloroform), stir for 30 minutes, let stand for 3 hours, separate the layers, and separate the aqueous phase and the organic phase;

[0017] b. Pump the organic phase into the distillation pot for vacuum distillation, keep the pressure at -0.092-0.096MPa, and keep the temperature at 40-45°C to recover the extractant. The distilled extractant (chloroform) is condensed and then put into the recovery tank It can be recycled, and the residue is further extracted and utilized;

[0018] c. Add 150L of mother liquor to the distillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com